Soft waste full-automatic packaging system

A fully automatic and waste-free technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of loose and irregular packaging materials, high labor intensity, and small package weight, so as to reduce manual labor intensity and high degree of automation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

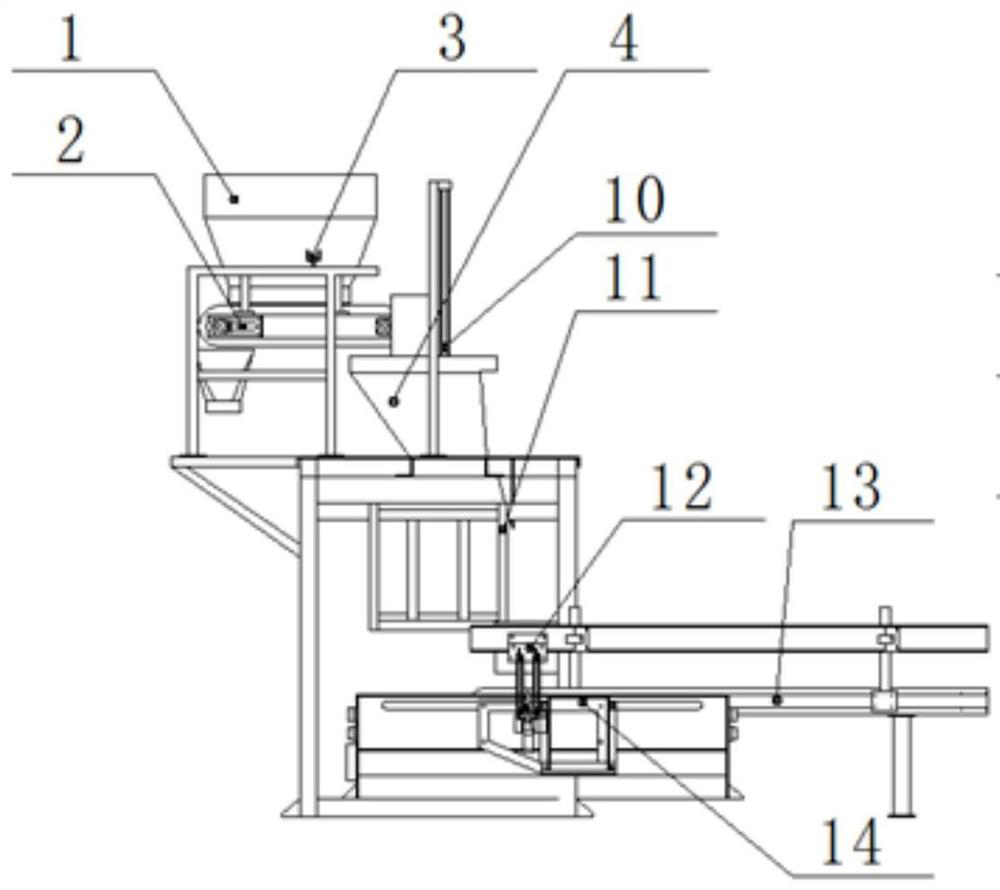

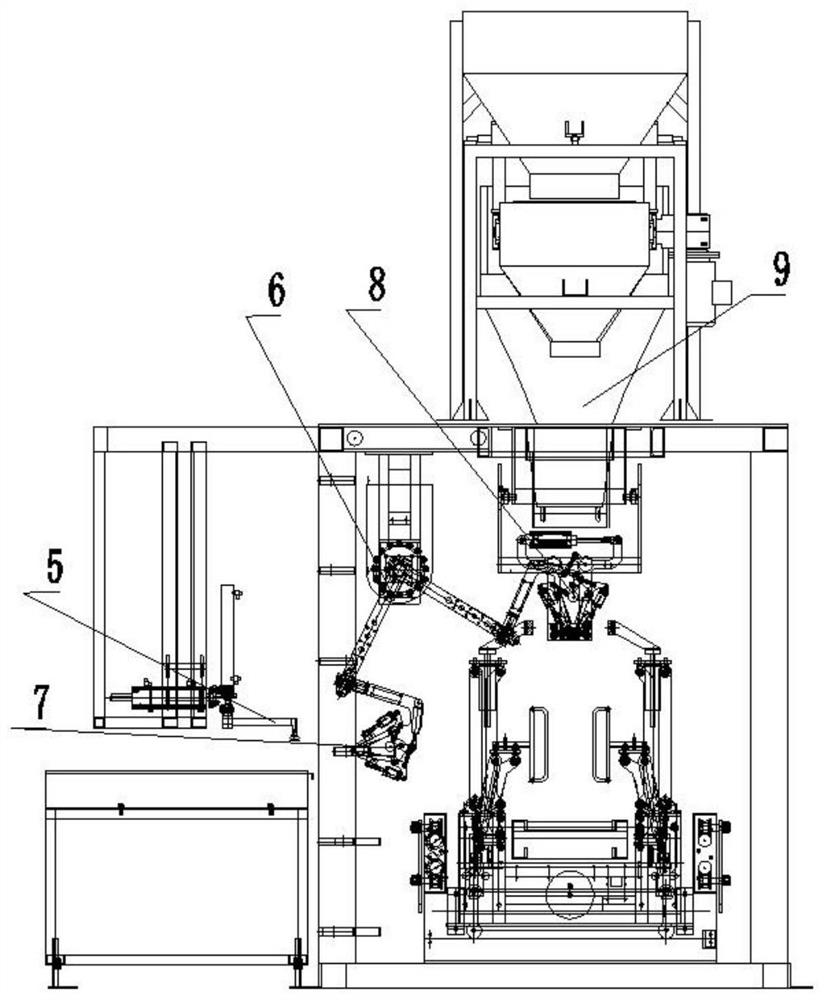

[0027] Such as figure 1 , figure 2 As shown, it includes a weighing and metering and feeding system, a bagging system, a compacting system, a filling processing system and an auxiliary system. 2. The weighing system 3 and the discharge hopper 4 are composed, the feeding belt conveyor 2 and the weighing system 3 are located under the silo 1, and the discharge hopper 4 is located on the side of the end of the feeding belt conveyor 2;

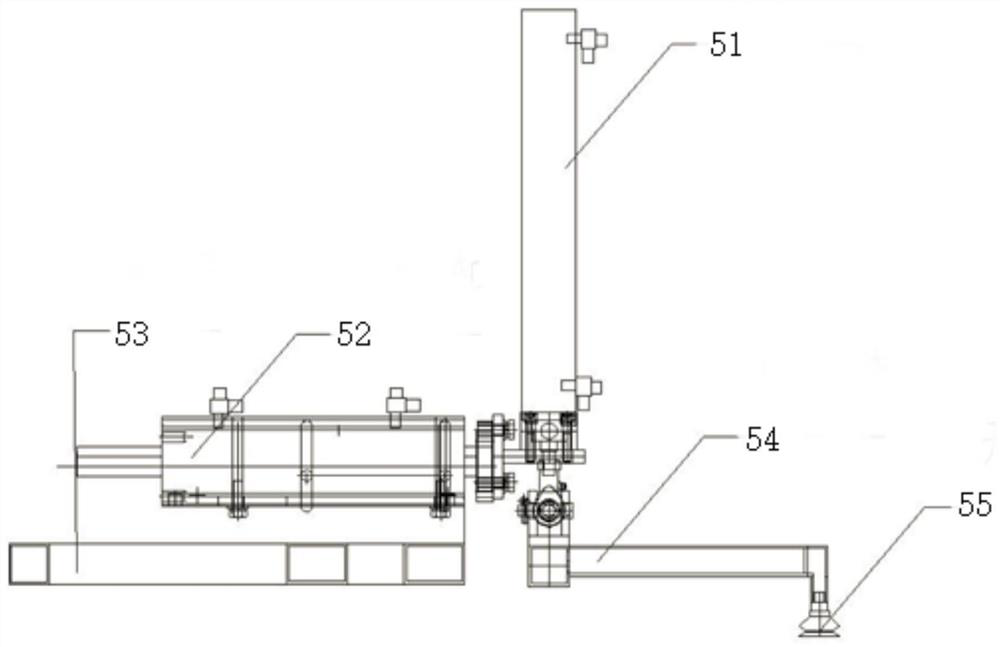

[0028] The bagging system is composed of a bagging mechanism 5, a pushing mechanism 6, a bag supporting mechanism 7 and a guiding mechanism 8;

[0029] Described compaction system is made up of material chute 9, compaction mechanism 10 and frame 11, and material chute 9 is positioned at the bottom of feed bin 1, and compaction mechanism 10 is positioned at the bottom of material chute 9, and frame 11 is positioned at the bottom of compaction mechanism 10;

[0030] The filling processing system is composed of a bag opening processing system 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com