Dynamic characteristic adjustable micro-motion platform

A technology of dynamic characteristics and micro-motion, which is applied in the direction of worktables, large fixed members, metal processing machinery parts, etc., and can solve problems such as resonance points and inoperability of micro-motion platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

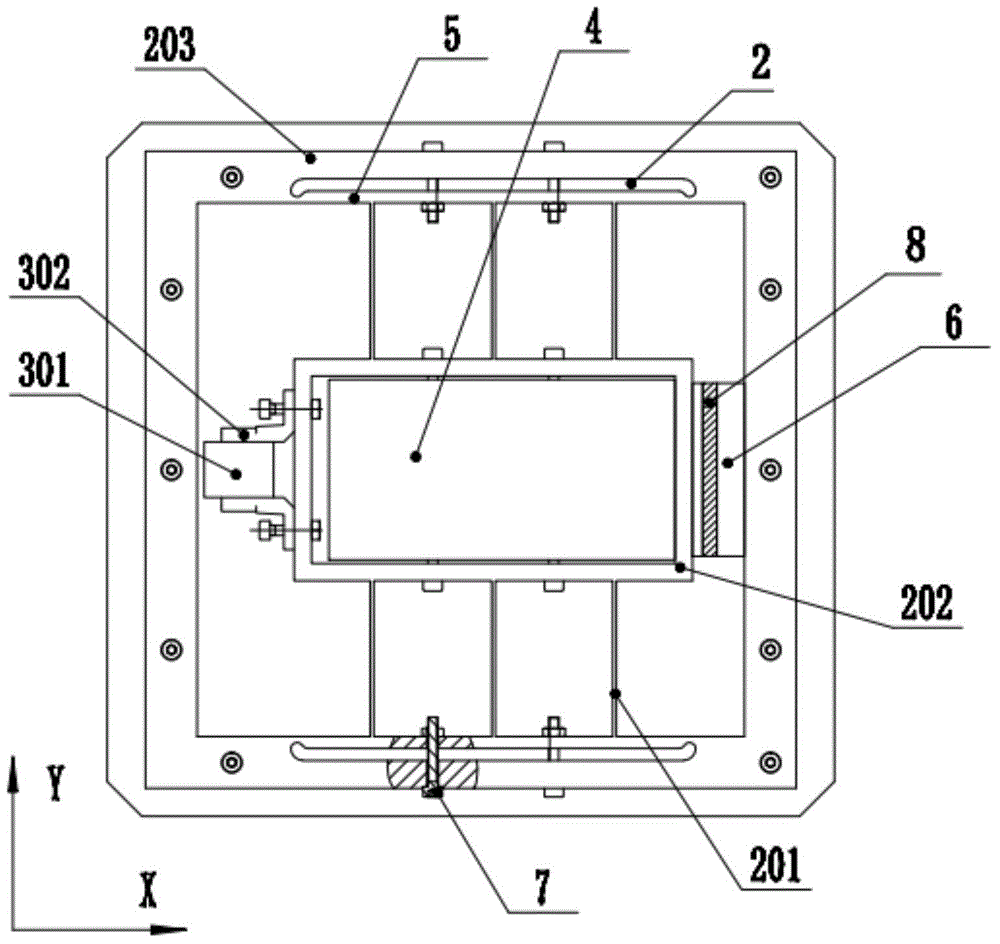

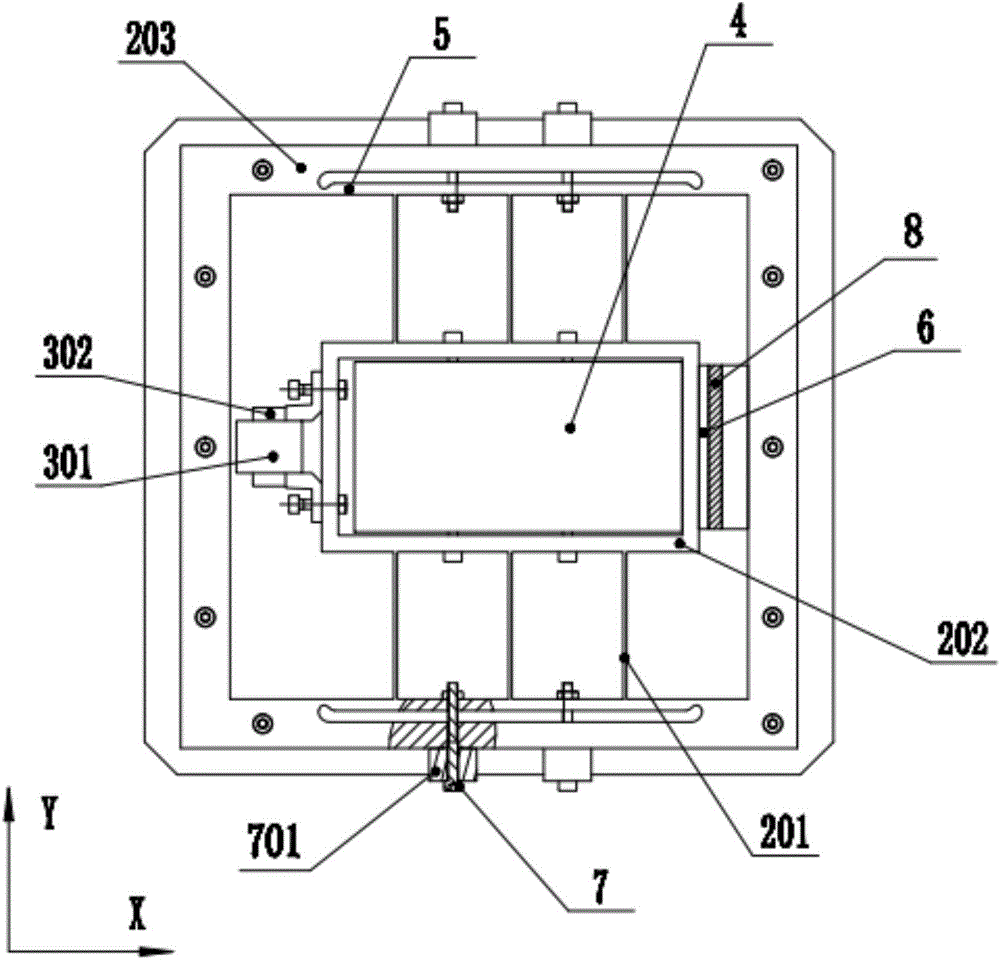

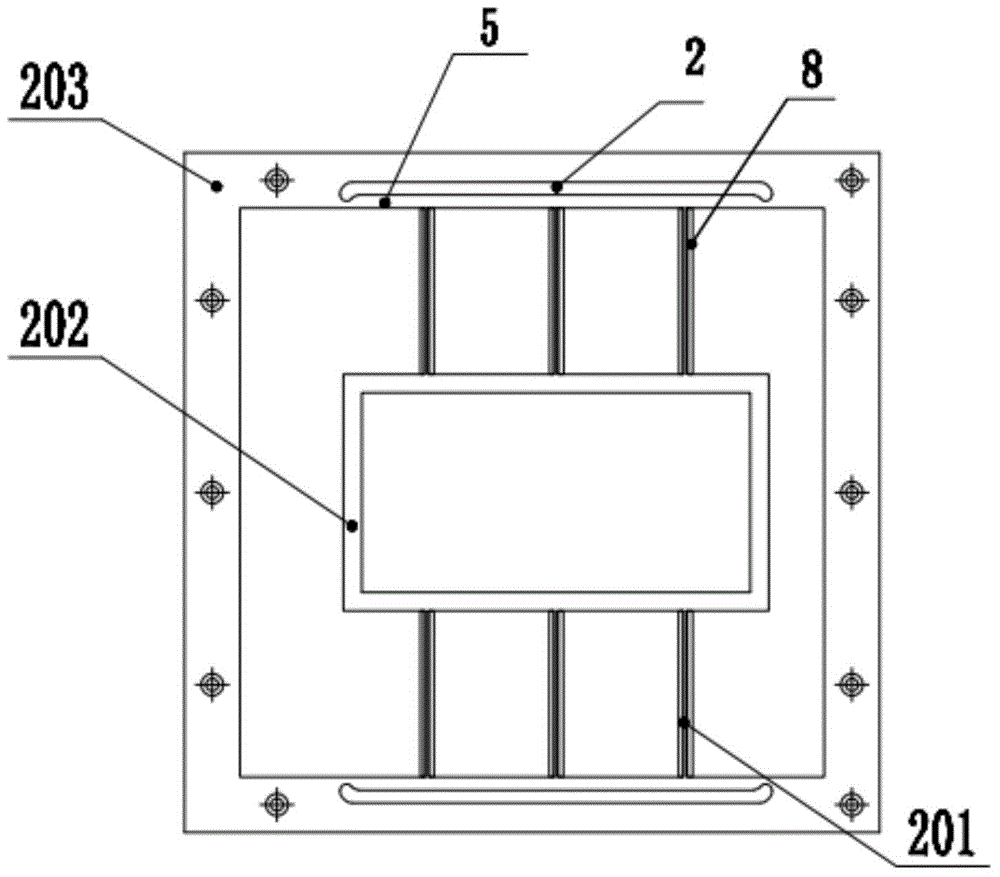

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] Dynamic characteristic adjustable micro-motion platform, including base 1, shrapnel group 201, micro-motion sub-platform 202, outer frame 203, driver, micro-motion workbench 4, tension adjustment mechanism 7, displacement sensor 6 and variable damper 8;

[0028] Both sides of the micro-motion sub-platform 202 are connected to the inner wall of the outer frame 203 through the shrapnel group 201, the shrapnels in the shrapnel group 201 are arranged in parallel, and the length direction of the shrapnel is perpendicular to the micro-movement The direction of motion of the sub-platform 202;

[0029] The outer frame 203 is rigidly fixed to the base 1, and the micro-motion worktable 4 is rigidly fixed to the micro-motion sub-platform 202;

[0030] The driver includes a stator 301 and a mover 302, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com