Experimental device and method for simulating wellbore annulus drilling fluid flow characteristics

A technology for simulating wellbore flow characteristics and wellbore. It is used in fluid dynamics tests, measuring devices, and testing of machine/structural components. It can solve the problems of few experimental research results, and achieve the effect of strong operability and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

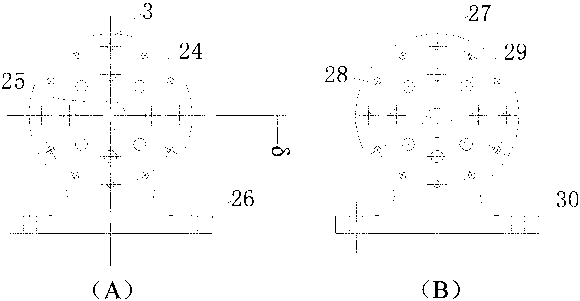

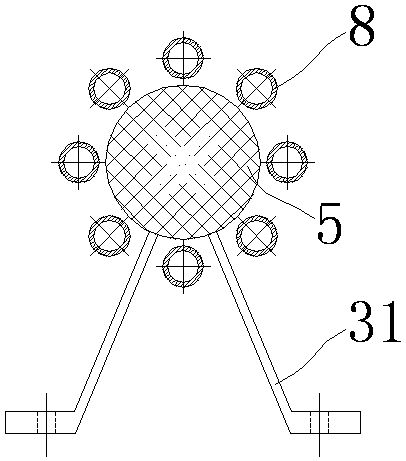

[0026] When simulating the drilling fluid flow characteristics in the wellbore annulus under the drilling condition of the horizontal well section, firstly, the angle formed by the support table 10 and the horizontal line is adjusted to 0° by controlling the lifting motor 13 and the telescopic rod 12; then, the mud circulation valve 17 is opened , the mud input valve 18 and the mud output valve 19, open the mud pump 15 to pump mud into the annular space between the simulated drill pipe 2 and the outer cylinder 1; the mud enters the annular space after being rectified by the front splitter 8, and passes through the annular space again It is collected by the rear splitter 9, and then discharged into the mud tank 16 through the hose; the mud input flow is adjusted and controlled through the mud input valve 18, and the mud flow value is read from the flow meter 14 and recorded; after the mud forms a stable cycle, Turn on the rotary motor 5 to drive the simulated drill pipe 2 to rot...

specific Embodiment 2

[0027] When simulating the drilling fluid flow characteristics in the wellbore annulus under the drilling conditions of the vertical well section, firstly, the angle formed by the support table 10 and the horizontal line is adjusted to 90° by controlling the lifting motor 13 and the telescopic rod 12; then, the mud circulation valve 17 is opened , the mud input valve 18 and the mud output valve 19, open the mud pump 15 to pump mud into the annular space between the simulated drill pipe 2 and the outer cylinder 1; the mud enters the annular space after being rectified by the front splitter 8, and passes through the annular space again It is collected by the rear splitter 9, and then discharged into the mud tank 16 through the hose; the mud input flow is adjusted and controlled through the mud input valve 18, and the mud flow value is read from the flow meter 14 and recorded; after the mud forms a stable cycle, Turn on the rotary motor 5 to drive the simulated drill pipe 2 to rot...

specific Embodiment 3

[0028] When simulating the drilling fluid flow characteristics in the annulus of the wellbore under the drilling condition of the deviated section, firstly, adjust the angle formed by the support table 10 and the horizontal line to a certain acute angle by controlling the lifting motor 13 and the telescopic rod 12; then, turn on the mud circulation Valve 17, mud input valve 18 and mud output valve 19, open the mud pump 15 to pump mud into the annular space between the simulated drill pipe 2 and the outer cylinder 1; the mud enters the annular space after being rectified by the front splitter 8, and passes through the annular space After that, it is collected by the rear splitter 9, and then discharged into the mud tank 16 through the hose; the mud input flow is adjusted and controlled by the mud input valve 18, and the mud flow value is read from the flow meter 14 and recorded; when the mud forms a stable cycle Finally, turn on the rotary motor 5 to drive the simulated drill pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com