Column nail type high-pressure grinding roller roll surface and production method thereof

A technology of high-pressure roller mills and production methods, applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of long production time, waste, high cost, etc., and achieve the effects of reducing production time limit, reducing production cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

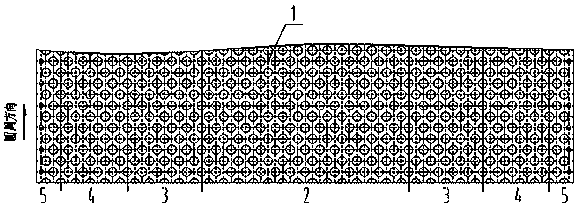

[0036] A method for producing a stud-type high-pressure roller mill roll surface, the roll surface is composed of a roll cover matrix and studs embedded on the surface, and the roll cover 1 includes a working layer and a core layer, including the following steps:

[0037] (1) The working layer material and the core layer material are separately smelted into molten steel. In step (1), the temperature for molten steel refining of the working layer material and the core layer material is 1400-1600°C, and the mass percentages of the main components of the working layer material are C: 1.5-1.7%, Cr: 11.0-12.5% , Mo:0.4~0.6%, V:0.2~0.3%, Si:≤0.4%, Mn:≤0.4%, Ni:≤0.25%, Cu:≤0.3%, S:≤0.02%, P:≤0.02% , the rest are Fe and impurities to be controlled; the main components of the core material are C: 1.0-1.5%, Si: 2.2-2.6%, Mn: 0.5-0.8%, Cr: ≤0.5%, Ni: ≤0.5%, Mo: ≤0.2%, S: ≤0.02%, P: ≤0.02%, and the rest are Fe and impurities to be controlled.

[0038] (2) After the molten steel of the w...

Embodiment 2

[0045] A stud-type high-pressure roller mill roll surface is composed of a roller sleeve base and studs inlaid on the surface. The roll sleeve contains a working layer and a core layer. The working layer is made of high-chromium steel with a surface hardness of HRC45-60. Compressive strength ≥ 1500MPa, deflection ≥ 2mm; the core layer is made of graphite steel, surface hardness HRC35 ~ 45, tensile strength ≥ 600MPa, elongation ≥ 2%; the roll surface will be divided into three areas according to the roll width, five The central part is the first zone, and its symmetrical sides are the second zone, the third zone, and the fourth zone in turn; the Co content of the studs in the first zone is 8wt% ~ 25wt%, the hardness is HRA86 ~ HRA88, and the other zones The Co content of the studs is 8wt%-25wt%, the hardness decreases by HRA0.5-HRA2 in turn, and the metallographic detection of all studs reaches above A02B00C00E00.

[0046] In the process of improving the roll surface, it was fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com