Mop with liquid-sprayer

A mop and mop handle technology, which is applied in the field of sanitary ware, can solve the problems such as the inability to adjust the spray angle, the inability to meet the needs of fine-tuning, and the limitation of the spray range, and achieve the effect of expanding the spray angle range, compact structure, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

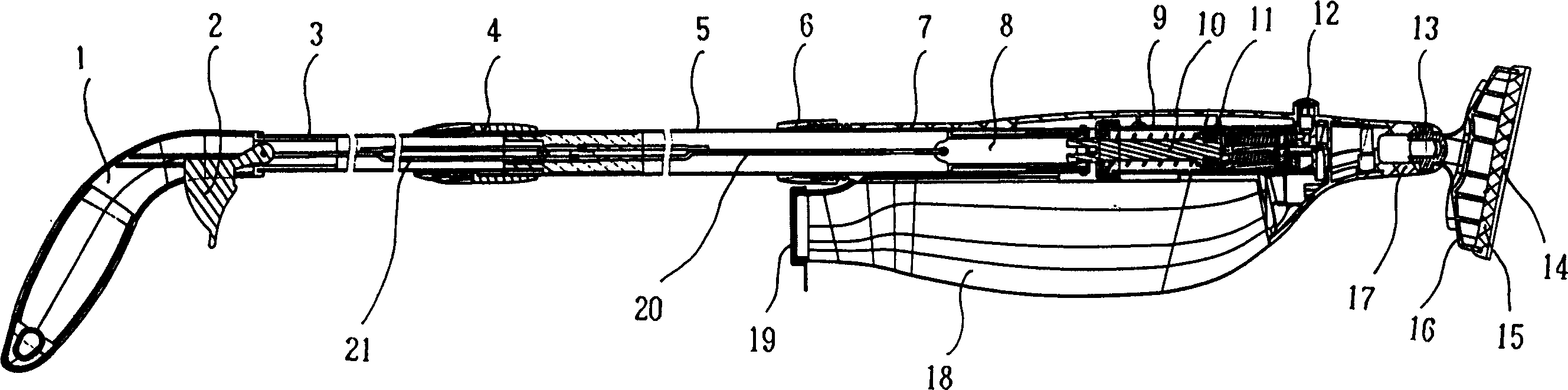

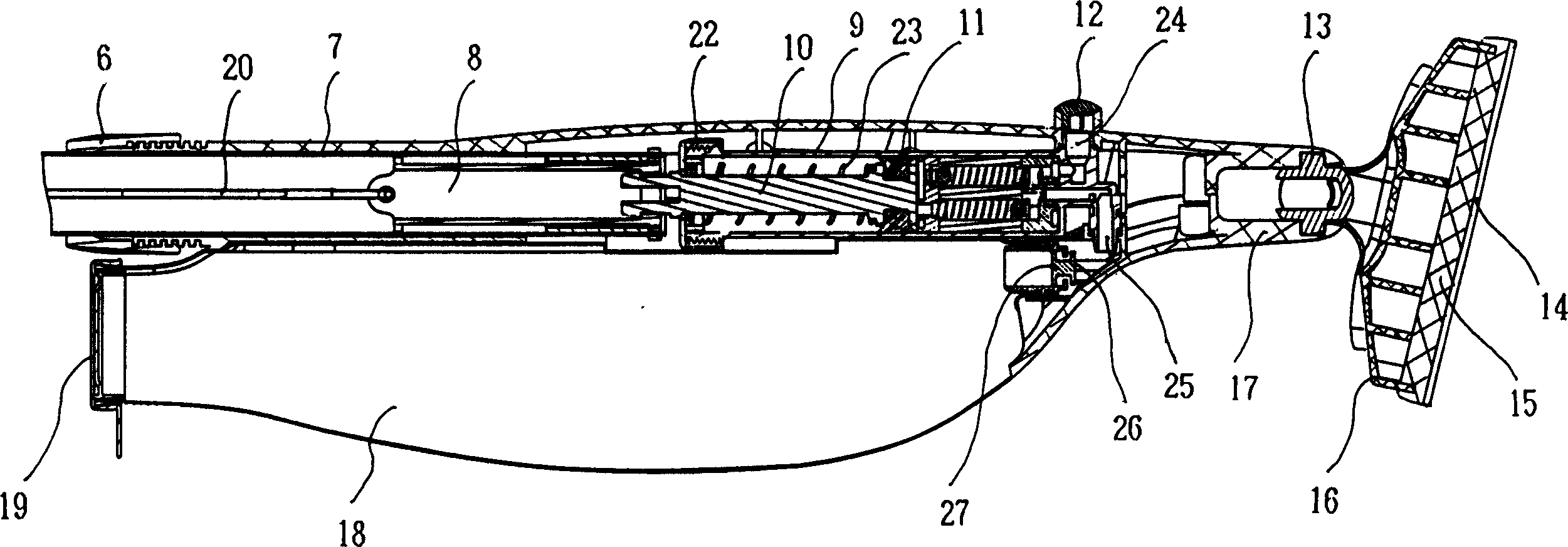

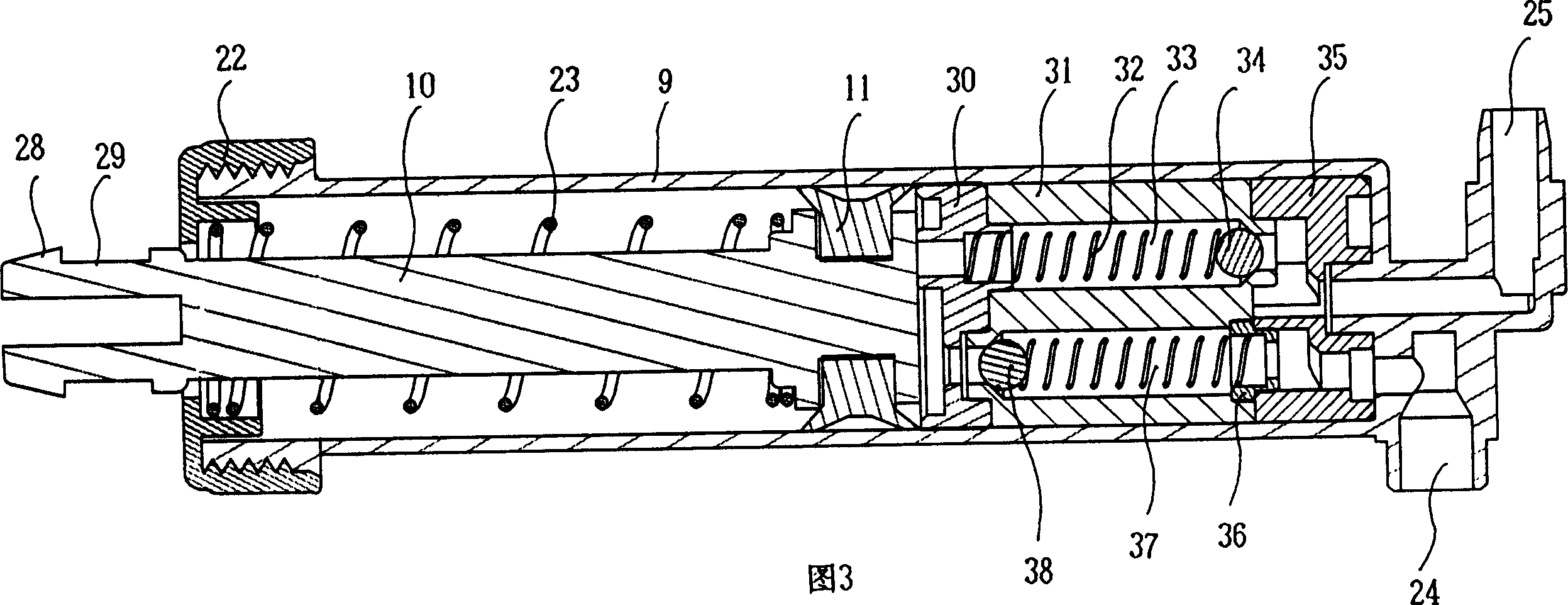

[0018] Such as figure 1 - As shown in Figure 3, the liquid spray mop is composed of a mop handle, a liquid spray device and a cleaning part.

[0019] The mop handle consists of an inner rod 3 and an outer rod 5 that are mutually fitted and retractable. After elongation, the male and female locking sleeves 4 are locked. 1 The lower side has a window for the pulling range of the liquid spray switch 2 in the liquid spray device.

[0020] The liquid spraying device is made up of operating mechanism, liquid suction and discharge mechanism, liquid storage bottle 18.

[0021] The operating mechanism is located in the hollow inner rod 3 and the outer rod 5 of the mop handle, and one end of the liquid spray switch 2 is exposed for pulling manipulation, and the inner end is connected to the front drag hook 21, the front drag hook 21 and the rear drag hook 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com