Preparation method of ferrous metal organic framework material and application of ferrous metal organic framework material

A metal-organic framework and ferrous salt technology, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of poor practicability, high cost, and resistance to sulfur-containing components Ability and other issues, to achieve the effect of enhanced applicability, weakened binding force, and strong anti-sulfur pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

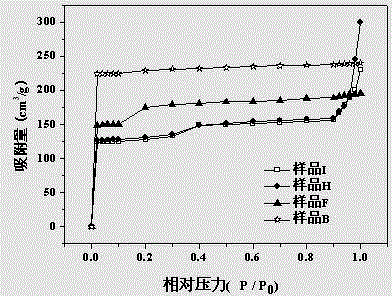

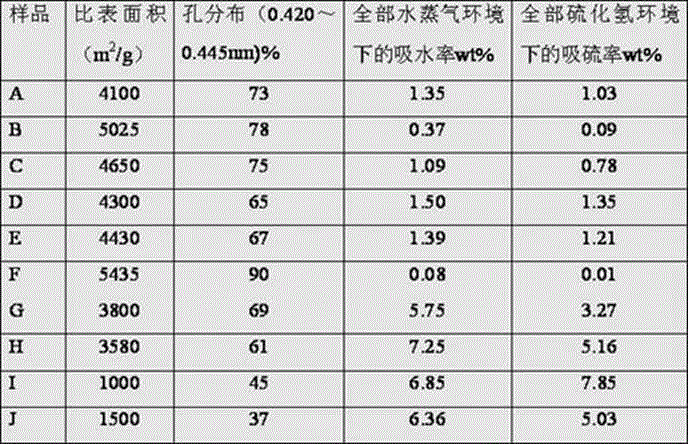

Image

Examples

Embodiment 1

[0031] First weigh 1.39g FeSO 4 ·7H 2 O and 2.16g 2,6-naphthalene dicarboxylic acid were then dissolved in 18mL deionized water, followed by adding 4.5g tartaric acid and 1.8g acetic acid, and stirring for 2h at a speed of 700rpm / min on a magnetic constant temperature stirrer to obtain a precursor solution. Then put the precursor solution into a stainless steel autoclave lined with polytetrafluoroethylene, seal it and put it into a temperature-programmed furnace for hydrothermal reaction. Then the temperature was lowered from 160°C to room temperature at 1°C / min. The obtained precipitate was washed twice with deionized water, N,N-dimethylformamide and acetone respectively, and then centrifuged at 2000rpm / min for 20min, and the bottom product was filtered and moved to a blast drying oven. Dry at 100° C. for 5 hours to obtain the iron metal organic framework material A of the present invention.

Embodiment 2

[0033] Compared with Example 1, FeSO 4 ·7H 2 O was 4.17g, and other operating conditions and material composition were unchanged, and iron-containing metal-organic framework material B was obtained.

Embodiment 3

[0035] Compared with Example 1, FeSO 4 ·7H 2 O was 5.56g, and the other operating conditions and material composition were unchanged, and the iron-containing metal-organic framework material C was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com