Full-automatic pneumatic steel coil bundler

A baling machine, fully automatic technology, applied to the parts of the bundling machine, bundling materials, paper/cardboard containers, etc., can solve the problems of poor reliability and complicated control, and achieve short baling time, simple operation, and mechanical parameters. Small fluctuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

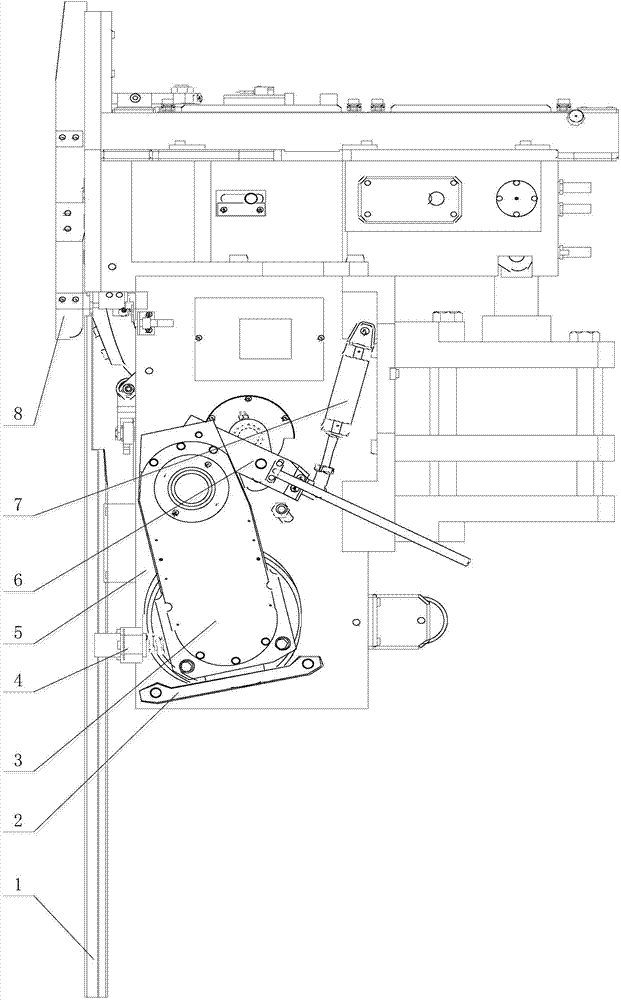

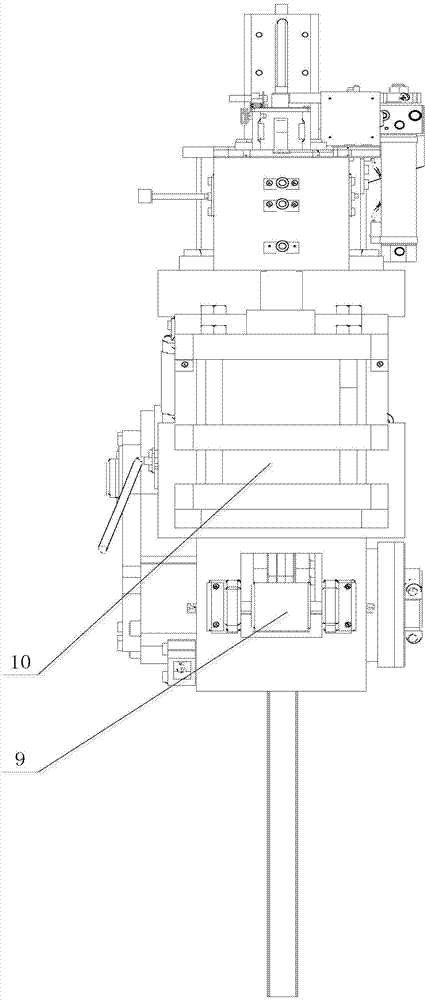

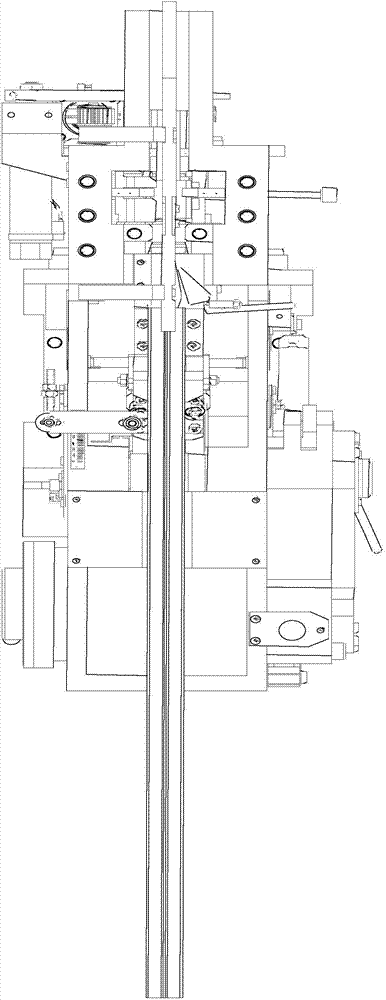

[0032] As shown in the accompanying drawings, a fully automatic pneumatic steel coil strapping machine mainly completes a series of actions such as feeding, tensioning, and cutting off the steel strip, including: a housing 5, which carries the matrix of each part of the strapping machine, and Provide connection interfaces for other auxiliary equipment (such as outer guide rail 1, buckle storage box 16, etc.); the claw mechanism completes a series of actions such as clamping, clamping and cutting the steel belt of the lock; the steel belt introduction mechanism is used to Control the accurate positioning of the steel belt to the lock position, and assist the introduction, positioning, and buckle of the steel belt; the steel belt pumping mechanism, the pneumatic drive motor drives the active rotation, and the two wheels rely on friction to send th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com