Method for preparing three-band-gap chromium-doped copper-zinc-tin-sulfur solar cell thin film material through electro-deposition method

A solar cell, copper-zinc-tin-sulfur technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as Cr-doped CZTS triple-bandgap thin-film solar cell materials, etc., and achieve controllable film composition and surface The appearance is dense and flat, and the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

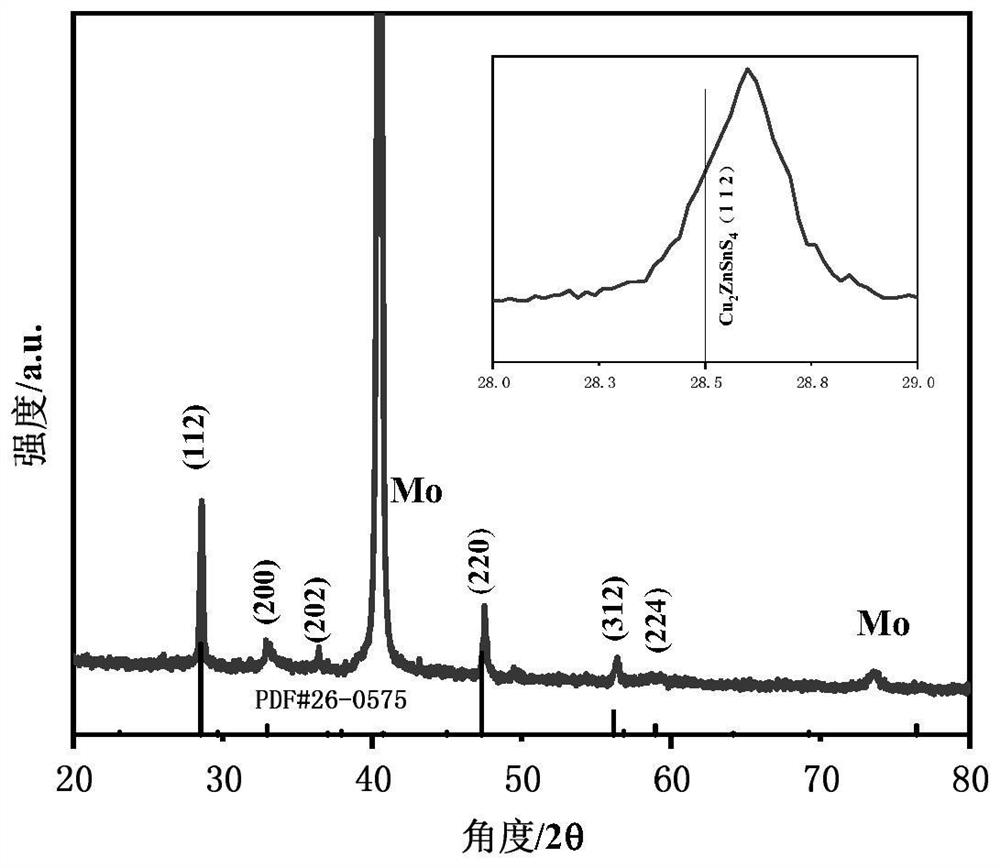

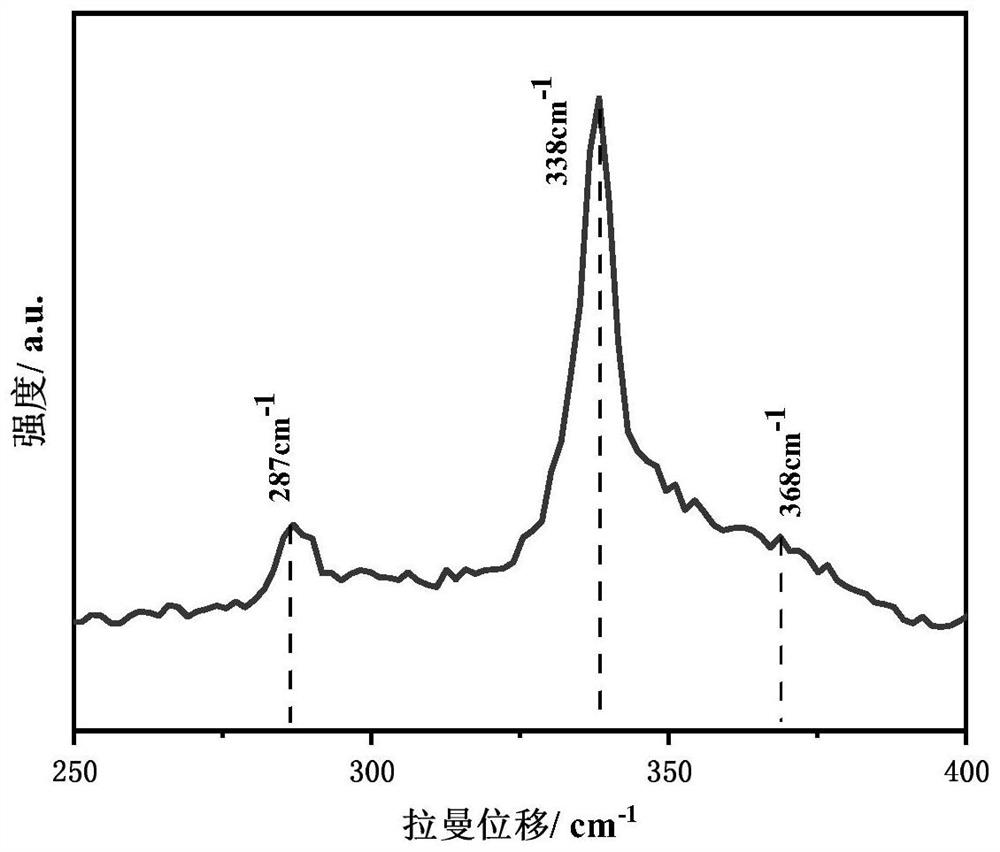

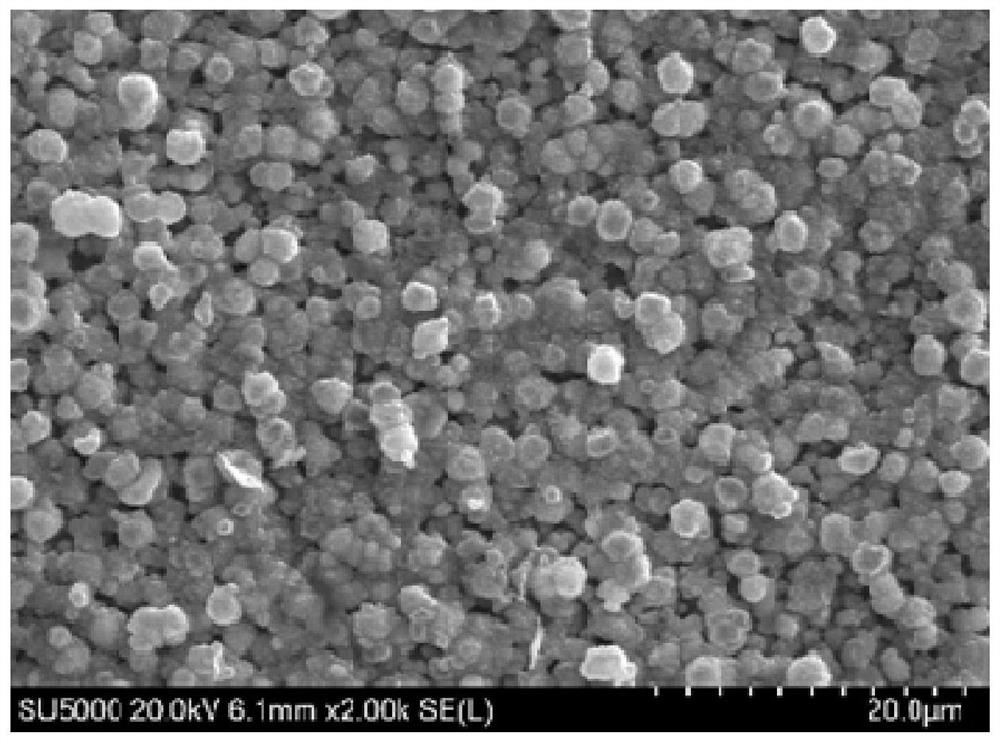

[0036] A method for preparing triple-bandgap chromium-doped copper-zinc-tin-sulfur solar cell thin film materials by electrodeposition, comprising the following steps:

[0037] (1) Use acetone, ethanol and deionized water successively to ultrasonically clean the Mo conductive glass for 15 minutes, and then put the Mo conductive glass in a drying oven for 30 minutes at 80°C in vacuum;

[0038] (2) Add copper chloride, tin chloride and lithium chloride of 0.01mol / L, 0.02mol / L, 0.1mol / L successively in 40ml dehydrated alcohol, adopt single cell electrolyzer, with step (1) The cleaned Mo glass substrate was used as the working electrode, the platinum wire was used as the counter electrode, and the saturated calomel was used as the reference electrode. It was deposited at a constant potential of -1.2V for 30 minutes, and the temperature of the electrodeposition solution was 25°C;

[0039] (3) Add zinc chloride, tin chloride and chromium chloride of 0.04mol / L, 0.01mol / L, 0.004mol / L ...

Embodiment 2

[0051] A method for preparing triple-bandgap chromium-doped copper-zinc-tin-sulfur solar cell thin film materials by electrodeposition, comprising the following steps:

[0052] (1) Use acetone, ethanol and deionized water successively to ultrasonically clean the Mo conductive glass for 15 minutes, and then put the Mo conductive glass in a drying oven for 30 minutes at 80°C in vacuum;

[0053] (2) Add copper chloride, tin chloride and lithium chloride of 0.02mol / L, 0.03mol / L, 0.1mol / L successively in 40ml dehydrated alcohol, adopt single cell electrolyzer, with step (1) The cleaned Mo glass substrate was used as the working electrode, the platinum wire was used as the counter electrode, and the saturated calomel was used as the reference electrode. It was deposited at a constant potential of -1.15V for 30 minutes, and the temperature of the electrodeposition solution was 25°C;

[0054] (3) Add zinc chloride, tin chloride and chromium chloride of 0.04mol / L, 0.01mol / L, 0.004mol / L...

Embodiment 3

[0057] A method for preparing triple-bandgap chromium-doped copper-zinc-tin-sulfur solar cell thin film materials by electrodeposition, comprising the following steps:

[0058](1) Use acetone, ethanol and deionized water successively to ultrasonically clean the Mo conductive glass for 15 minutes, and then put the Mo conductive glass in a drying oven for 30 minutes at 80°C in vacuum;

[0059] (2) Add 0.025mol / L, 0.035mol / L, 0.1mol / L cupric chloride, tin chloride and lithium chloride successively in 40ml dehydrated alcohol, adopt single cell electrolyzer, with step (1) The cleaned Mo glass substrate was used as the working electrode, the platinum wire was used as the counter electrode, and the saturated calomel was used as the reference electrode. It was deposited at a constant potential of -1.15V for 30 minutes, and the temperature of the electrodeposition solution was 25°C;

[0060] (3) Add zinc chloride, tin chloride and chromium chloride of 0.04mol / L, 0.01mol / L, 0.004mol / L s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com