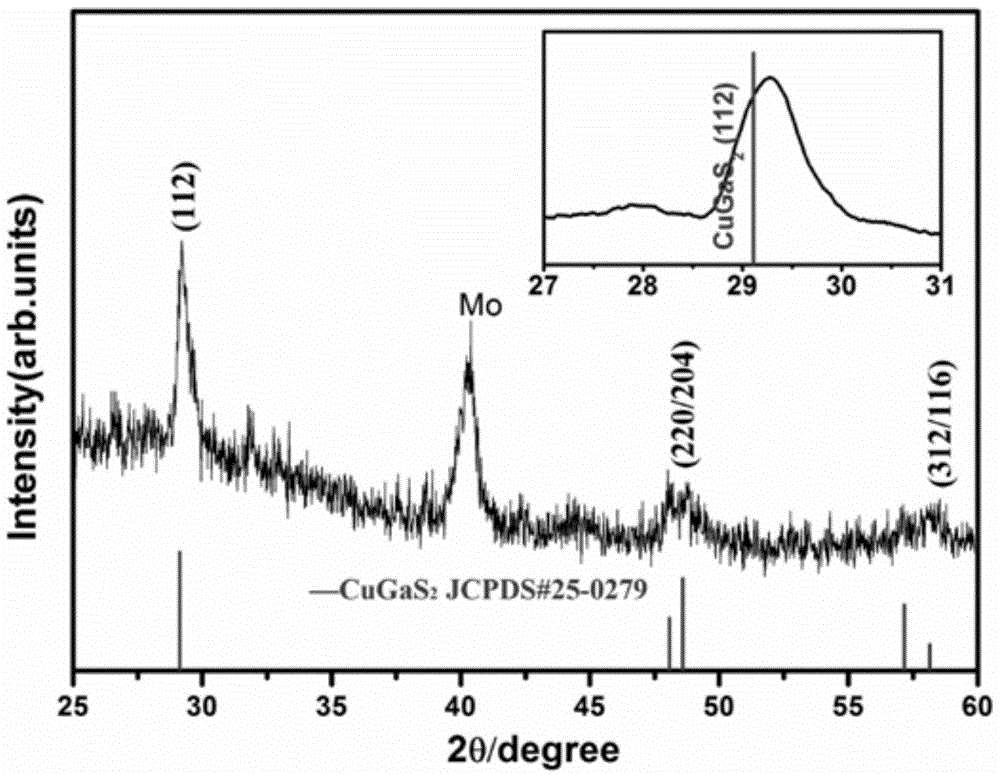

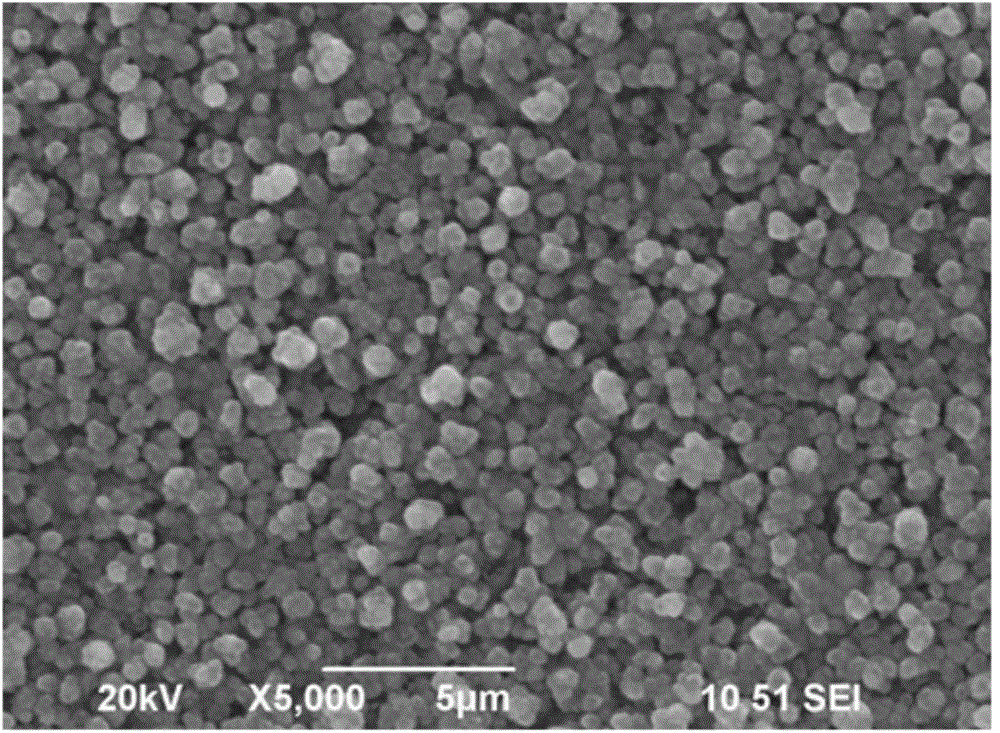

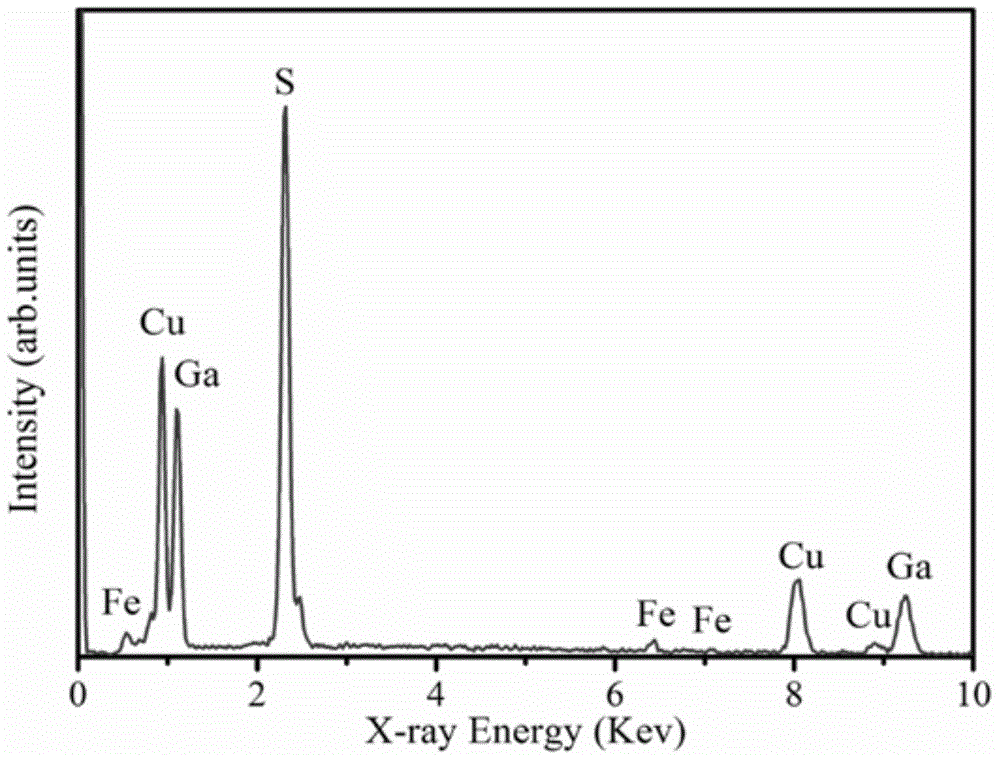

Electro-deposition method for preparing three band gap Fe-doped with copper gallium sulfur solar cell materials

A solar cell and electrodeposition technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of impossible to exceed a single solar cell, high production cost, conversion efficiency constraints, etc., and achieve controllable film composition and crystallization. Good sex, broaden the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a triple-bandgap iron-doped copper-gallium-sulfur thin film material, comprising the following steps:

[0030] (1) Use acetone, ethanol and deionized water successively to ultrasonically clean the Mo conductive glass for 15 minutes, and then place the Mo conductive glass in a drying oven for 30 minutes under vacuum at 80°C.

[0031] (2) Take choline chloride and urea according to the molar ratio of 1:2, stir them evenly, and then dry them in a vacuum oven at 80°C for 12 hours to prepare 40ml of ionic liquid, and add 0.03mol / L and 0.1mol to the solution in turn Copper chloride, gallium chloride and ferric chloride of / L, 0.0005mol / L adopt single-cell electrolyzer, take the Mo glass substrate cleaned in step (1) as working electrode, and platinum wire is counter electrode, saturated Gan Mercury was used as a reference electrode, deposited at a constant potential of -1.2V for 30 minutes, the temperature of the electrodeposition solution was 60° C., a...

Embodiment 2

[0041] A method for preparing a triple-bandgap iron-doped copper-gallium-sulfur thin film material, comprising the following steps:

[0042] (1) Use acetone, ethanol and deionized water successively to ultrasonically clean the Mo conductive glass for 10 minutes, and then put the Mo conductive glass in a drying oven for 30 minutes at 80°C in vacuum.

[0043] (2) Take choline chloride and urea according to the molar ratio of 1:2, stir them evenly, and then dry them in a vacuum oven at 80°C for 8 hours to prepare 40ml of ionic liquid, and add 0.035mol / L and 0.1mol to the solution in turn Copper chloride, gallium chloride and ferric chloride of / L, 0.01mol / L, adopt single cell electrolyzer, with the Mo glass substrate that cleans in the step (1) as working electrode, platinum wire is counter electrode, saturated Gan Mercury was used as a reference electrode, deposited at a constant potential of -1.15V for 20 minutes, the temperature of the electrodeposition solution was 45°C, and ...

Embodiment 3

[0046] A method for preparing a triple-bandgap iron-doped copper-gallium-sulfur thin film material, comprising the following steps:

[0047] (1) Use acetone, ethanol and deionized water successively to ultrasonically clean the Mo conductive glass for 30 minutes, and then place the Mo conductive glass in a drying oven for 30 minutes at 80°C in vacuum.

[0048] (2) Take choline chloride and urea according to the molar ratio of 1:2, mix them evenly, and then dry them in a vacuum oven at 80°C for 14 hours to prepare 40ml of ionic liquid, and add 0.035mol / L and 0.1mol to the solution in turn Copper chloride, gallium chloride and ferric chloride of / L, 0.01mol / L, adopt single cell electrolyzer, with the Mo glass substrate that cleans in the step (1) as working electrode, platinum wire is counter electrode, saturated Gan Mercury was used as a reference electrode, deposited at a constant potential of -1.15V for 20 minutes, the temperature of the electrodeposition solution was 45°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com