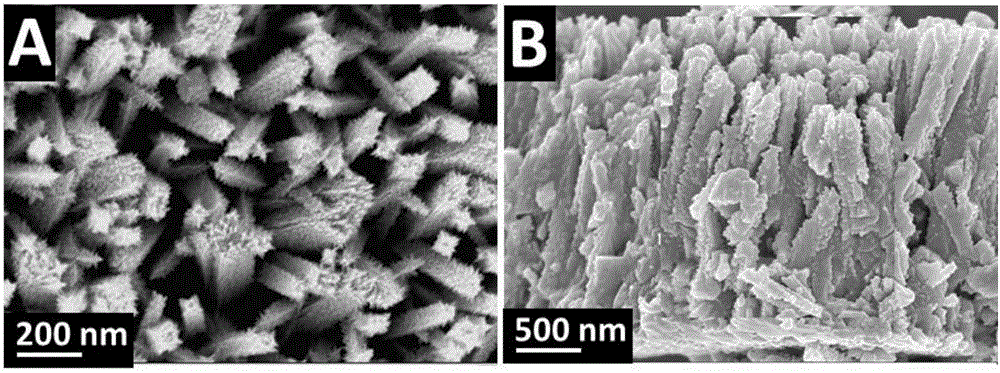

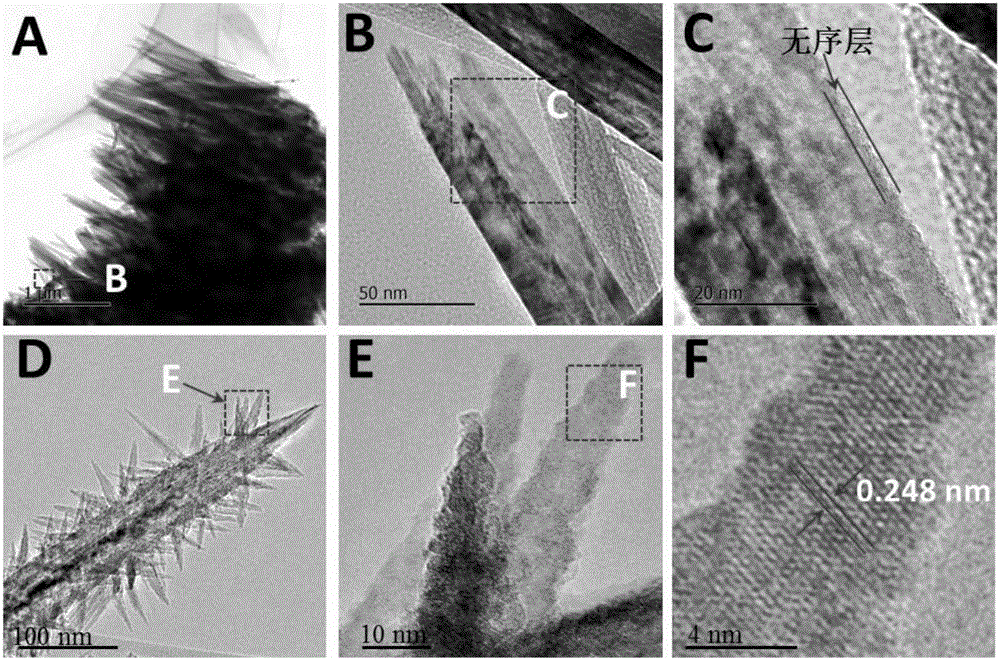

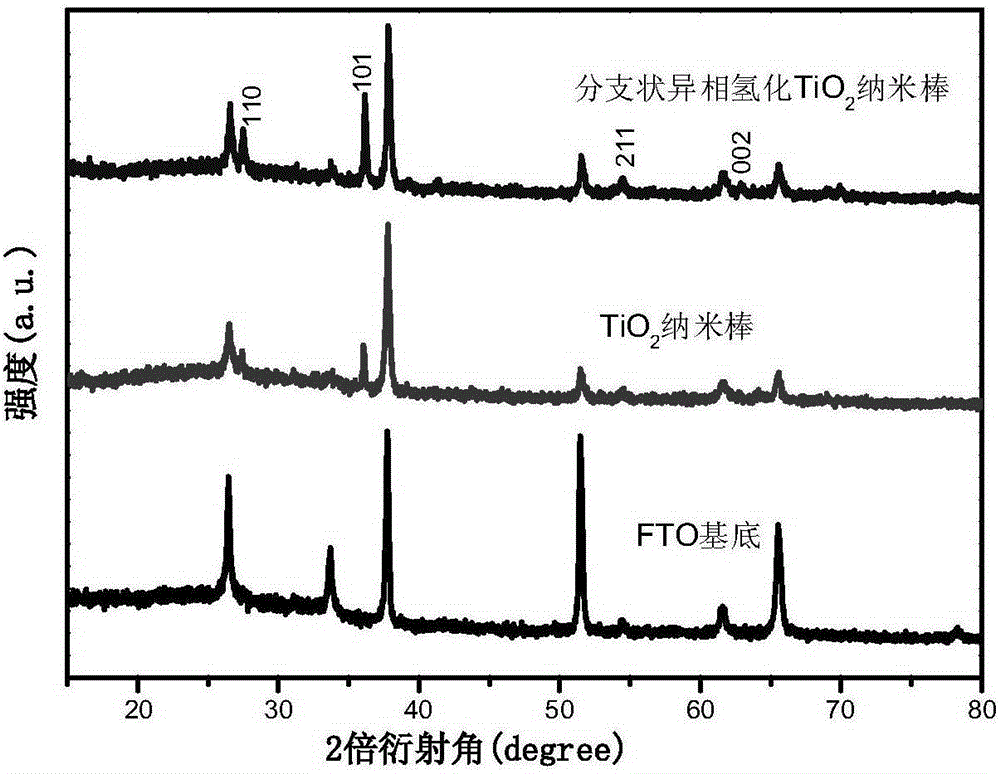

Branched heterogeneous hydrogenated titanium dioxide nanorod array electrode and preparation method thereof

A technology of hydrogenated titanium dioxide and nanorod arrays is applied in the direction of coating, etc., to achieve the effects of less environmental pollution, simple operation steps, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Put the 2cm×5cm FTO conductive glass into acetone, deionized water and ethanol to clean it ultrasonically, and then dry it for later use.

[0030] (2) At room temperature, in a polytetrafluoroethylene lining, mix 50 g of deionized water and 59 g of concentrated hydrochloric acid (36.5 wt%) and stir for 5 minutes, then add 1.2 g of tetrabutyl titanate into the mixed solution and stir for 5 minutes to form The mass ratio is 100:118:2.4 hydrothermal preparation of titanium dioxide nanorod precursor solution. Put 2 cleaned FTO conductive glass pieces into the Teflon lining, put the glass pieces obliquely downward, and the conductive side faces down. After sealing the hydrothermal kettle, put it into an oven to carry out hydrothermal reaction at 170° C. for 6 hours. After the hydrothermal heat is over, turn off the oven, cool to room temperature in the air, take out the FTO conductive glass, wash it with ethanol and deionized water, and obtain the rutile TiO 2 Nanorod ...

Embodiment 2

[0035] (1) Put the 2cm×5cm FTO conductive glass into acetone, deionized water and ethanol to clean it ultrasonically, and then dry it for later use.

[0036] (2) At room temperature, in a polytetrafluoroethylene lining, mix 50 g of deionized water and 60 g of concentrated hydrochloric acid (36.5 wt%) and stir for 5 min, then add 1.5 g of tetrabutyl titanate into the mixed solution and stir for 5 min to form The mass ratio is 100:120:3.0 hydrothermal preparation of titanium dioxide nanorod precursor. Put 2 cleaned FTO conductive glass pieces into the Teflon lining, put the glass pieces obliquely downward, and the conductive side faces down. After sealing the hydrothermal kettle, put it into an oven for hydrothermal reaction, and the reaction temperature was 150° C. for 8 hours. After the hydrothermal heat is over, turn off the oven, cool to room temperature in the air, take out the FTO conductive glass, wash it with ethanol and deionized water, and obtain the rutile TiO 2 Nan...

Embodiment 3

[0041] (1) Put the 2cm×5cm FTO conductive glass into acetone, deionized water and ethanol to clean it ultrasonically, and then dry it for later use.

[0042] (2) At room temperature, in a polytetrafluoroethylene lining, mix 50 g of deionized water and 50 g of concentrated hydrochloric acid (36.5 wt%) and stir for 5 minutes, then add 1.2 g of tetrabutyl titanate into the mixed solution and stir for 5 minutes to form The mass ratio is 100:100:2.4 hydrothermal preparation of titanium dioxide nanorod precursor solution. Put 2 cleaned FTO conductive glass pieces into the Teflon lining, put the glass pieces obliquely downward, and the conductive side faces down. After sealing the hydrothermal kettle, put it into an oven for hydrothermal reaction at 180° C. for 5 hours. After the hydrothermal heat is over, turn off the oven, cool to room temperature in the air, take out the FTO conductive glass, wash it with ethanol and deionized water, and obtain the rutile TiO 2 Nanorod array thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com