Offset worm and wormwheel transmission designing and manufacturing method

A technology of worm gear transmission and manufacturing method, which is applied in the direction of gear tooth manufacturing tools, gear tooth manufacturing devices, worm gears, etc., can solve the problems of poor transmission lubrication effect, inability to control the shape and position of the contact area, etc., and achieve optimal dynamic meshing performance , Absorb installation errors and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

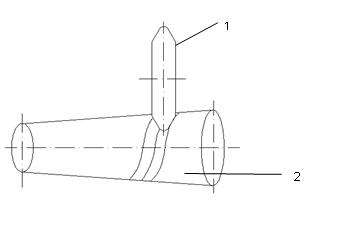

[0025] An embodiment of a design and manufacturing method for offset worm and worm gear transmission. In this method, the worm is processed by forming a disc milling cutter. First, according to the tooth surface equation of the forming disc milling cutter and the actual processing parameters, combined with the design of the worm The principle determines the tooth surface equation of the worm; such as figure 1 As shown, when processing the worm, the angle between the axis of the forming disc milling cutter 1 and the axis of the worm blank 2 is adjusted to the lead angle of the worm, the worm blank 2 remains still, and the forming disc milling cutter 1 moves along the worm Then, according to the tooth surface equation of the worm and the meshing theory of the tooth surface, according to the installation position of the worm wheel and the worm, the tooth surface equation of the worm wheel that is completely conjugate to the worm is obtained.

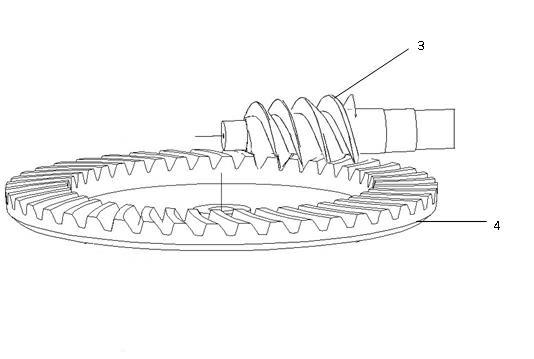

[0026] Such as image 3 Shown is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com