Anti-fretting fatigue protection method for laser shock and coating lubrication composite modification

A technology of laser shock and composite modification, which is applied in coating, laser welding equipment, metal material coating process, etc., can solve the problems of performance interference or conflict of composite modification technology, prolong the germination life, reduce wear and friction Good effect of shear stress and contact surface lubrication state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

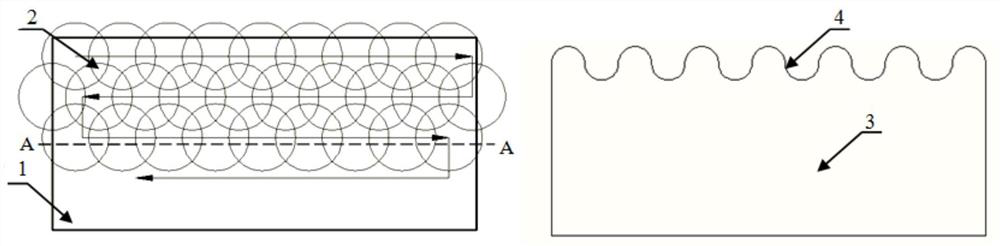

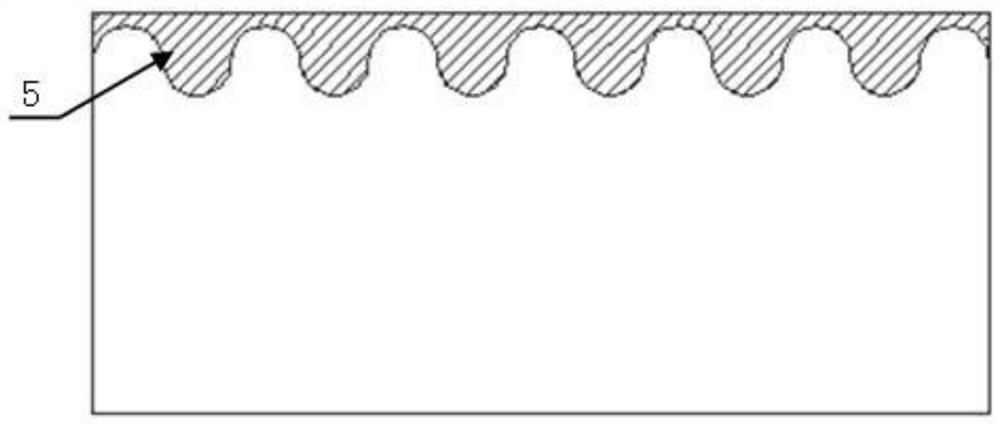

[0028] Such as Figure 1-2 As shown, the present invention provides an anti-fretting fatigue protection method of laser shock and coating lubrication compound modification, which combines laser shock technology and coating lubrication technology, which is a new type of integrated surface protection technology, specifically :

[0029] First, laser shock strengthening technology is used to prepare micro-pit groups (micro-pit texture) in a regular array on the surface of the metal material. The diameter of a single pit is 1-10mm, and the depth of the pit is 1-20μm; then the coating preparation technology is used Apply lubricant to the surface of the dimple.

[0030] Further, the laser shock process is realized according to the laser shock path through a single-spot partial overlapping method, the shape of the light spot is circular or square, and the overlapping rate between the light spots is 10%-50%. Can be greater than 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com