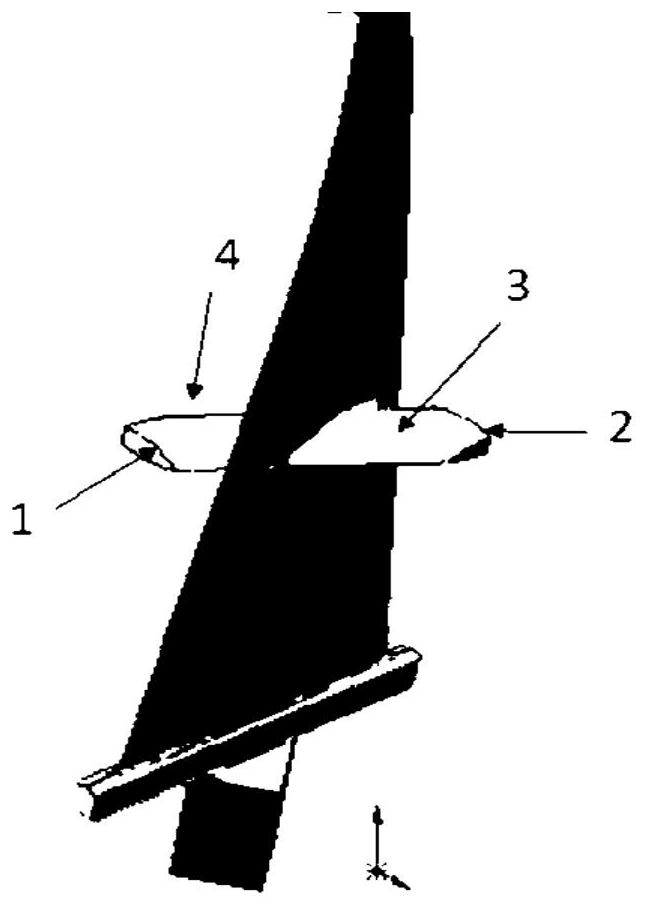

Titanium alloy blade mid-span shroud wear-resistant coating repairing method

A technology of wear-resistant coating and repair method, applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problem of blade repair process and repair method not involved, difficulty in removing residual coating, thin-walled parts Deformation control and other issues to achieve the effect of improving fretting fatigue performance, eliminating the risk of blade torsional deformation, and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Use AC850 passivation glue to protect the non-coated surface of the compressor blade;

[0041] (2) First, the original wear-resistant coating is removed by an electrochemical method, and the concentration of sodium carbonate in the electrochemical solution used is 1.5 mol / L, and the concentration of sodium hydroxide is 0.5 mol / L. Immerse the protected blade shoulder in the electrochemical solution, the temperature of the solution is 60°C, the removal voltage is 6V, and the removal current density is 0.6A / cm 2 , remove after 2 hours and wash and dry.

[0042] (3) The remaining coating is removed by sand blasting, the sand particles are white corundum, the particle size is 150 μm, and the sand blasting pressure is 0.3 MPa.

[0043] (4) The double-layer structure wear-resistant coating is prepared by explosive spraying process. The bottom layer is made of NiCrAl powder with a particle size of 10-40 μm. The thickness of the prepared bottom layer is 75 μm, and the measure...

Embodiment 2

[0050] (1) Use AC850 passivation glue to protect the non-coated surface of the compressor blade;

[0051] (2) First, the original wear-resistant coating is removed by an electrochemical method, and the concentration of sodium carbonate in the electrochemical solution used is 2.0 mol / L, and the concentration of sodium hydroxide is 1.0 mol / L. Immerse the protected blade shoulder in the electrochemical solution, the temperature of the solution is 60°C, the removal voltage is 5.0V, and the removal current density is 1.0A / cm 2 , remove after 2 hours and wash and dry.

[0052] (3) The remaining coating is removed by sand blasting, the sand particles are white corundum, the particle size is 150 μm, and the sand blasting pressure is 0.3 MPa.

[0053] (4) The double-layer structure wear-resistant coating is prepared by explosive spraying process. The bottom layer is made of NiAl powder with a particle size of 10-40 μm. The thickness of the prepared bottom layer is 50 μm, and the measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com