Method of removing oxalate from Bayer-process washing liquid

A Bayer method and lotion technology, applied in the field of oxalate removal, can solve the problems of loss of valuable elements, high cost, and high energy consumption for oxalate removal, and achieve rapid response, compact equipment, and stable removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Sodium oxalate was removed from the Bayer process lotion.

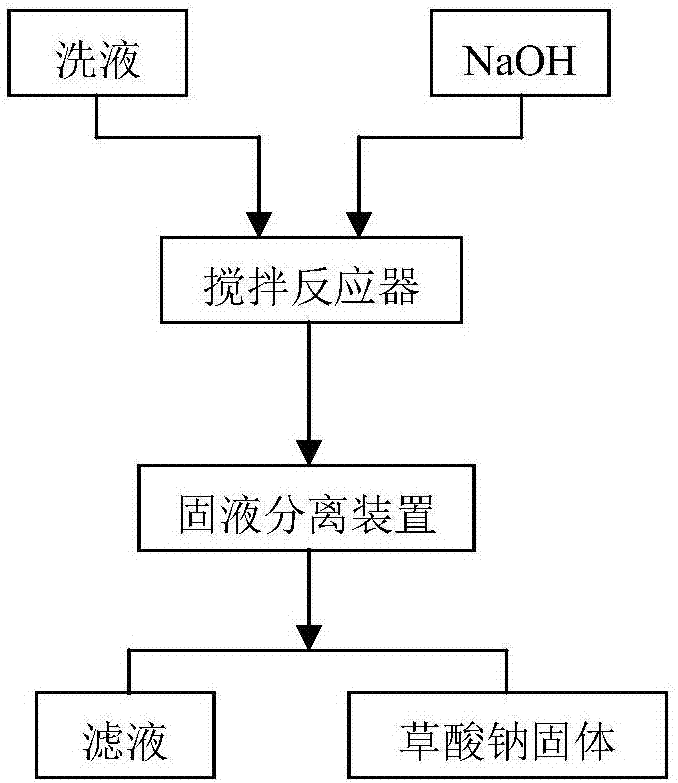

[0024] Such as figure 1 As shown in the flow chart, the C 2 O 4 2- Transfer 500 ml of a sample of Bayer lotion with a concentration of 12 g / L to a 1000 ml stainless steel reactor. The temperature of the lotion itself is about 70 ℃, without heating, prepare a sufficient amount of solid alkali, add it to the lotion, stir and mix. Evenly, make Na 2 O k The concentration is 250 g / L, and the final volume of the reaction system is about 580 ml. The sodium oxalate precipitate was separated by filtration to obtain 8.5 g of solid.

Embodiment 2

[0027] Example 2 The effect of removing sodium oxalate.

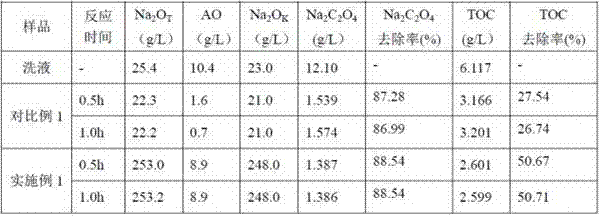

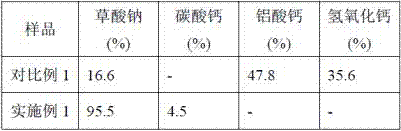

[0028] The reaction solution in the reaction kettle of Example 1 and Comparative Example 1 before the start of the reaction, and the reaction solution after 30 minutes and 60 minutes of reaction was collected from the reaction kettle to determine Na 2 O T , AO, Na 2 O k With Na 2 C 2 O 4 The results are shown in Table 1 below. The results show that although the conventional lime milk removes sodium oxalate, although it can be effectively removed, the valuable element aluminum is almost completely lost; and with the extension of the causticizing time, the oxalate has reverse dissolution. The method of the invention not only can effectively remove sodium oxalate, but also does not occur the phenomenon of oxalate reverse dissolution, and there is no loss of aluminum, which is a valuable element. The solid filter residues obtained in Example 1 and Comparative Example 1 were subjected to XRD analysis, and the analysis results a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com