Concentrated oil feeder for manipulator linear platform

A technology of centralized oil supply and manipulators, which is applied in the directions of manipulators, mechanical equipment, engine lubrication, etc., can solve the problems of reducing the working accuracy of linear platforms, reducing work precision, affecting work efficiency, etc., to improve work efficiency and service life, Guarantee the effect of using precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation methods provided according to the present invention are described in detail below in conjunction with the preferred embodiments.

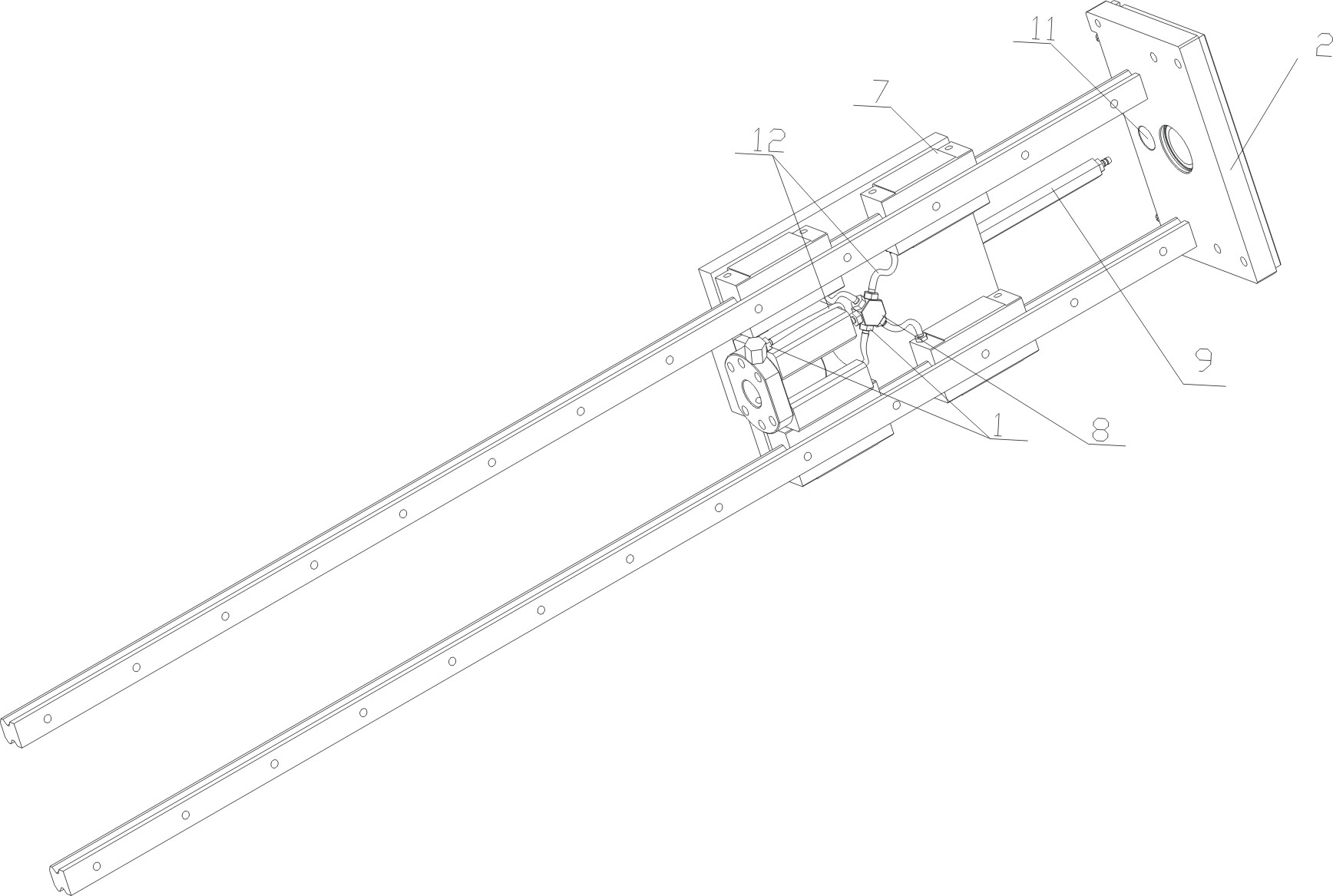

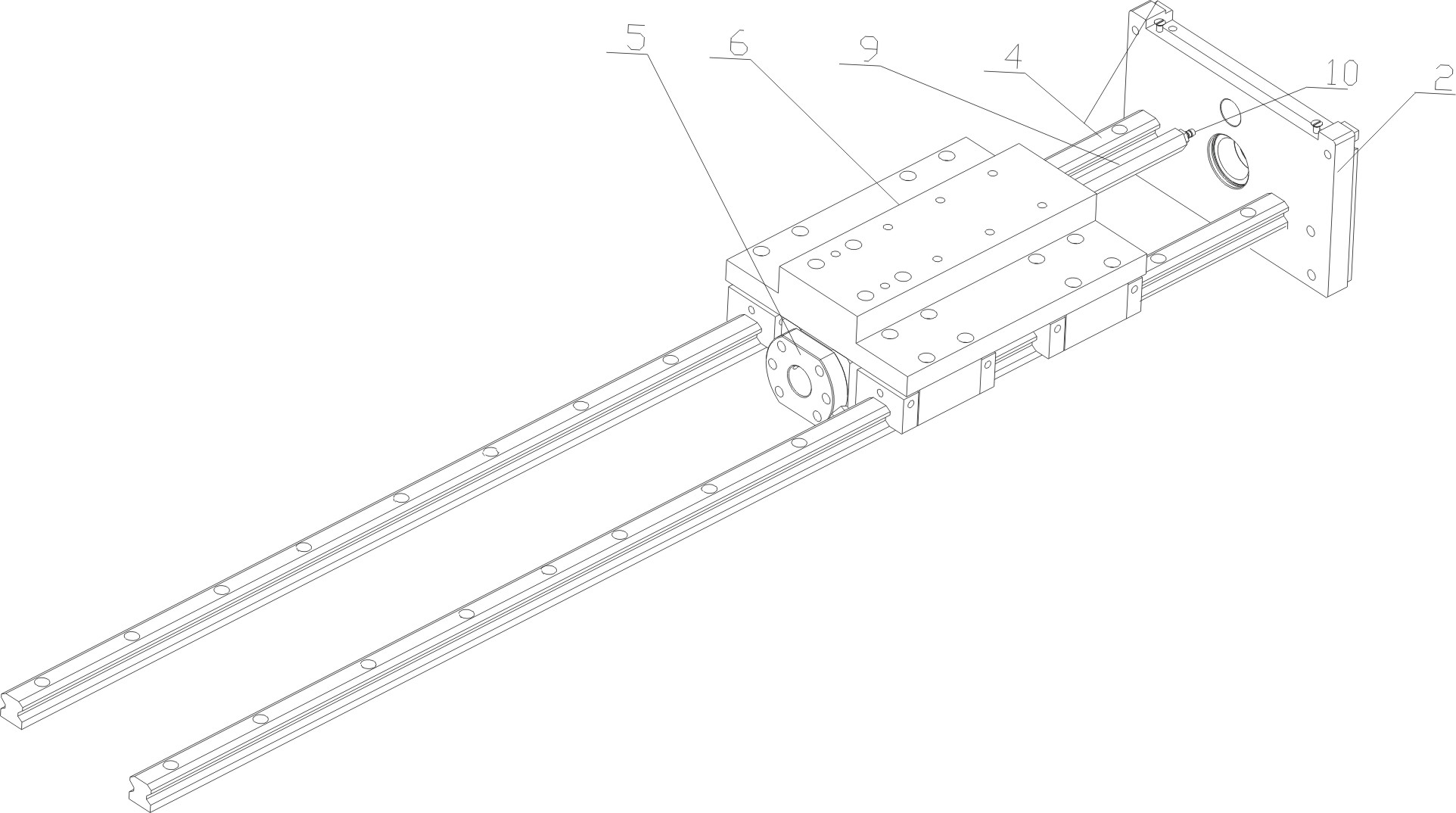

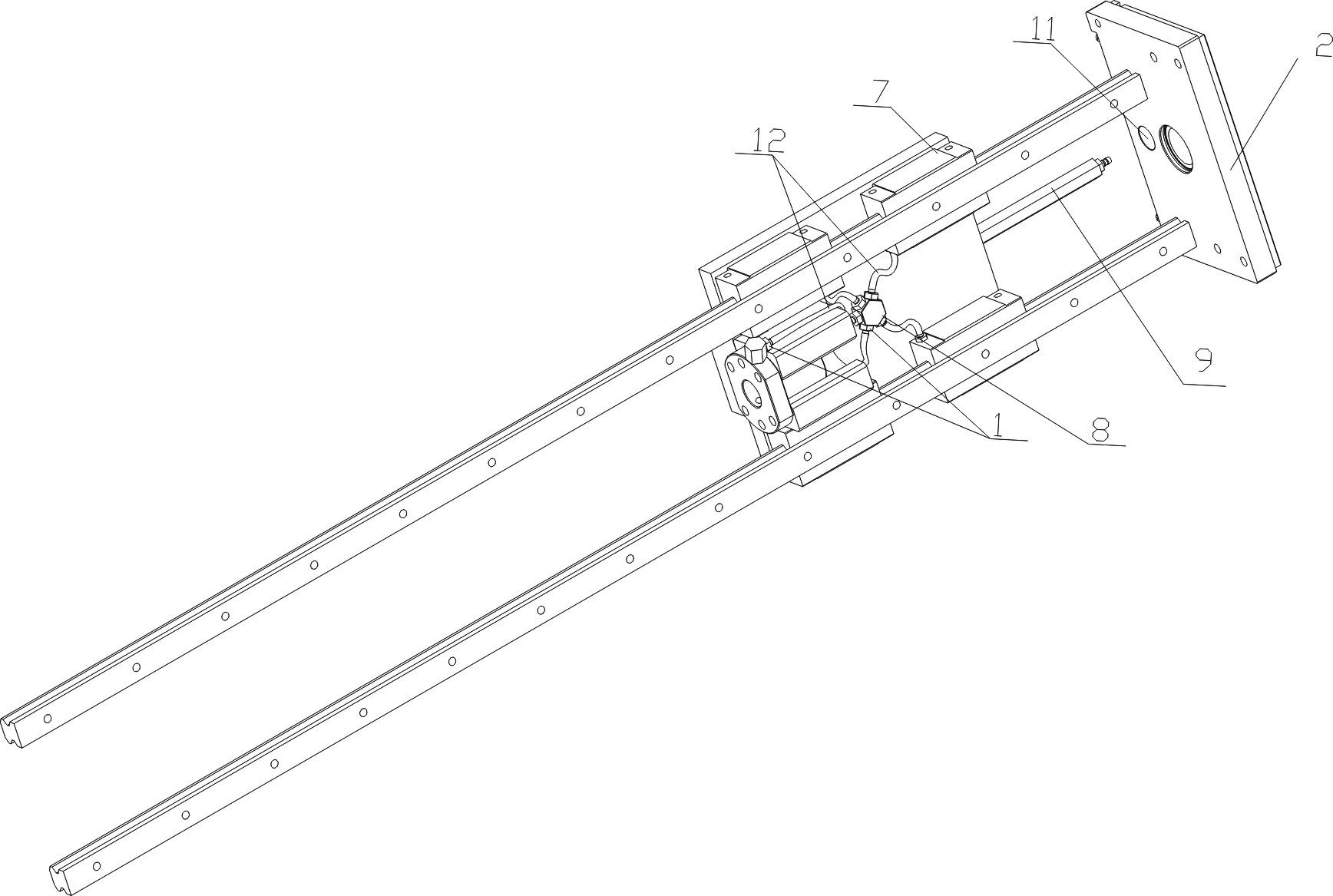

[0011] See the accompanying drawings for details, a centralized oil supply device for a manipulator linear platform, including a base (not shown in the figure), a dustproof plate 2, fixing seats (not shown in the figure) and support seats 3 respectively placed at both ends of the base, linear Guide rail 4, ball screw (not shown in the figure), the front end support seat of the base supports the front end shaft head of the ball screw of the transmission mechanism, and the nut head 5 screwed with the ball screw passes through four sliders fixed on the connecting plate 6 7 connection, the four sliders are slidingly connected with the linear guide rail 4 respectively, the oil collector 8 is fixedly connected to the lower part of the connecting plate, the oil collector is placed at the center of the four sliders, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com