Patents

Literature

31results about How to "Convenient oil supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

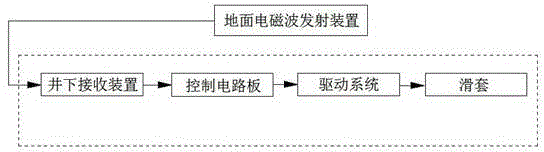

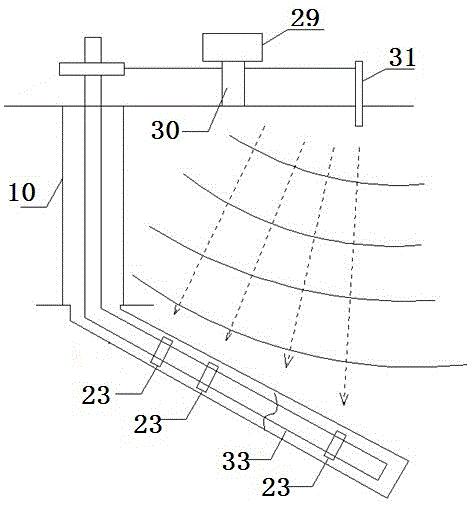

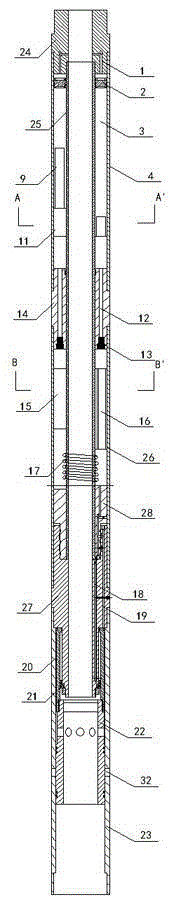

Ground control method for underground sliding sleeves

ActiveCN104088602AReal-time control switch actionEasy to operateFluid removalWell/borehole valve arrangementsInput controlControl theory

The invention discloses a ground control method for underground sliding sleeves. The ground control method comprises the steps as follows: a ground electromagnetic wave emitting device generates command information for controlling opening or closing of a plurality of underground sliding sleeves according to input control commands, and the command information is sent to the underground sliding sleeves after amplification; an electromagnetic wave receiving device arranged in each underground sliding sleeve receives the command information sent from the ground, and the command information is compared with respective pre-assigned control commands; if the command information is not consistent with the assigned control commands of the underground sliding sleeves, the underground sliding sleeves which are not consistent with the command information do not act and continuously wait for next ground command information; and if the command information is consistent with the assigned control command of one underground sliding sleeve, the underground sliding sleeve acts and finishes opening or closing operation required by the command information. According to the ground control method for the underground sliding sleeves, opening and closing actions of the underground sliding sleeves can be remotely controlled by the ground electromagnetic wave signals and can be controlled in real time, and further, ball pitching is not required.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

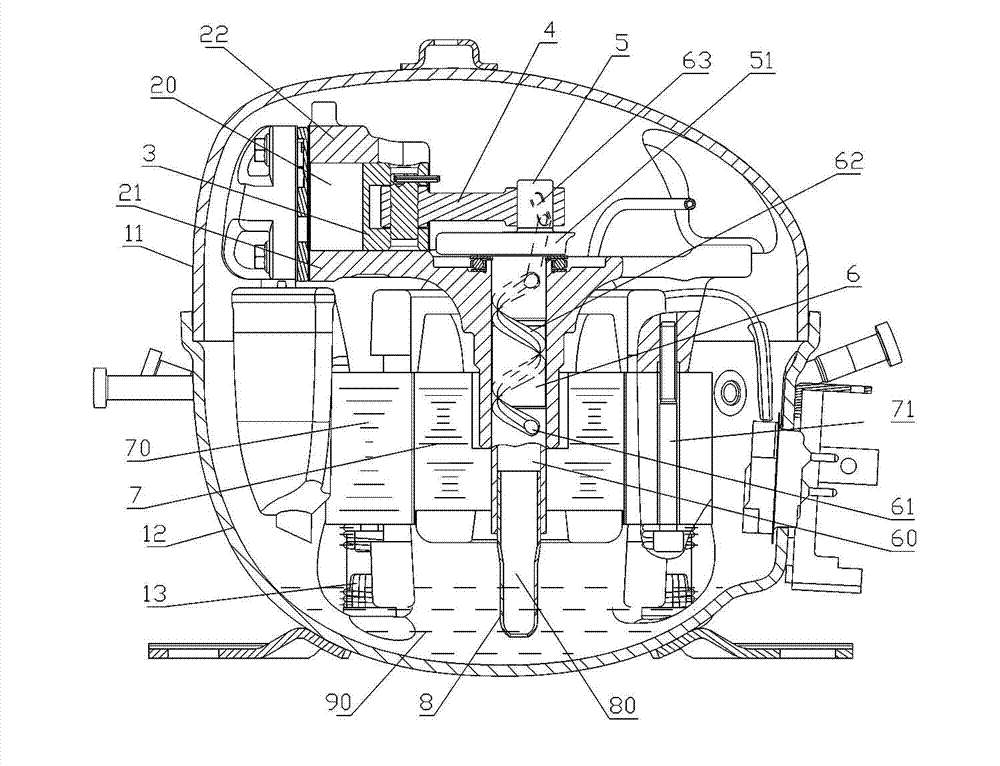

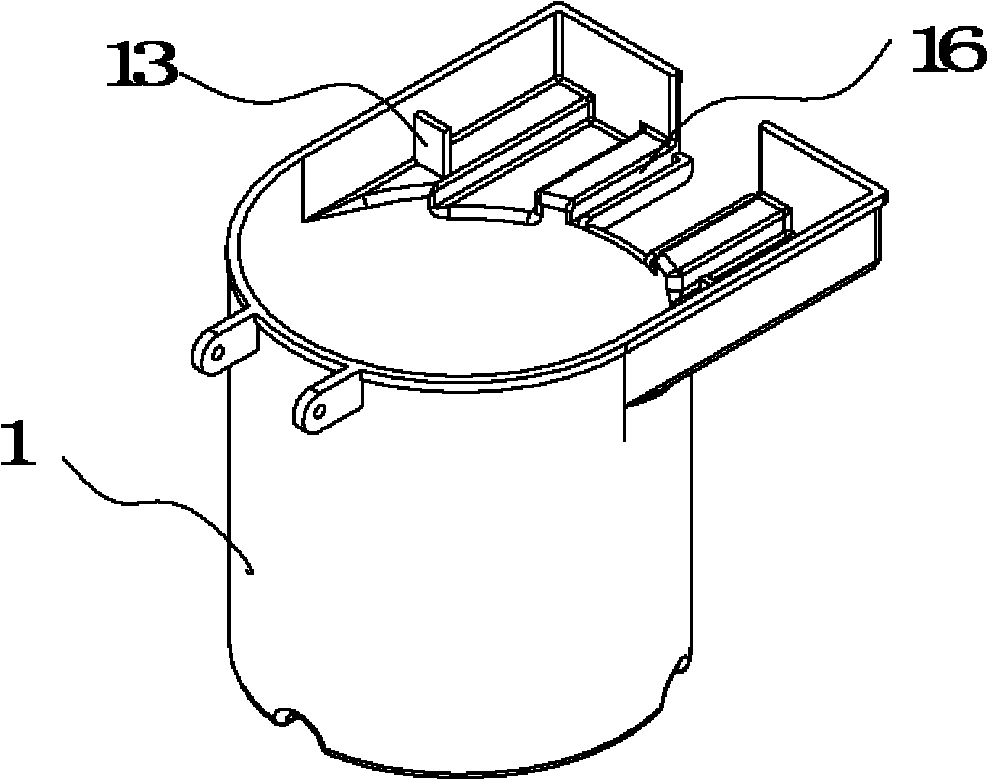

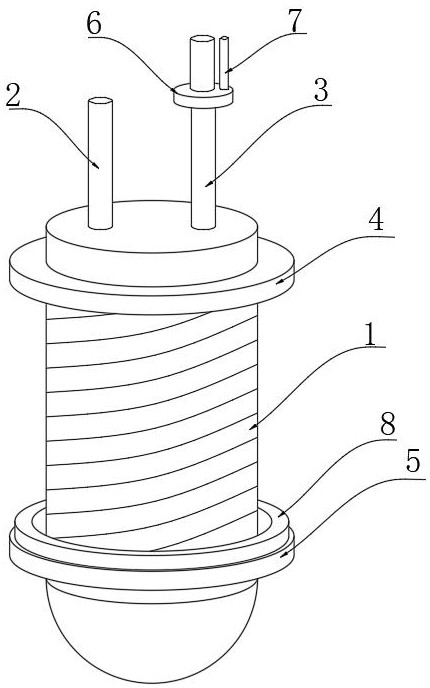

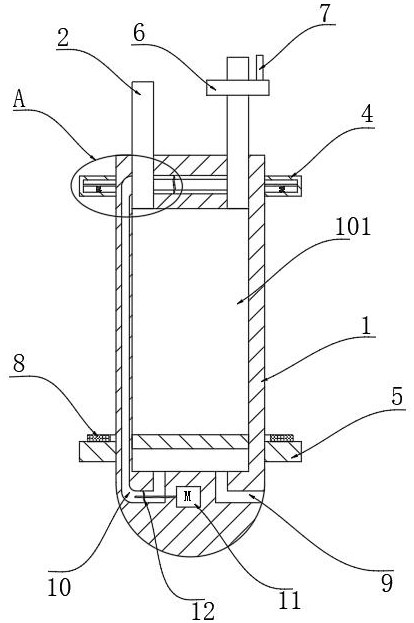

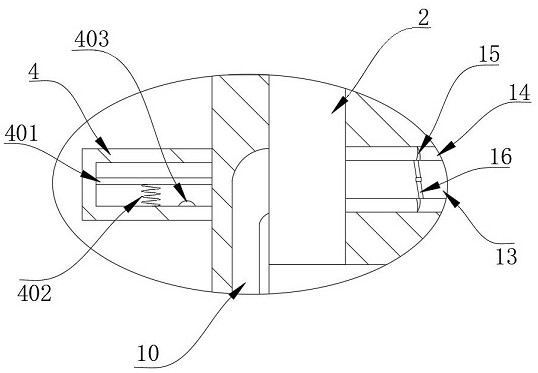

Refrigerator compressor with filter

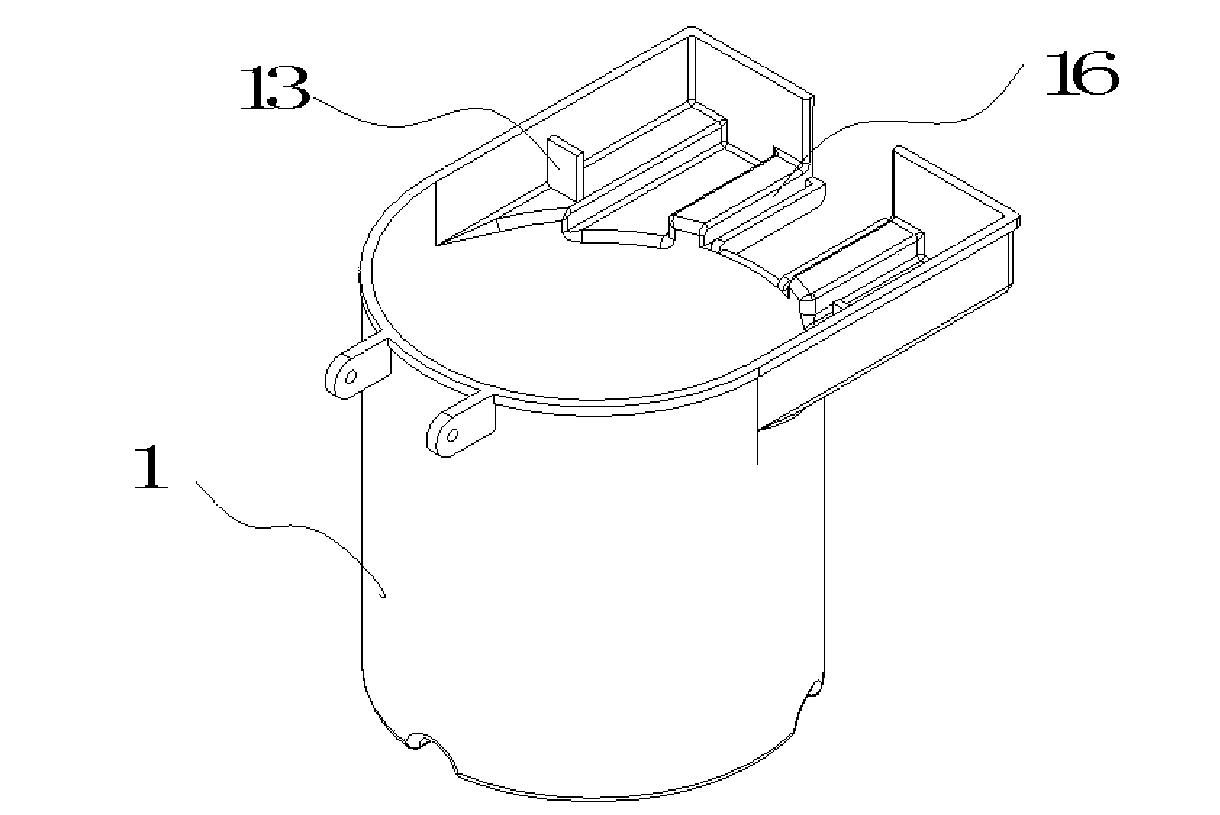

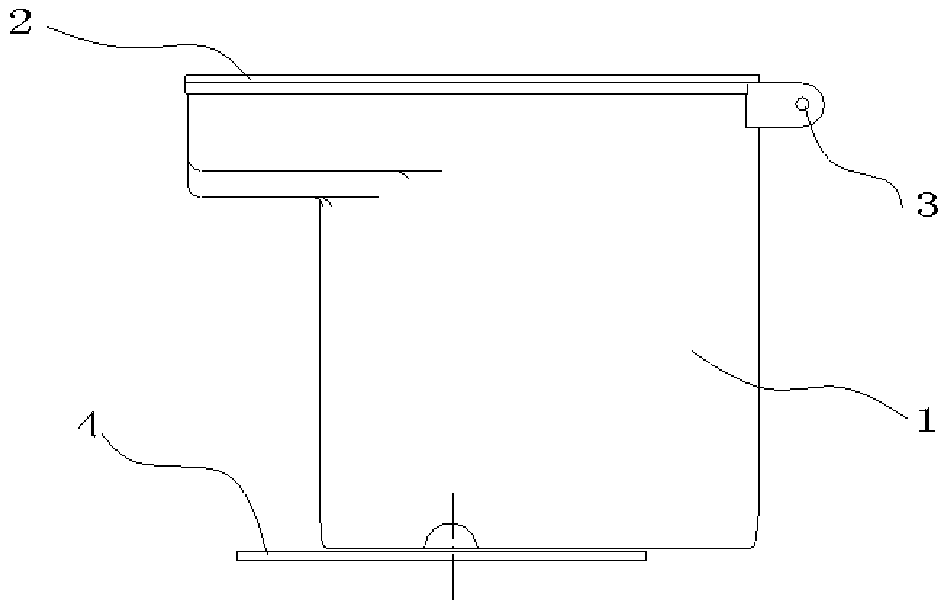

InactiveCN102953957AUnexpected technical effectAvoid damagePositive displacement pump componentsPiston pumpsRefrigeration compressorFixed frame

The invention provides a refrigerator compressor with a filter, which comprises a housing, a core and a core support structure, wherein the core comprises a support, a cylinder body, a crank shaft, a motor stator and a motor rotor, the cylinder body is connected with the support, the core is installed in the housing through the core support structure, and an oil sump is arranged below the core; the crank shaft comprises a crank shaft part, a balance part and a main shaft part, and the crank shaft is provided with an oil supply channel which comprises an upper oil hole, an outer oil groove, a middle oil hole and an oil suction cavity; an oil suction pipe is connected with the lower end of the crank shaft, the filter which comprises an upper ring plate, a filter screen and a fixed frame is arranged in the oil sump, and the filter is connected with a lower housing through supporting legs so that the end of the oil suction pipe penetrates through the opening of the filter screen and extends into the filter screen. The refrigerator compressor with the filter has the characteristics that lubricating oil supplied to links, pistons and other moving parts from the oil suction pipe is filtered, which can greatly reduce damage of solid impurities in the lubricating oil to the moving parts and is favorable to prolonging the service life of the refrigerator compressor; the refrigerator compressor with the filter has a simple structure, can be installed easily and has good using effects.

Owner:WANBAO GROUP COMPRESSOR CO LTD

Elevator guide rail oilcan

The invention relates to a lubricating technology of an elevator guide rail, in particular to an elevator guide rail oilcan which has lightness, flexible installation and convenient oiling. The elevator guide rail oilcan comprises an oilcan body and an oil can cover and is characterized in that the upper end of the oilcan body is designed into a '7'-shaped bulge; the middle part of the bulge is provided with an elevator guide rail containing cavity which has the same shape as the section of the elevator guide rail; the two ring surfaces of the bulge are provided with oil-supplying grooves; oil-returning grooves are arranged below the two side edges of the elevator guide rail containing cavity; the upper part of the oilcan body is provided with the oilcan cover; an oil absorbing device is arranged above the oil-supplying groove which is tightly attached with the bulge; the oil absorbing device absorbs lubricating oil in the oilcan body to the position of the elevator guide rail containing cavity; and an oil absorbing belt arranged on the oil absorbing device is used for oiling and lubricating on the elevator guide rail. The oilcan is fixed on an elevator cab guide shoe; a cotton-strip oil absorbing belt in an elevator guide rail notch is contacted with the elevator guide rail; and when the elevator cab runs, the oil absorbing belt oils the lubricating oil on the guide rail continuously and automatically.

Owner:周伟立

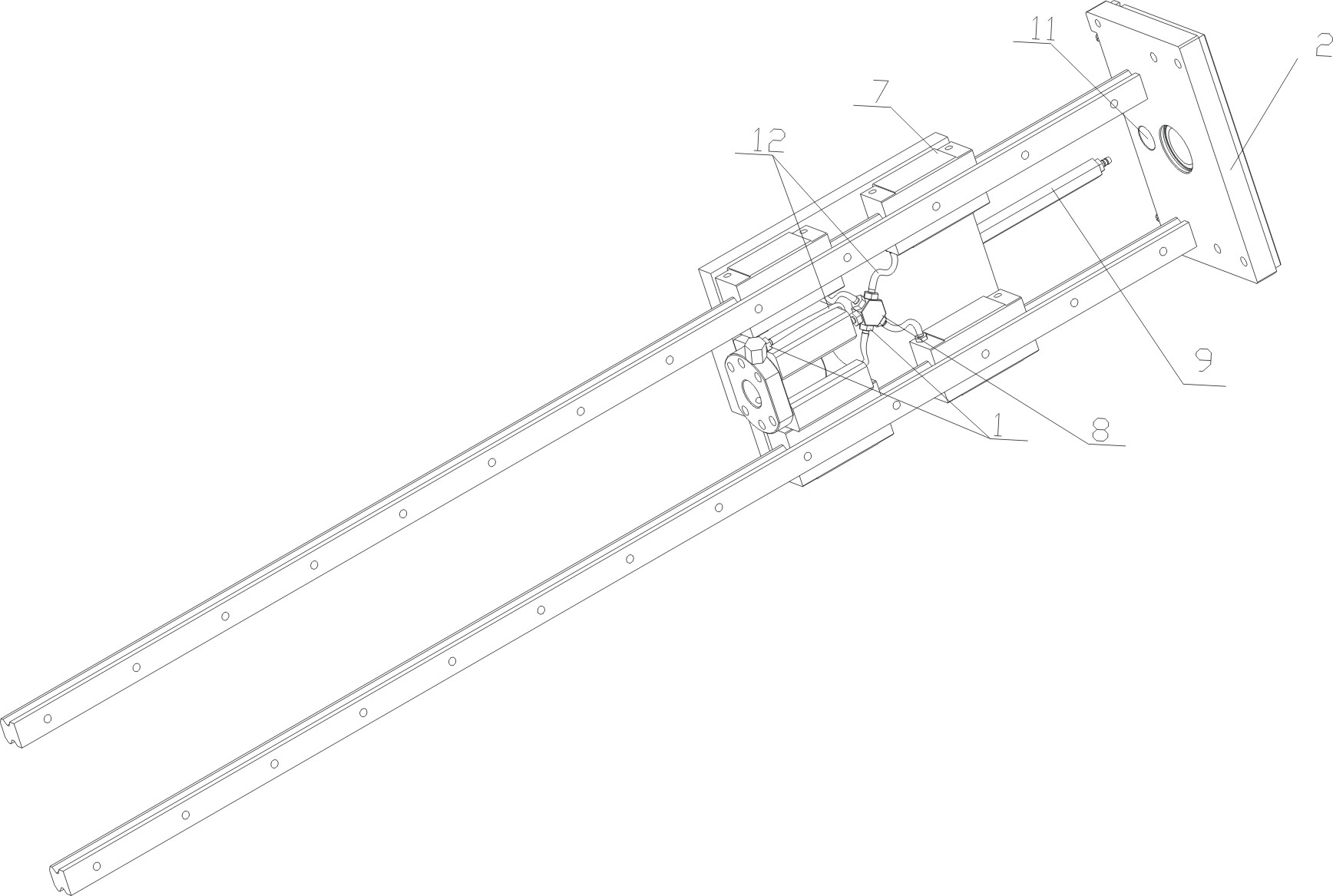

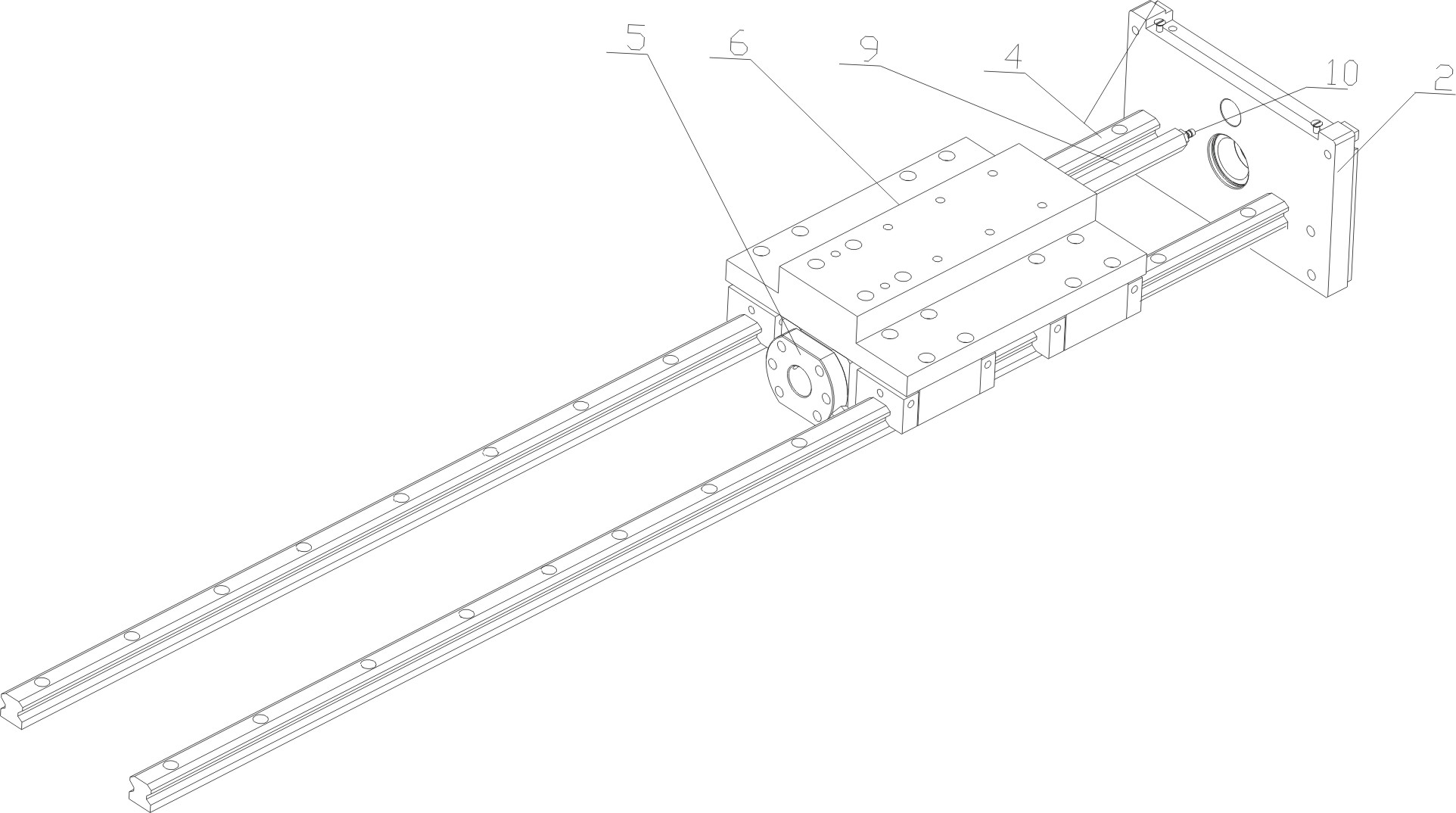

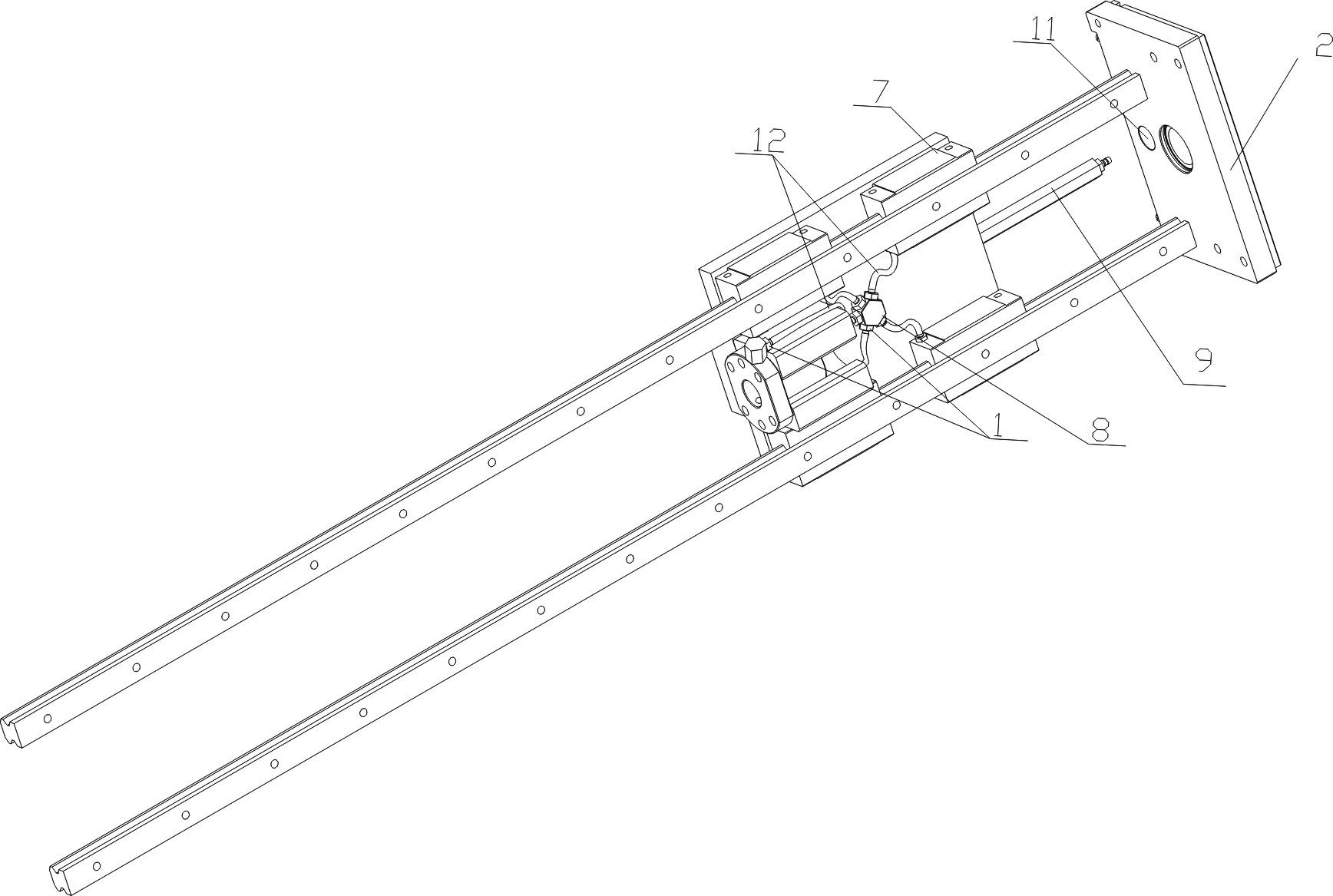

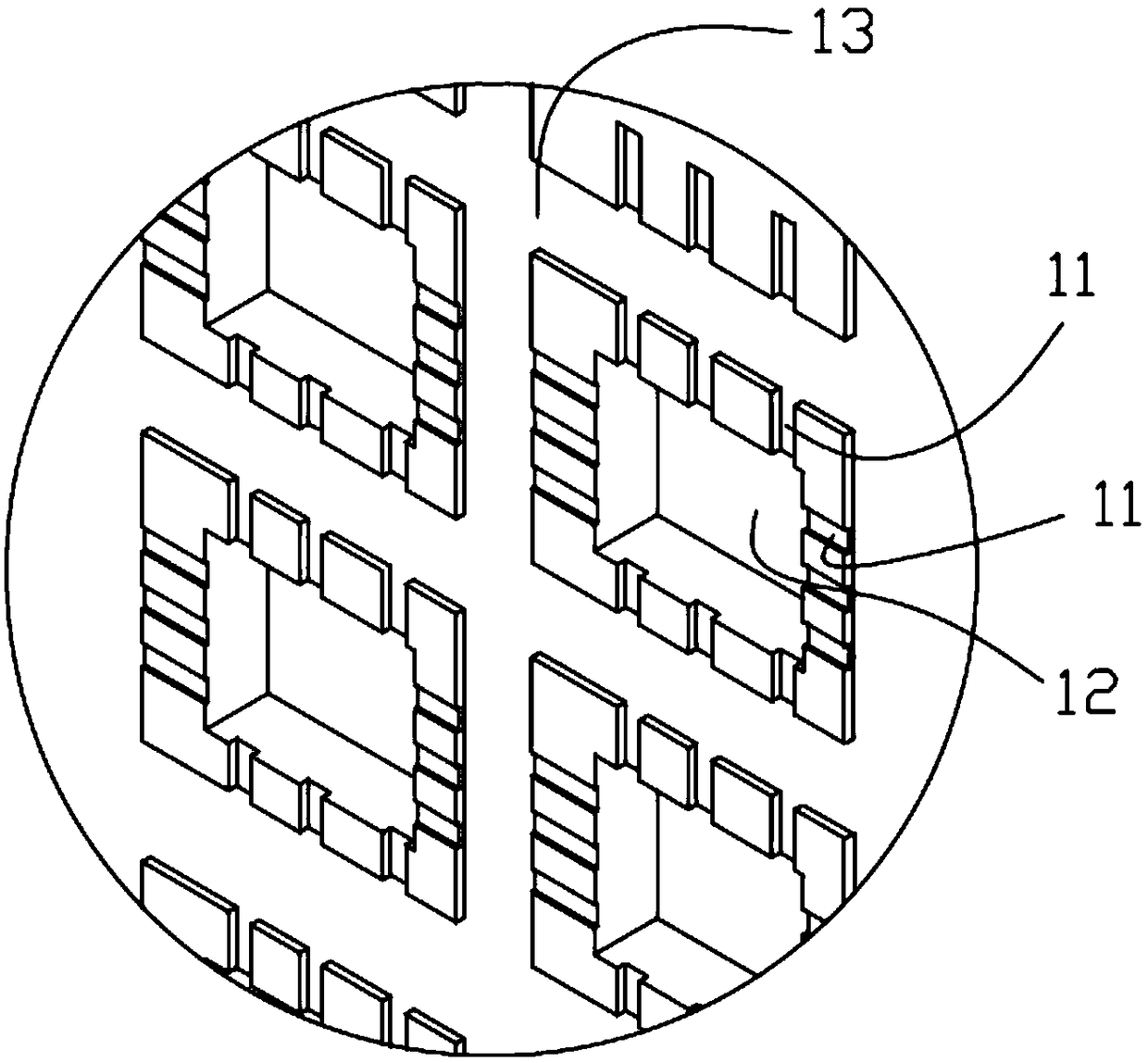

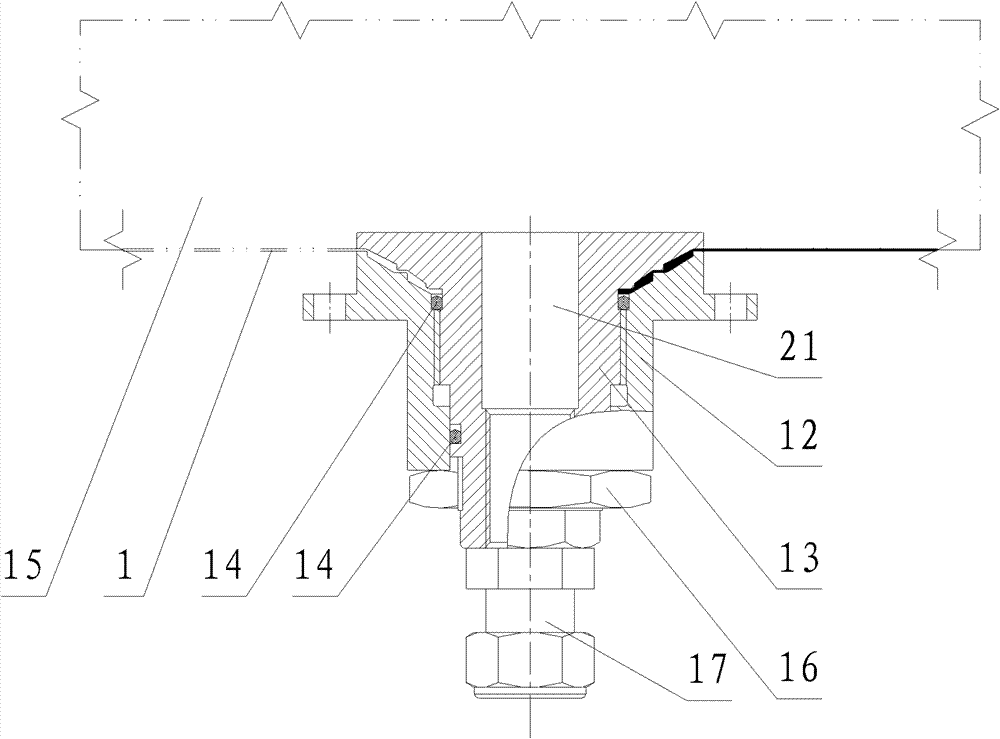

Concentrated oil feeder for manipulator linear platform

InactiveCN101804641AGuaranteed accuracyImprove lubrication statusManipulatorEngine lubricationBall screwManipulator

The invention relates to a concentrated oil feeder for a manipulator linear platform, which comprises a base, a dust-proof plate, a fixed seat, a supporting seat, a linear guide rail and a ball screw, wherein the fixed seat and the supporting seat are respectively arranged on both ends of the base; the supporting seat arranged at the front end of the base supports the front end spindle nose of the ball screw of a transmission mechanism; a nut head screwed with the ball screw is connected with a slide block fixed on a connecting plate; and the slide block and the linear guide rail form a sliding joint. The concentrated oil feeder is characterized in that the lower part of the connecting plate is fixedly provided with an oil catcher, the oil inlet end of the oil catcher is communicated with an oil inlet pipe through an oil passage on the connecting plate, the oil catcher is provided with a plurality of oil outlet ends, and the oil outlet ends are communicated with the slide block and the nut head through oil pipes and flow nipples. When injecting oil to the platform or one machine in the platform combination, the operator can inject oil only after opening the dust cap without affecting the original usage precision of the sliding way, therefore, the invention has the advantages of concentrated oil feeding and simple operation, and can properly increase the number of oil feeding so that the platform is in a favorable lubrication state all along.

Owner:天津市中马骏腾精密机械制造有限公司

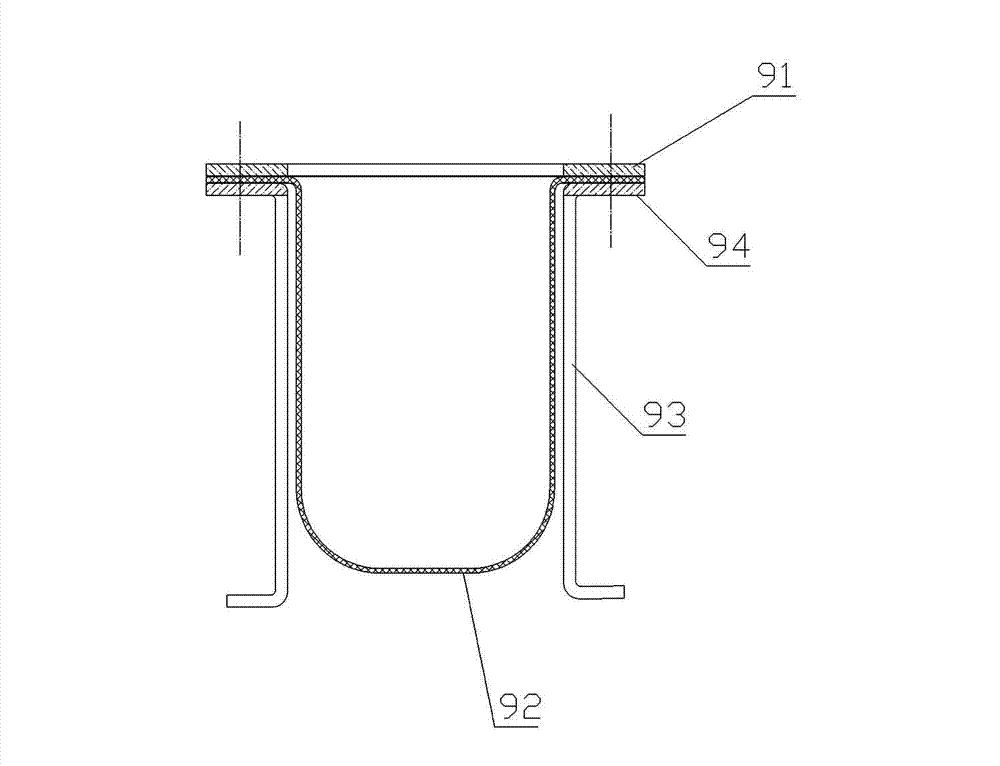

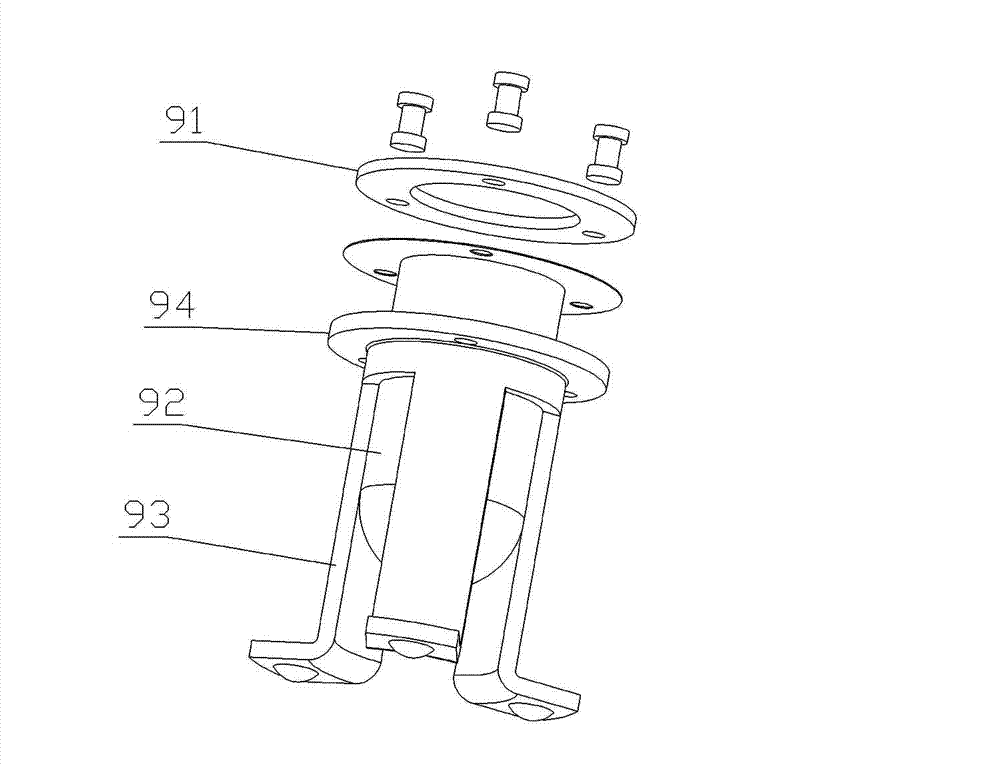

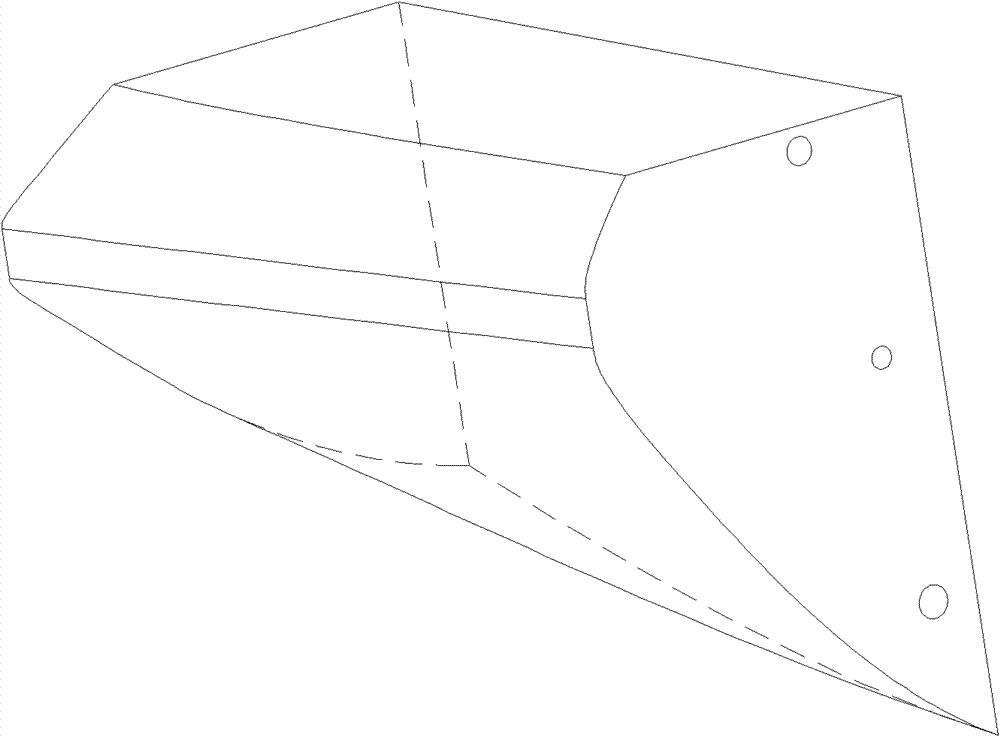

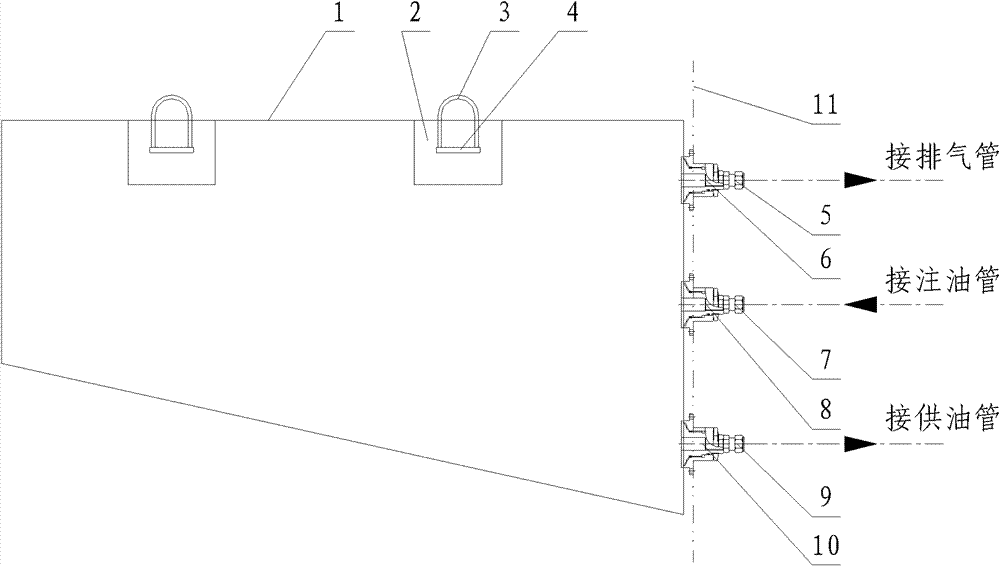

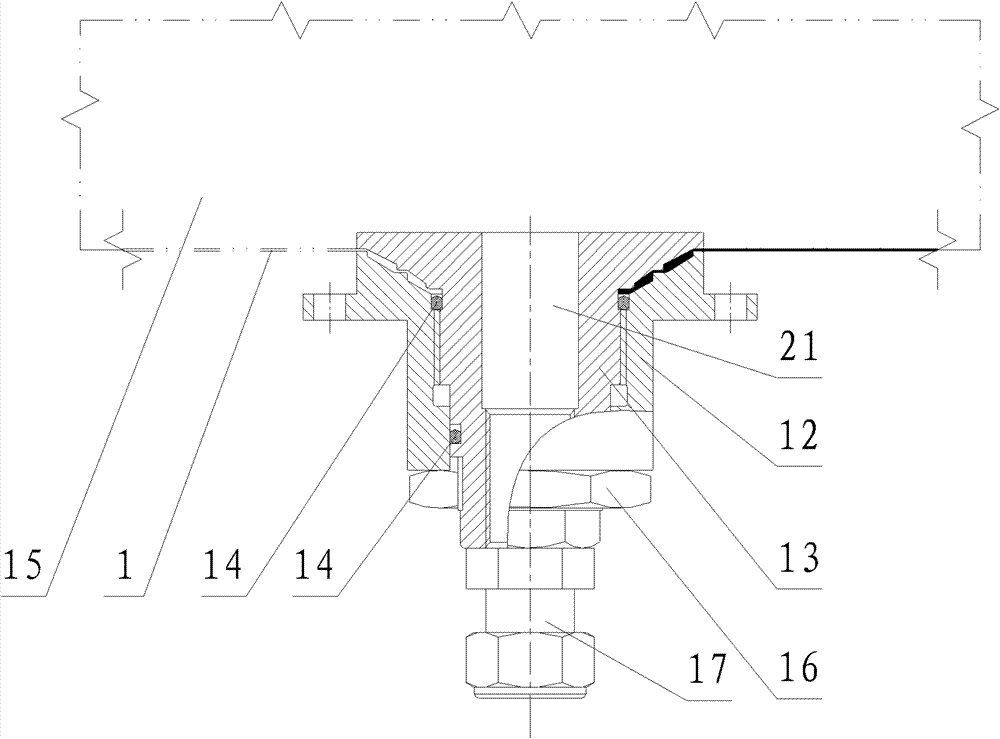

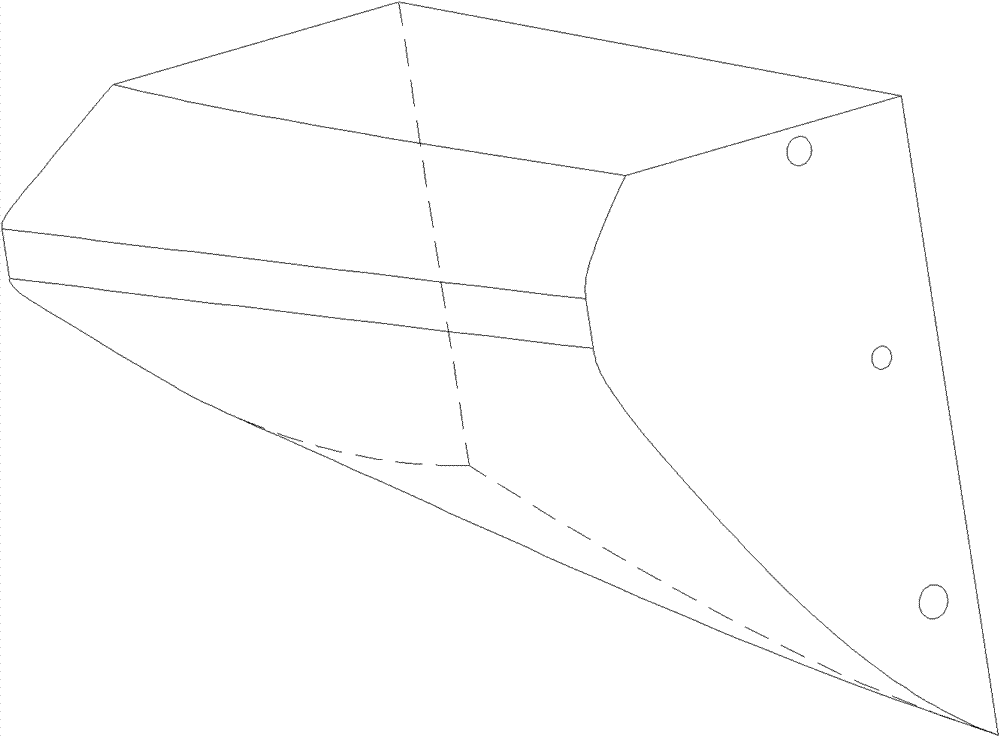

Soft oil bag of underwater vehicle

InactiveCN102951277AImprove maneuverabilityHigh strengthUnderwater vesselsUnderwater equipmentInjection portFuel tank

The invention relates to a soft oil storage device applied in an underwater vehicle, and particularly relates to a soft oil bag of an underwater vehicle. A bag wall is made of a polyurethane material. The bag wall is fixed on the wall of a cabin of the underwater vehicle by three sealed oil nozzle bolts to ensure the sealing of the wall of the cabin, and is fixed in the oil cabin by a plurality of hangers arranged on bag wall hanger holders. The ideal original state of the oil bag is the vacuum state, the bag walls are pasted together, and fuel oil is injected to the oil bag by an oil injection pump through an oil injection pipe and a sealing oil nozzle at an oil injection port. Along with the injection of the fuel oil, the oil bag is gradually filled. If the oil bag is initially provided with a certain amount of air, the air is exhausted by a sealing oil nozzle at an air exhaust port and an air exhaust pipe along with the injection of the fuel oil. When the fuel oil is required to be used, the fuel oil enters into a daily fuel oil tank through a sealing oil nozzle at an oil supply port and an oil supply pipe. The air bag is gradually shriveled along with the consumption of the fuel oil, and water is replenished into the cabin at any time, so that the function of not changing weight and gravity center parameters along with the fuel consumption of the underwater vehicle can be realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

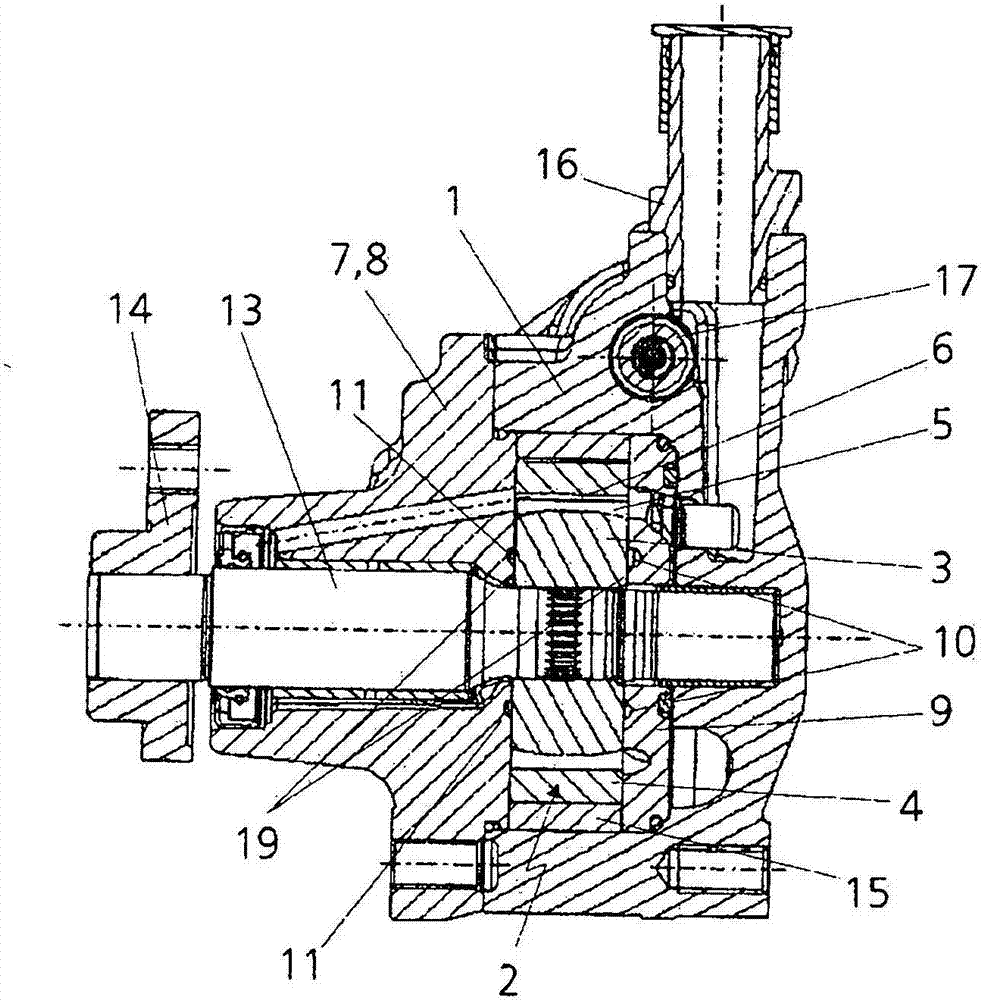

Contact device for cone ring transmission

InactiveCN101131200ASmall pressing forceConvenient oil supplyGearing controlFriction gearingsEngineeringMechanical press

Owner:GETRAG FORD TRANSMISSIONS GMBH

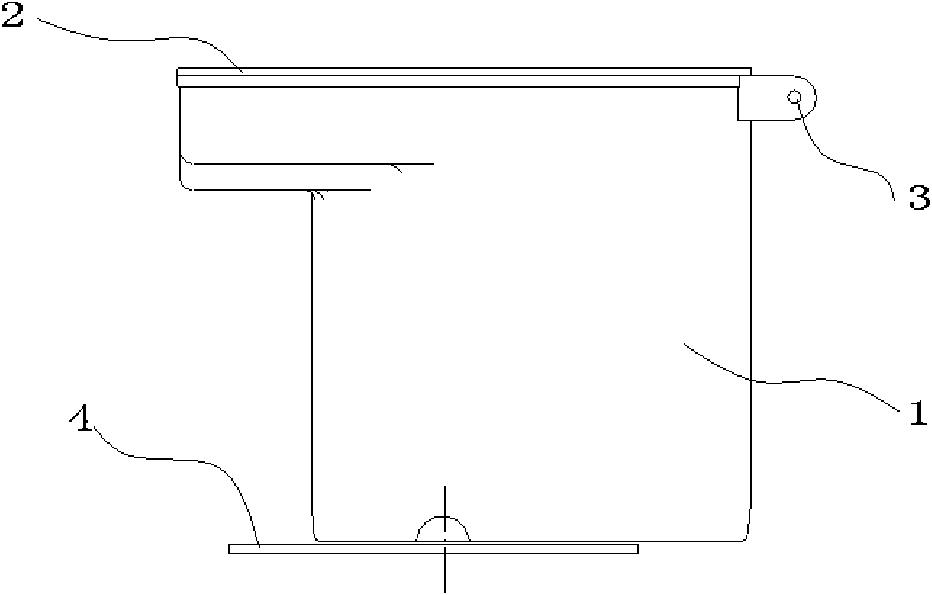

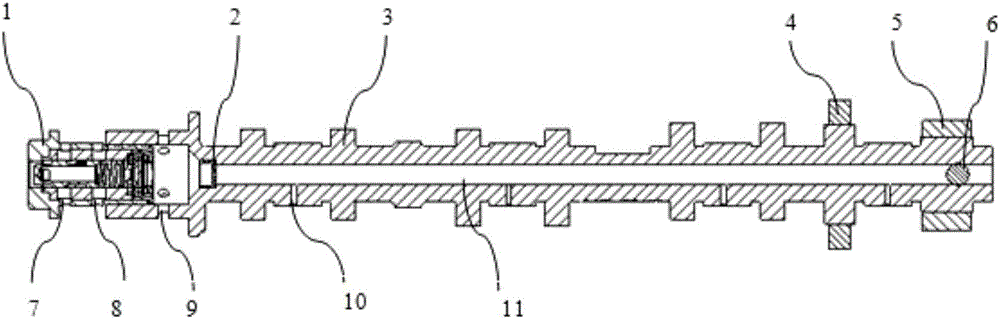

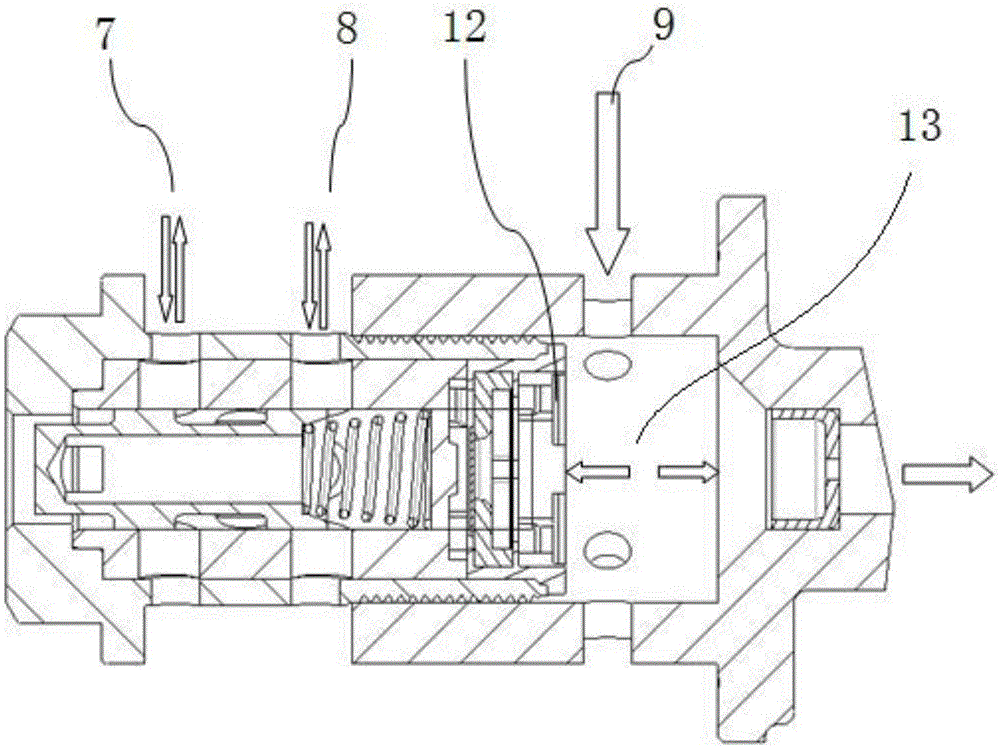

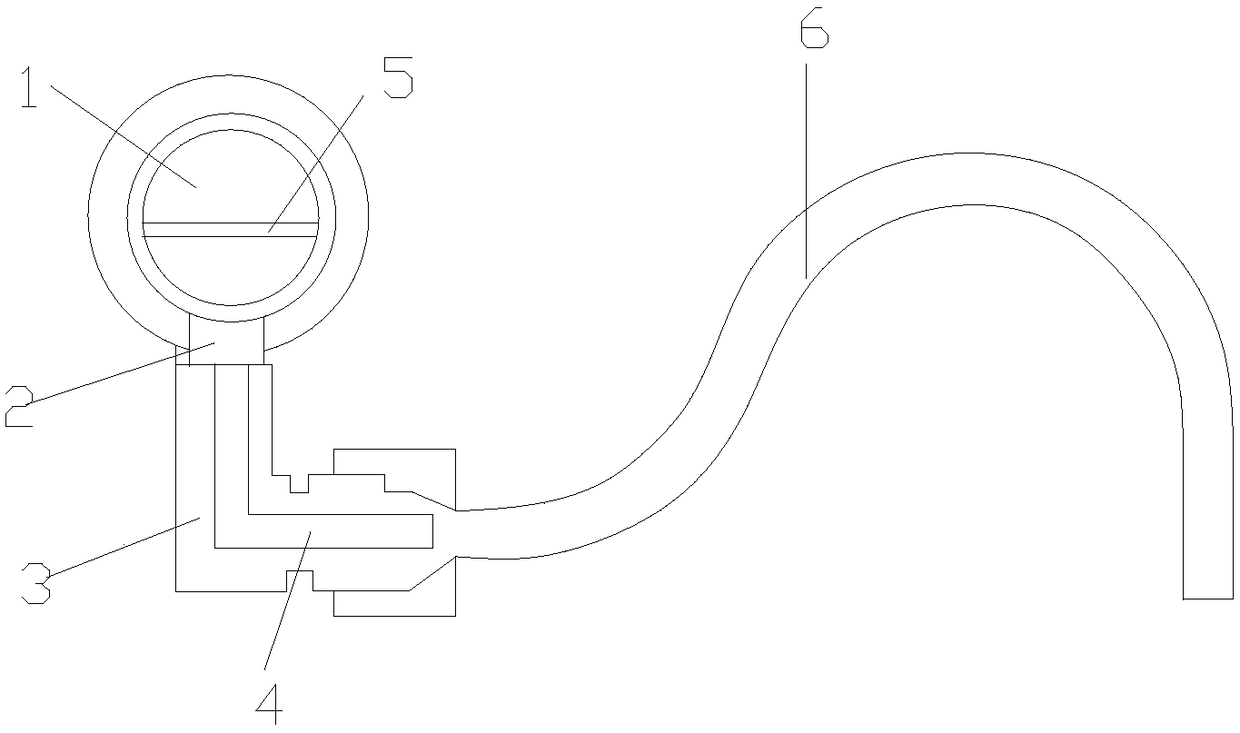

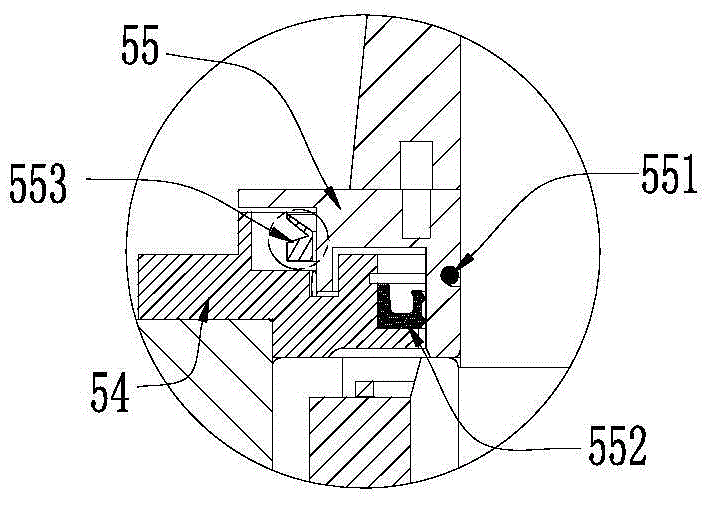

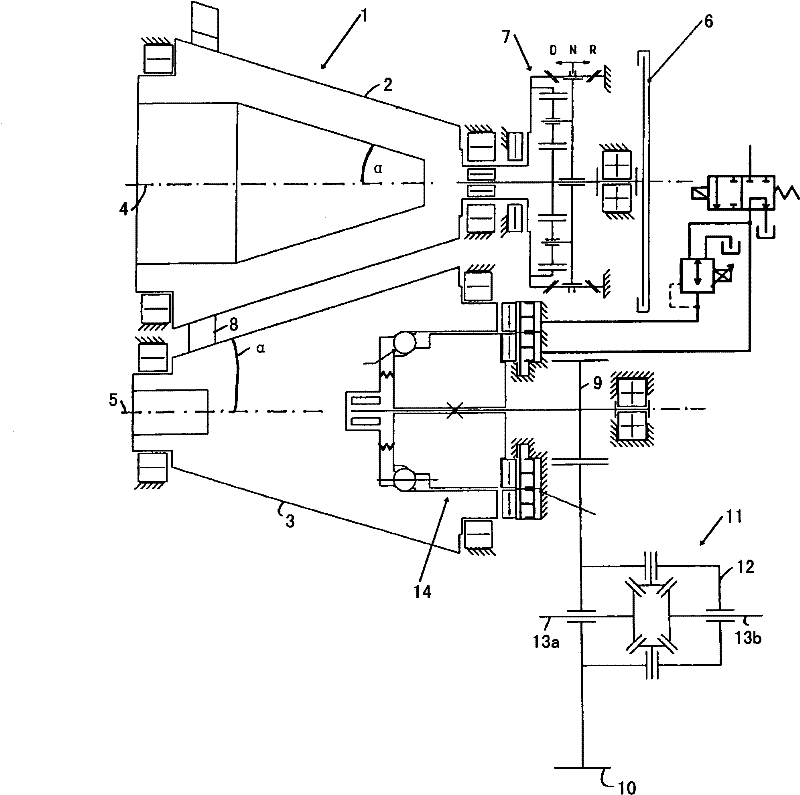

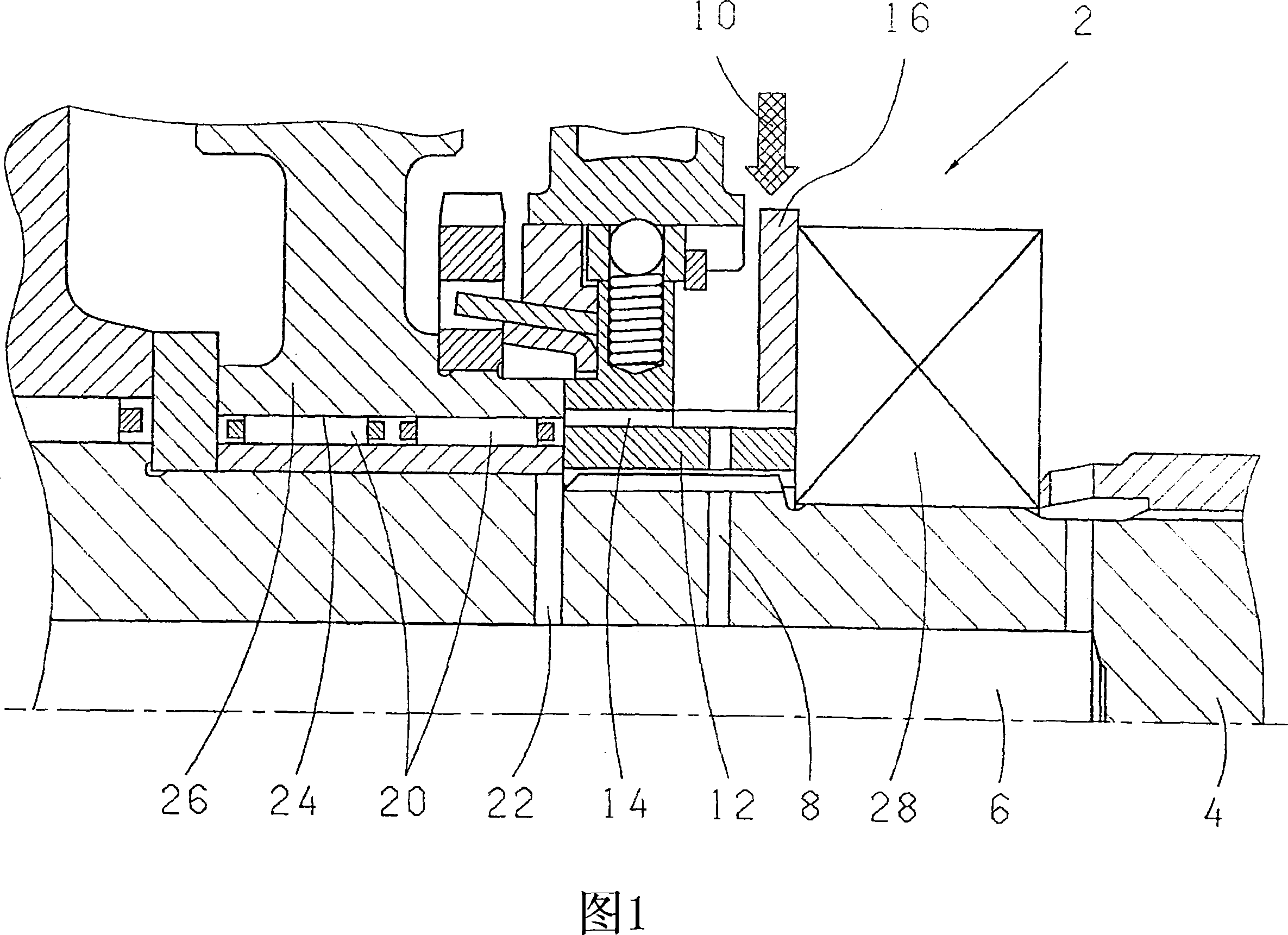

Oil supply device

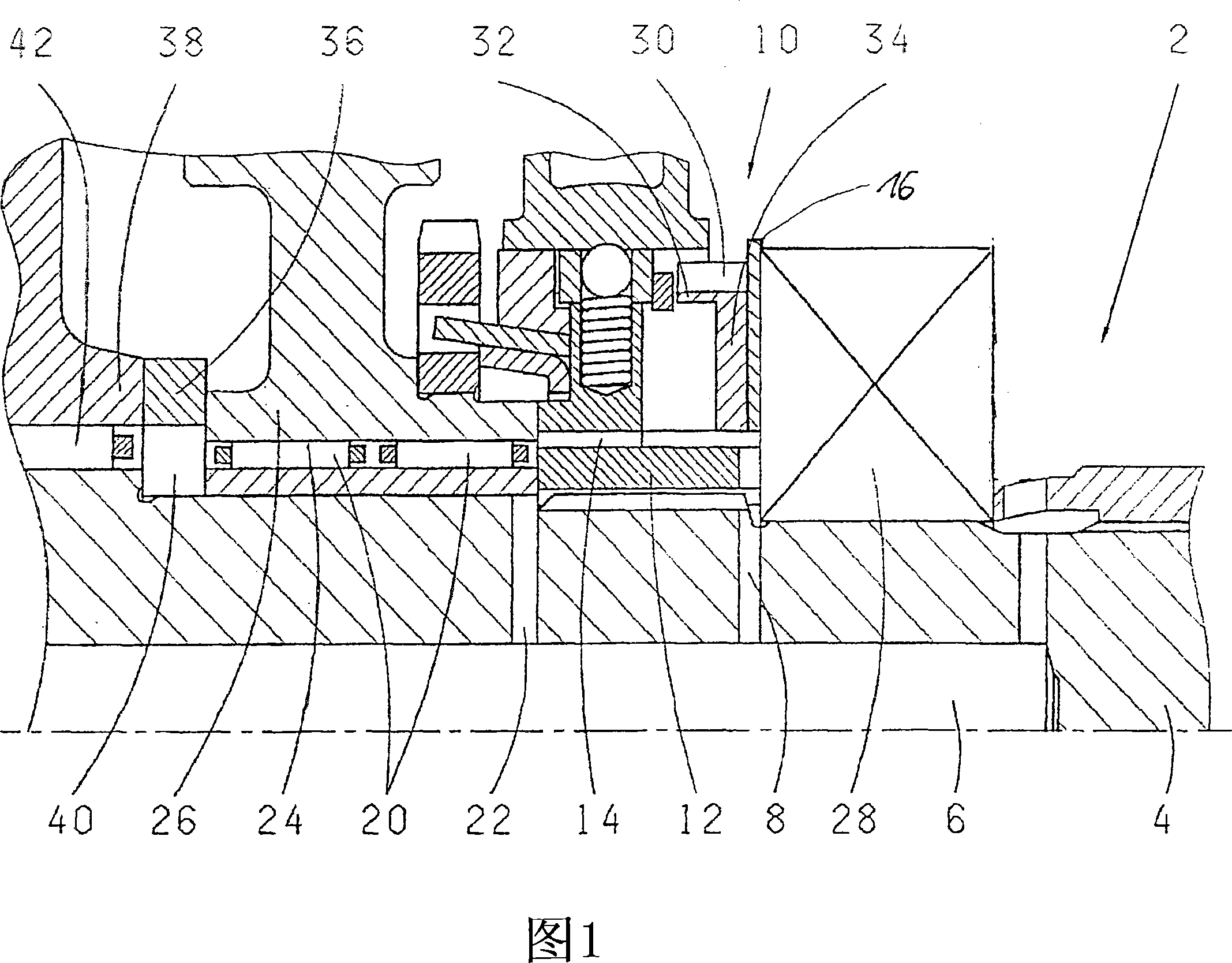

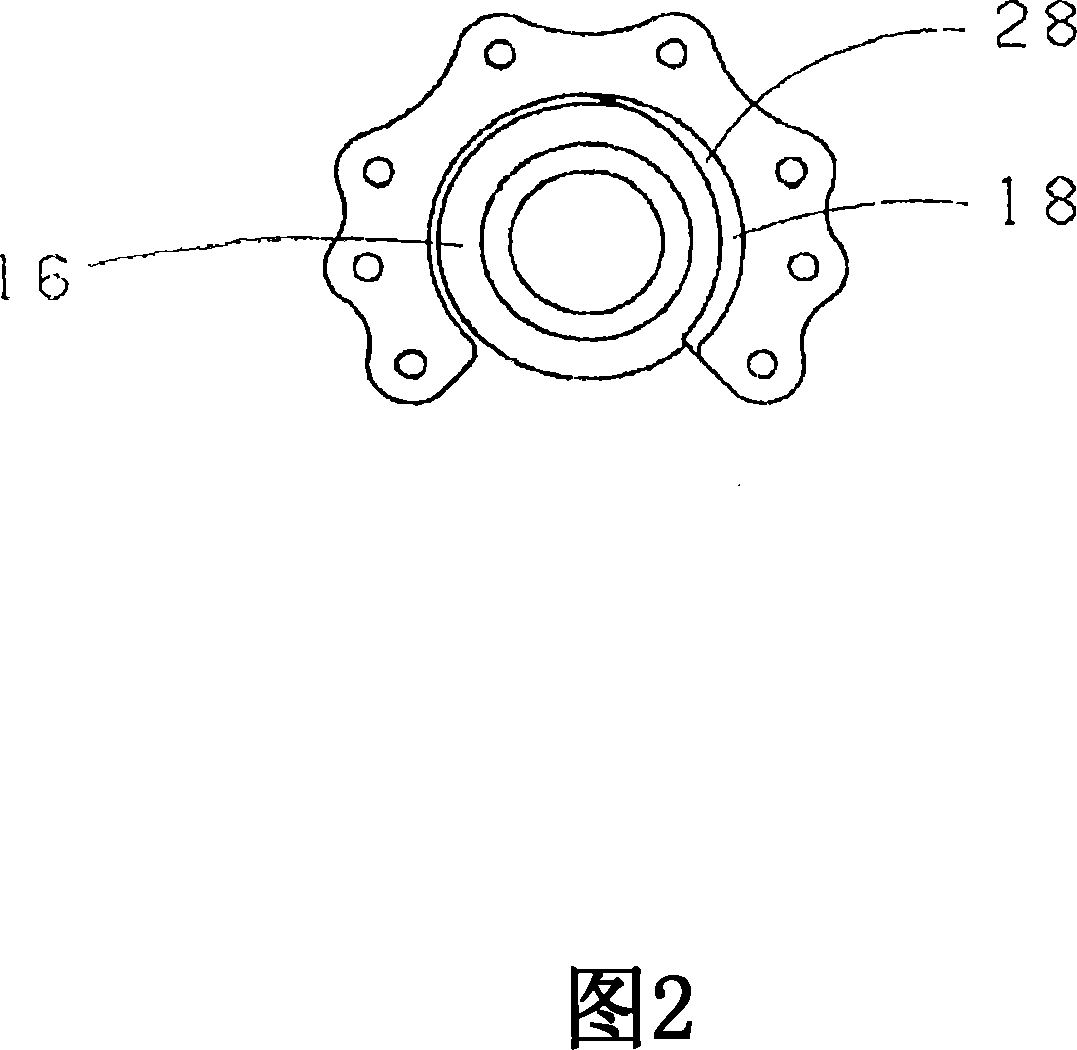

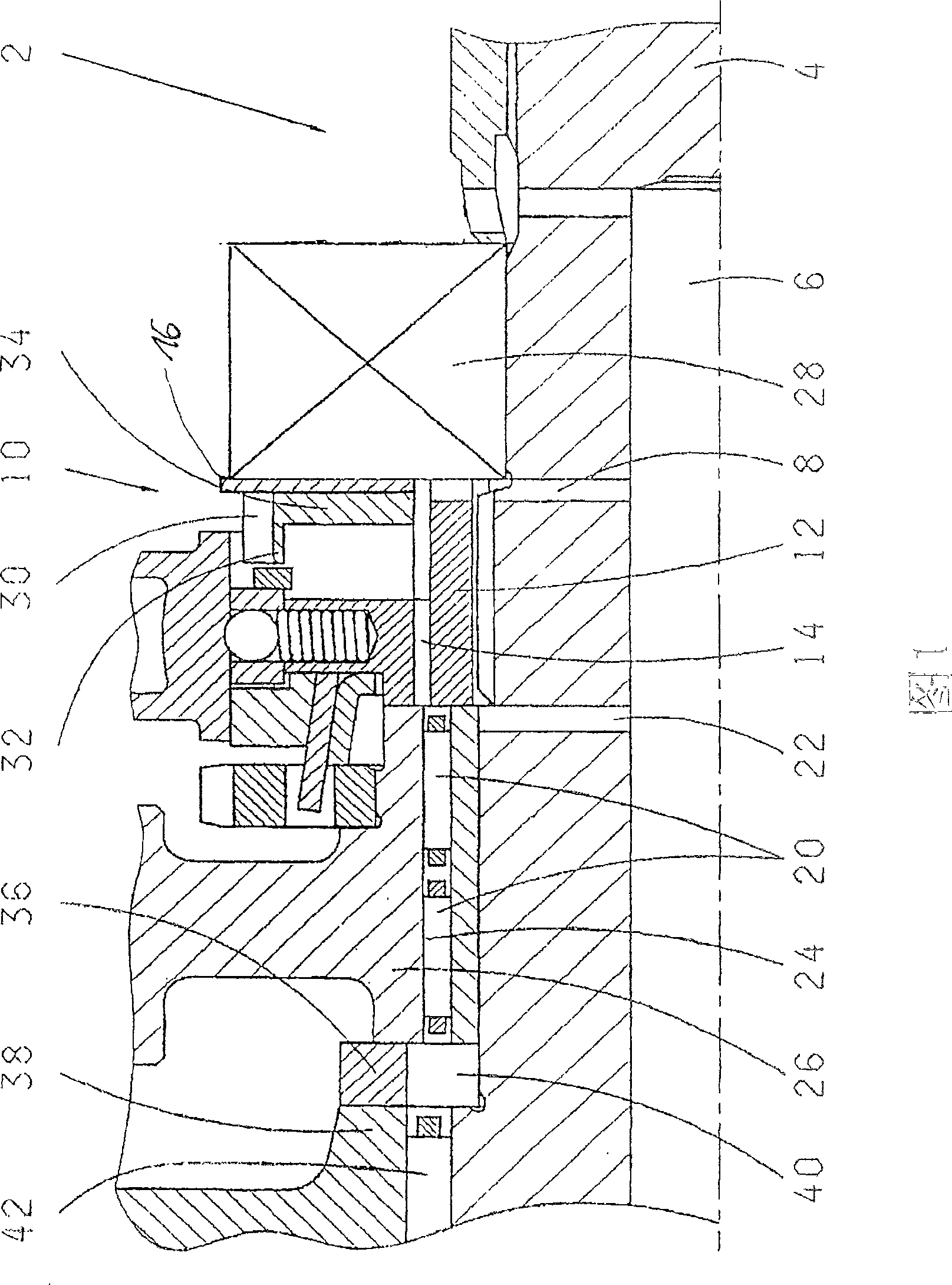

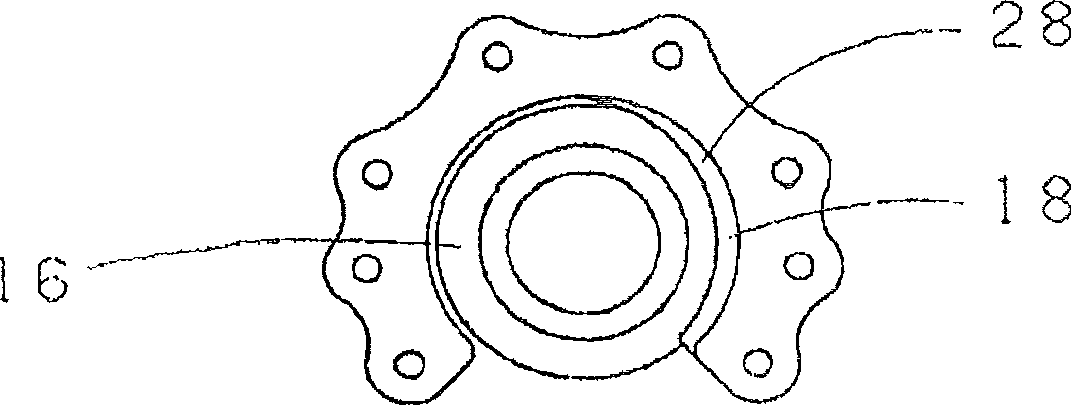

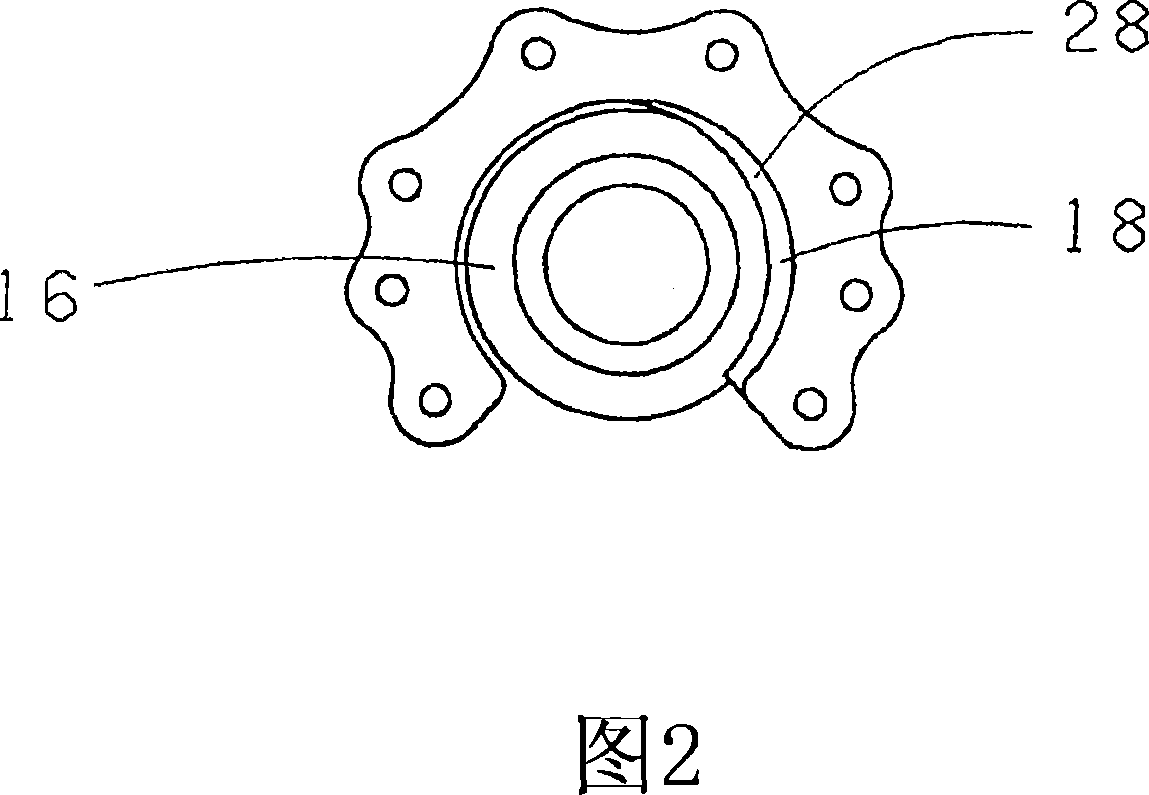

InactiveCN1989368AConvenient oil supplyMechanical actuated clutchesGear lubrication/coolingEngineeringOil supply

The invention relates to an oil supply device for a vehicle transmission (2) with: toothed wheels mounted on shafts; bearing arrangements inside of which toothed wheels and shafts are rotationally mounted, and; synchronizing devices (10), which are moved into the desired shifting positions via gear shift rods and gear shift forks by actuating a gear shift lever. One shaft (4) has an axially extending central hole (6) and at least one cross hole (8) for supplying oil. The oil supply device has holes (14) in a synchronizing body (12) of the synchronizing device (10), and a fixing plate (16) with a sickle-shaped cavity (18).

Owner:ZF FRIEDRICHSHAFEN AG

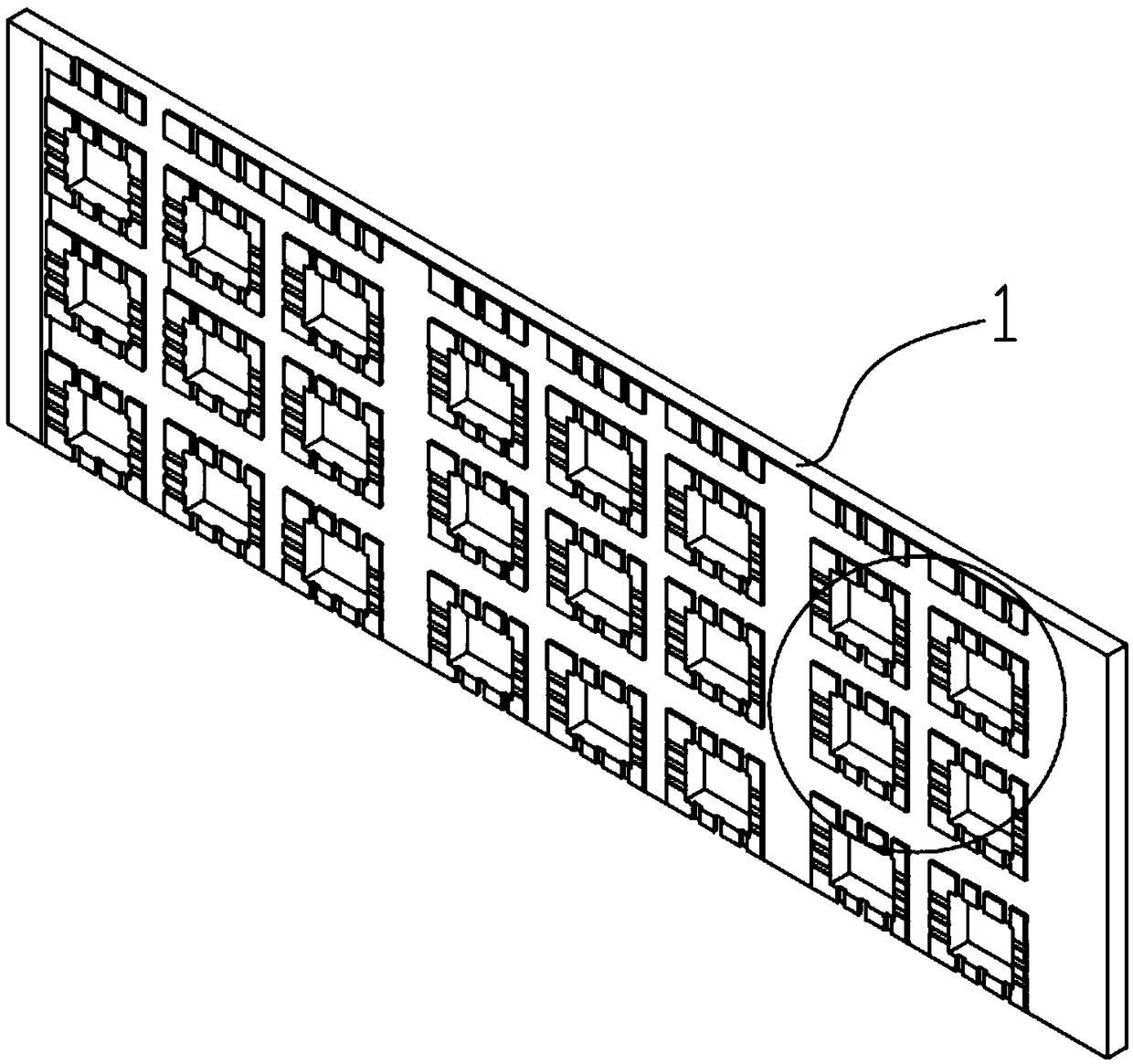

Drainage atomizing heating piece and manufacturing method thereof

The invention provides a drainage atomizing heating piece which comprises a plate body. The plate body is provided with a plurality of drainage channels and through holes. The drainage channels are indented in the surface of the plate body. The through holes run through the upper surface and the lower surface of the plate body. The drainage channels are communicated with the through holes. Due tothe structure, atomized cigarette liquid is smooth in taste and good in taste, the plate body can continuously conduct heating for atomizing cigarette liquid, the atomized cigarette liquid is broughtby external air through the through holes, the large heating area is obtained, meanwhile the requirement for large smoke amount is met, dry burning can be prevented, the liquid supply problem is effectively solved, and liquid supplying and atomizing are integrated. A manufacturing method of the drainage atomizing heating piece includes the steps of manufacturing the drainage channels in the uppersurface or the lower surface of the plate body and manufacturing the through holes in the plate body, wherein the through holes run through the upper surface and the lower surface of the plate body. The heating piece is easy to manufacture, batched operation is facilitated, and mechanical operation is also facilitated.

Owner:INNOKIN TECH

Cam shaft with matched central OCV

The invention discloses a cam shaft with a matched central OCV. The cam shaft comprises the central OCV which is connected with a first shaft neck at the front end of the cam shaft; a first oil path communicating with a first bearing cover is arranged in the first shaft neck; the two ends of the first oil path are separately connected with the central OCV and a main oil path in the cam shaft; and the cam shaft further comprises a limiting mechanism which is arranged in the first shaft neck for limiting and guiding oil in the first oil path into the main oil path. The cam shaft can effectively avoid the problem that oil supply to a VVT by the central OCV is affected due to the fact that a leakage rate of lubricating oil of the shaft neck is too great in an operation process of an engine, so that influences on performances of the engine are avoided.

Owner:CHERY AUTOMOBILE CO LTD

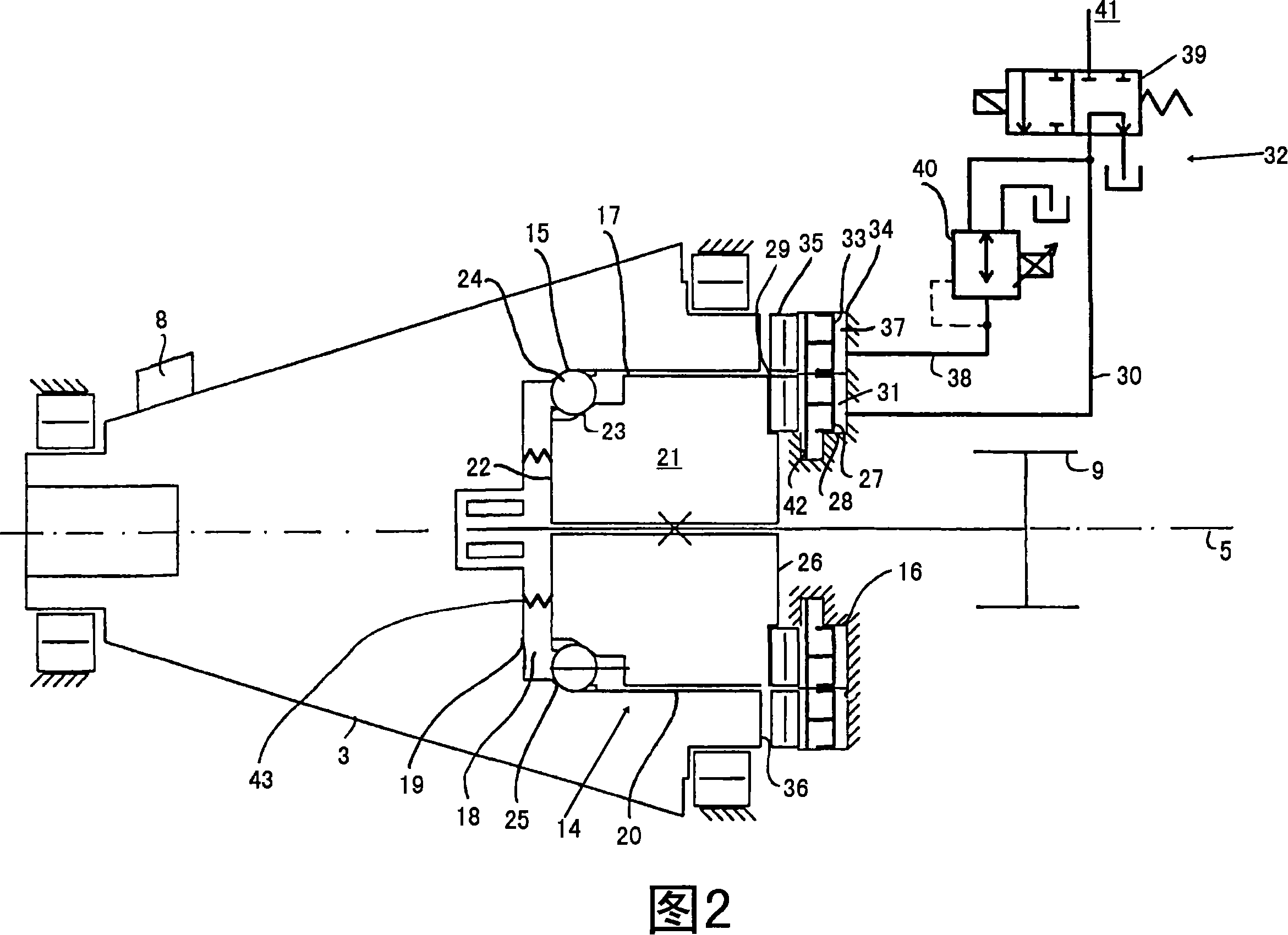

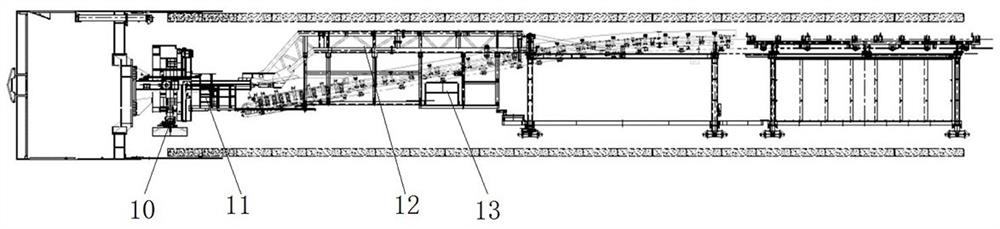

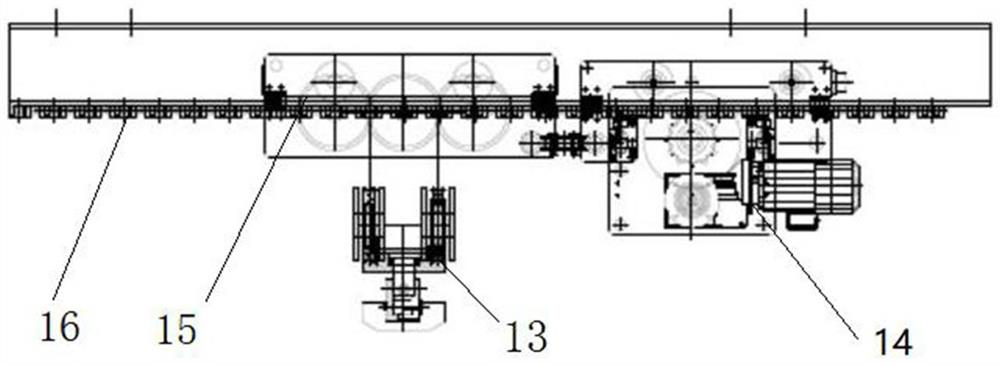

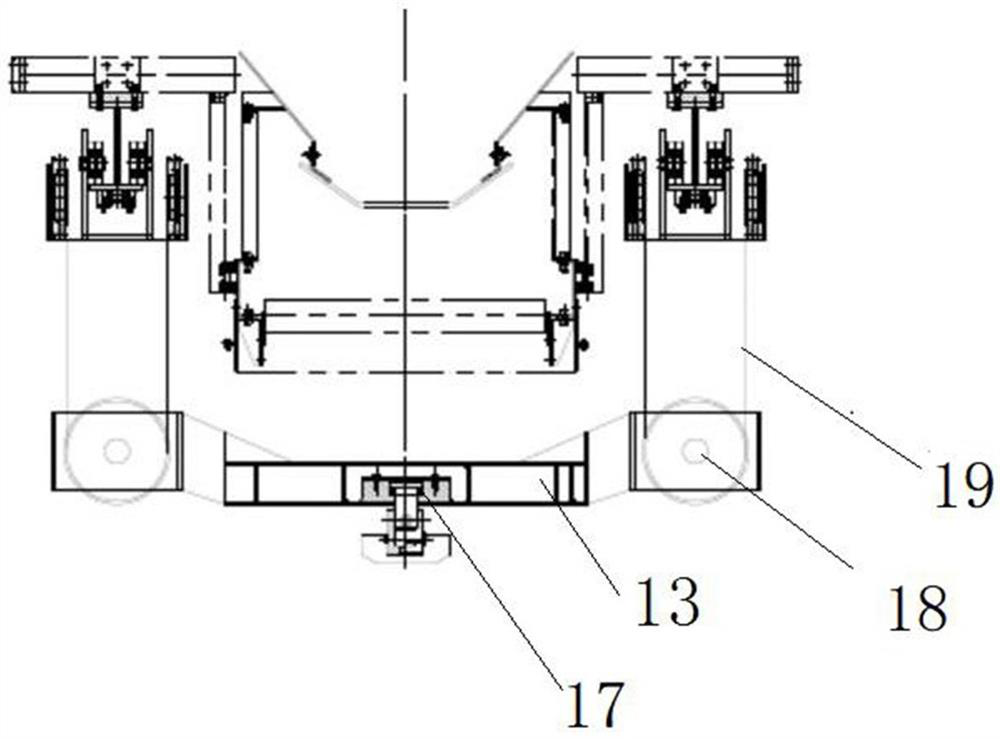

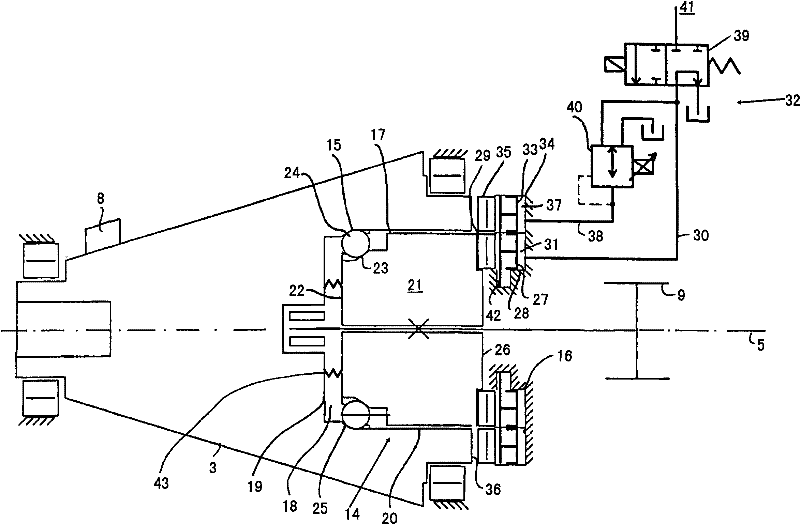

Segment crane and shield tunneling machine

PendingCN113294397APrevent flow awayConvenient oil supplyFluid-pressure actuator safetyUnderground chambersHydraulic circuitEngineering

The invention relates to a segment crane and a shield tunneling machine. The segment crane comprises two hydraulic oil cylinders and a hydraulic control system, wherein the hydraulic control system comprises two hydraulic loops; each hydraulic loop is provided with a rodless cavity oil way, a rod cavity oil way and a reversing valve; each reversing valve communicates the rodless cavity oil way and the rod cavity oil way of the corresponding hydraulic loop with an oil supply oil way and an oil return oil way so as to control the hydraulic oil cylinder to stretch and retract through the reversing valve; the reversing valve is provided with a locking middle position and used for controlling and locking the rod cavity oil way and the rodless cavity oil way of the corresponding hydraulic loop so as to lock the hydraulic oil cylinder; and a synchronous speed control valve is arranged on the rodless cavity oil way and / or the rod cavity oil way on the two hydraulic loops so as to realize synchronous action of the two hydraulic oil cylinders. Different control modes are selected according to actual working requirements, the two hydraulic oil cylinders can be controlled to act synchronously, the single hydraulic oil cylinder can also be controlled to act, and the actual working requirements are met.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

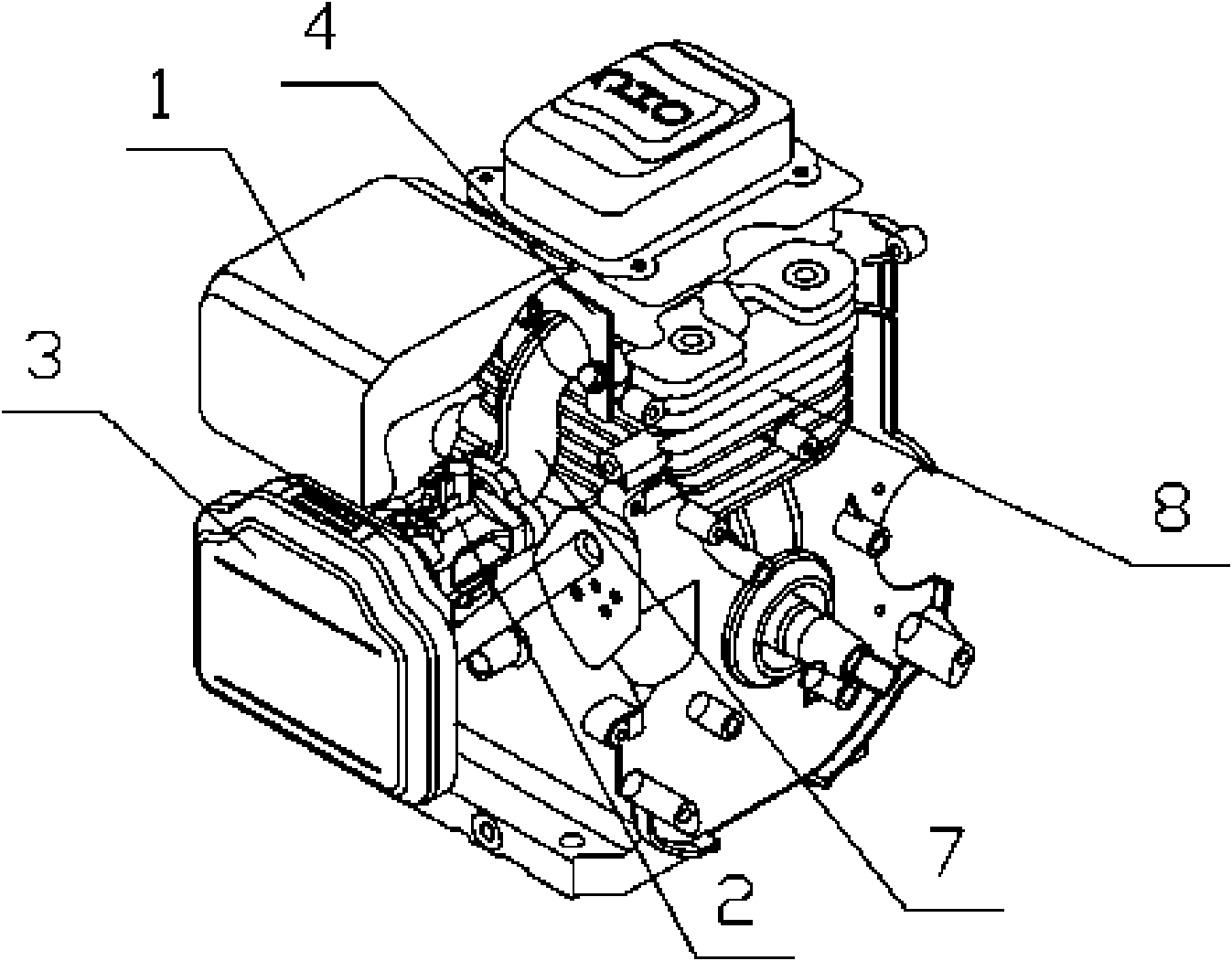

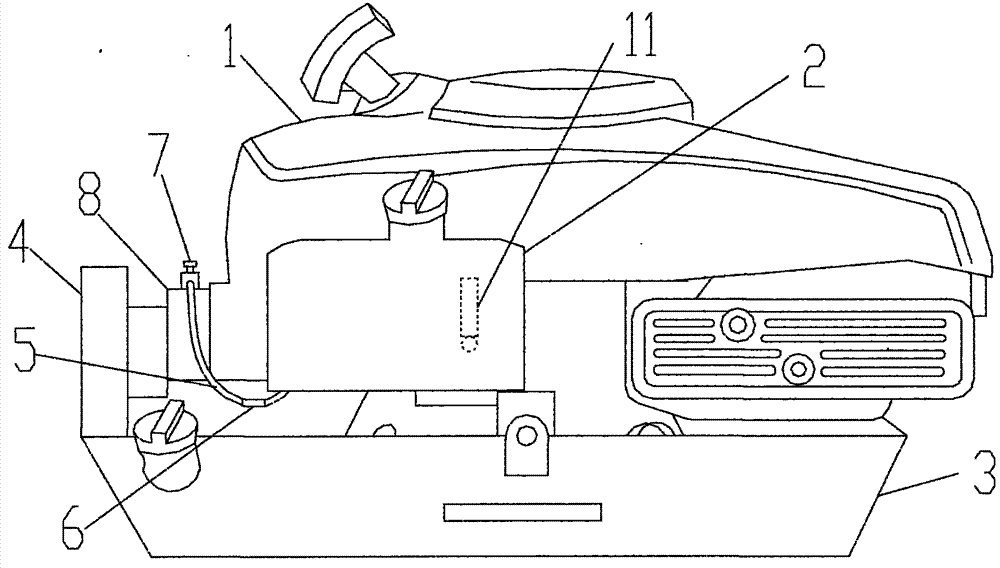

Fuel supply structure for general gasoline engines

InactiveCN101603482AConvenient oil supplyAvoid unreliabilityMachines/enginesLiquid fuel feedersAir filterCylinder head

The invention relates to a fuel supply structure for general gasoline engines, which comprises a fuel tank, a carburetor and an air filter. The structure is characterized in that one side of the fuel tank is arranged beside a cylinder head through a fuel tank bracket; the lower part of the fuel tank is supported by two support bolts connected with a crankcase body; the carburetor and the air filter are positioned below the fuel tank; one end of a mixed-gas outlet of the carburetor is communicated with an air inlet of the cylinder head through a rigid air inlet pipe; the carburetor is supported by an air inlet pipe; the air filter is connected with the carburetor through a bolt; an air inlet of the carburetor is communicated with the air filter; and an oil inlet of the carburetor is communicated with an oil outlet hole arranged on the bottom of the fuel tank. The invention has the advantages of ensuring compact layout of the fuel supply structure, increasing the overall aesthetic property of gasoline engines, improving fuel supply stability, replacing a gasoline pump with the air inlet pipe, reducing overall cost and improving cost performance.

Owner:LONCIN MOTOR

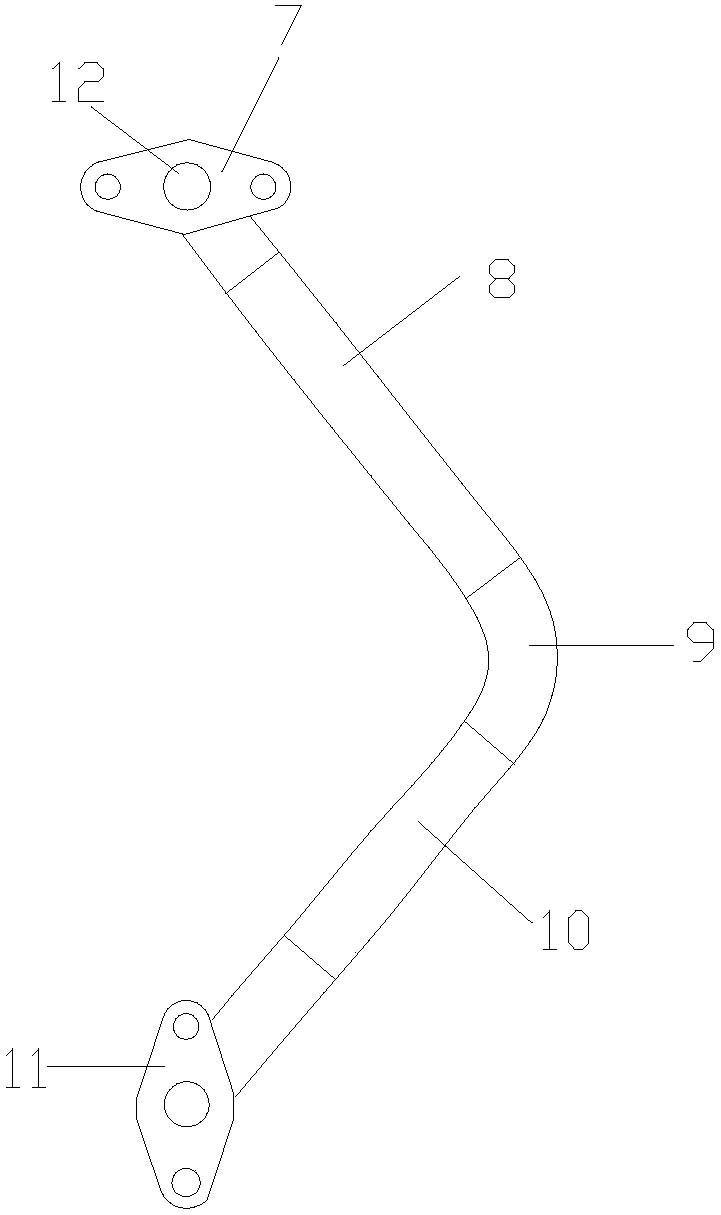

Lubricating oil pump oil-sucking pipe structure of numerically controlled machine tool

InactiveCN108202272AConvenient oil supplyAvoid enteringMaintainance and safety accessoriesMetal stripsNumerical control

The invention discloses a lubricating oil pump oil-sucking pipe structure of a numerically controlled machine tool. The lubricating oil pump oil-suction pipe structure structurally comprises an oil return pipe, a through opening, an eccentric sleeve, a pipe joint, a rotor and an oil sucking pipe. The inner end of the oil return pipe is provided with the rotor. The bottom end of the oil return pipeis connected with the pipe joint through the through opening. The outer ring of the pipe joint is fixedly provided with the eccentric sleeve. The eccentric sleeve is connected with the through opening through the pipe joint. The side end of the pipe joint is provided with the oil sucking pipe. The output end of the oil sucking pipe is fixedly connected with the eccentric sleeve. The oil sucking pipe is composed of a polygonal metal strip, a half-arc-shaped pipe segment, a circular pipe segment, a straight pipe segment and a U-shaped metal strip. The polygonal metal strip and the U-shaped metal strip are fixedly mounted and arranged on the left side and the right side of the oil sucking pipe correspondingly. The inner ends of both the polygonal metal strip and the U-shaped metal strip areprovided with filtering mesh belts correspondingly. According to the lubricating oil pump oil-sucking pipe structure of the numerically controlled machine tool, oil supplying by an oil pump is convenient and fast, the situation that air enters the oil pump is avoided, by filtering impurities in oil, cleaning is easy, and meanwhile, the working efficiency is improved.

Owner:天津鼎欣凯润机械设备维修有限公司

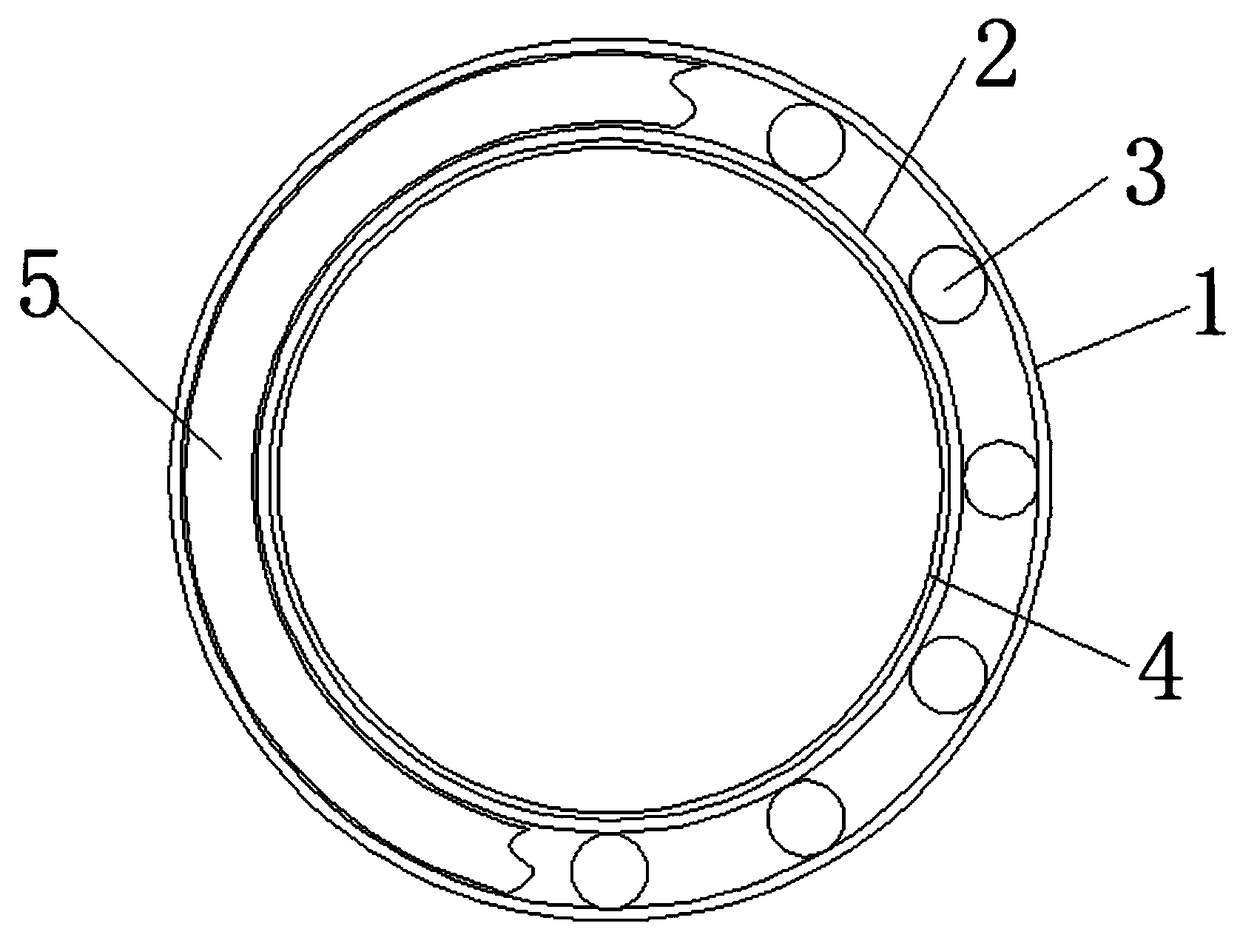

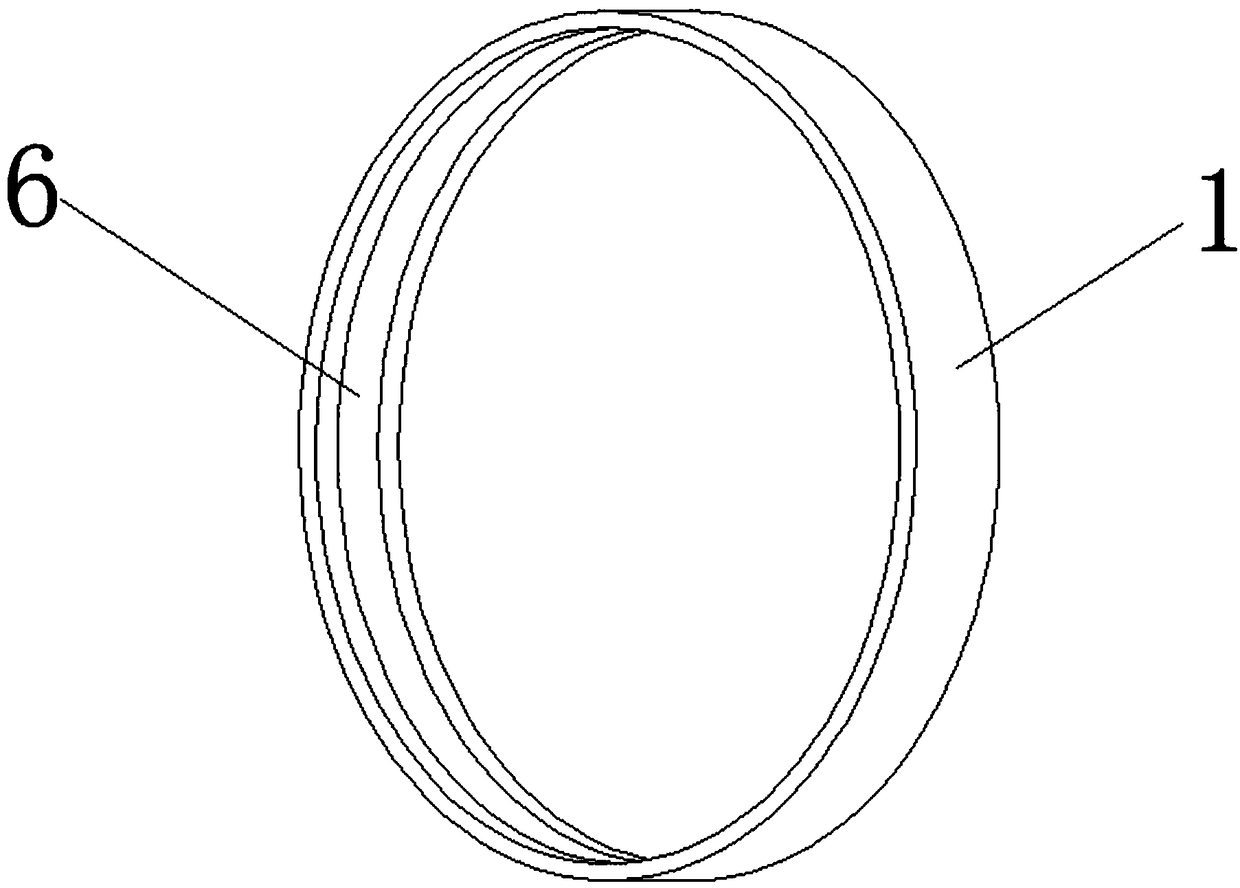

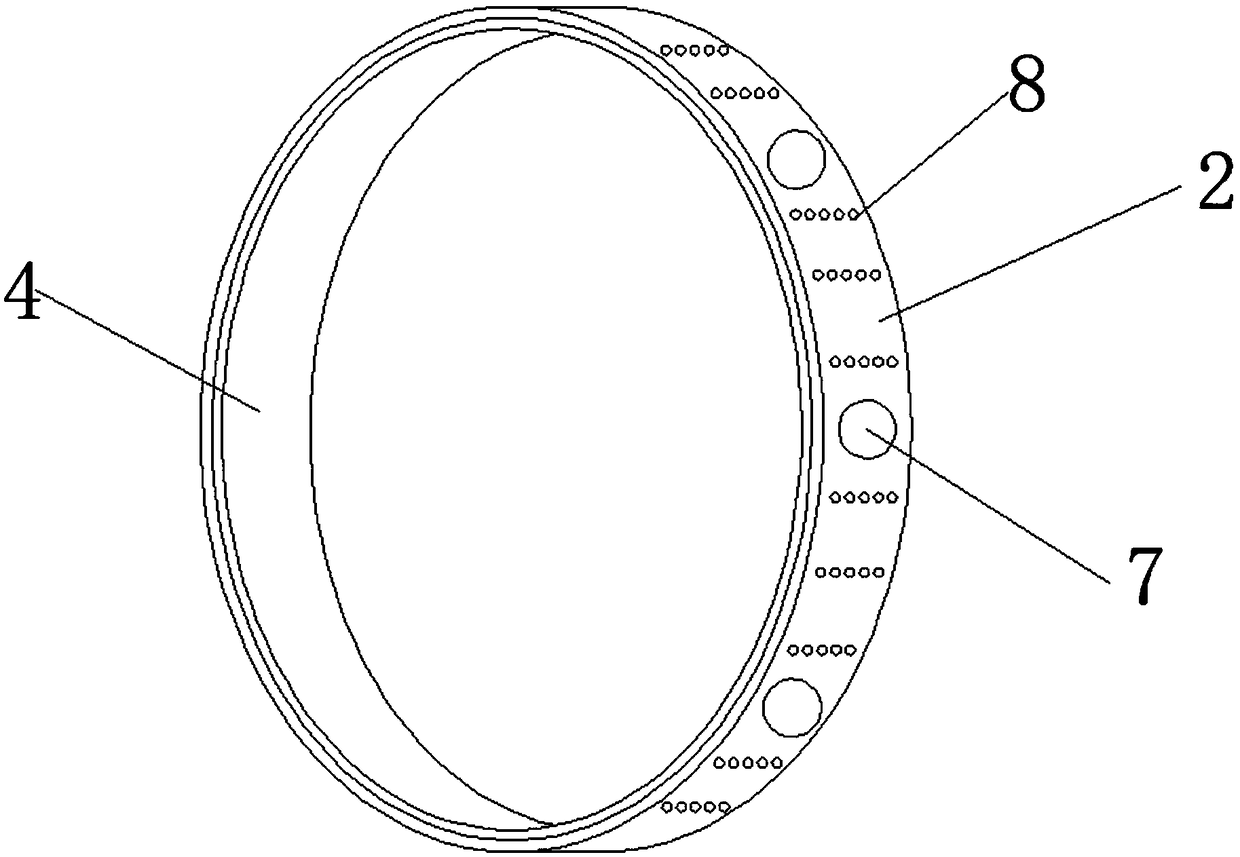

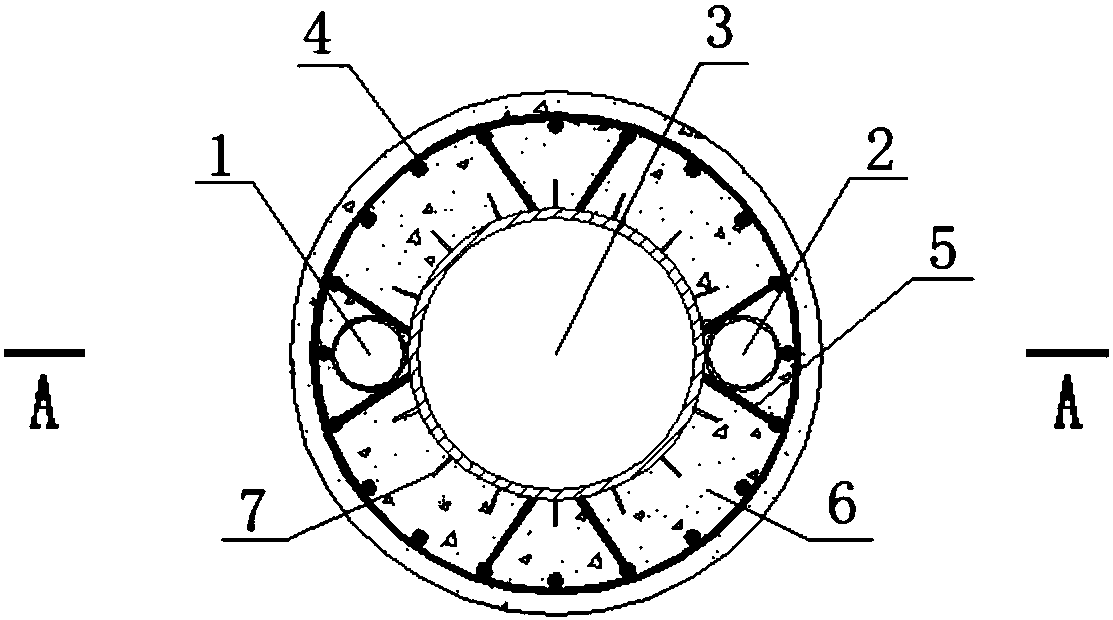

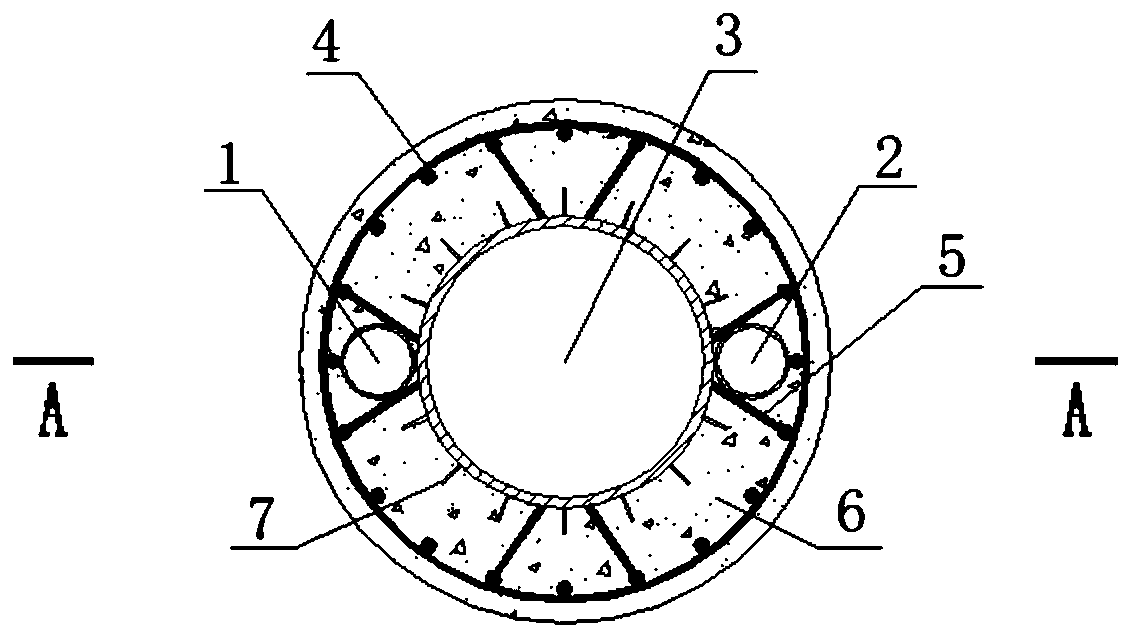

Novel ultrathin-wall high-abrasion-resisting ceramic bearing

PendingCN108361284AImprove working environmentModerately lubricatedBearing coolingEngineeringHardness

The invention discloses a novel ultrathin-wall high-abrasion-resisting ceramic bearing. The novel ultrathin-wall high-abrasion-resisting ceramic bearing comprises a bearing outer ring and a bearing inner ring. A ball groove is formed in the inner side wall of the bearing outer ring, balls are arranged in the ball groove, the multiple balls are arranged, and the bearing inner ring is arranged at one end of each ball. A plurality of ball fixing grooves are formed in the surface of the bearing inner ring, and lubricating oil suction grooves are formed between the ball fixing grooves. An abrasionresisting layer is arranged on the inner side of the bearing inner ring, and dustproof sound isolation rings are arranged on the two sides of the part between the bearing outer ring and the bearing inner ring. The novel ultrathin-wall high-abrasion-resisting ceramic bearing is simple in structure, friction is effectively reduced, the heat dissipation efficiency is greatly improved, and very good practicability is achieved; and the novel ultrathin-wall high-abrasion-resisting ceramic bearing can stably work under the environment that temperature changes are sharp, hardness is high, and abrasionresistance is achieved.

Owner:海宁科巍轴承科技有限公司

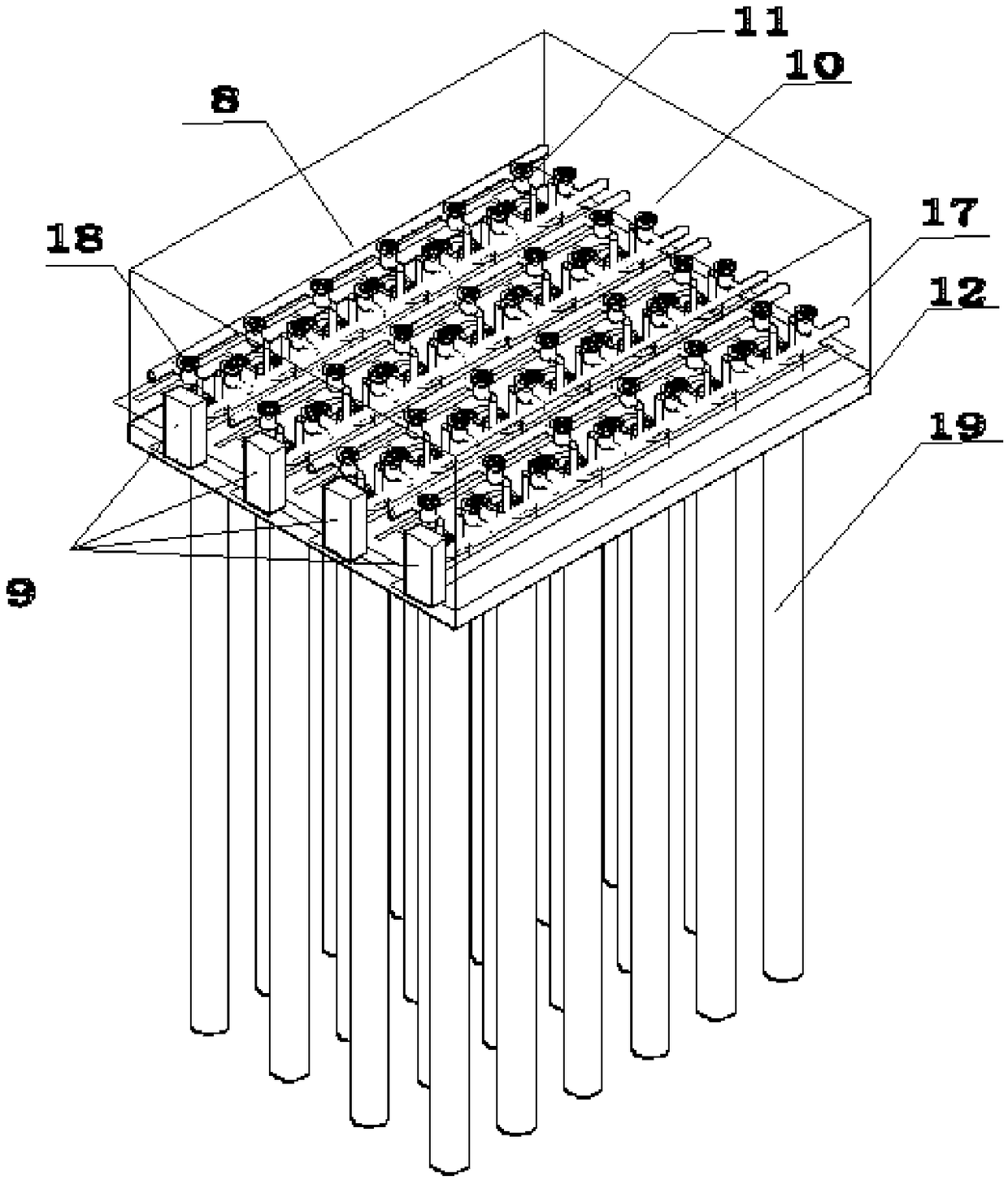

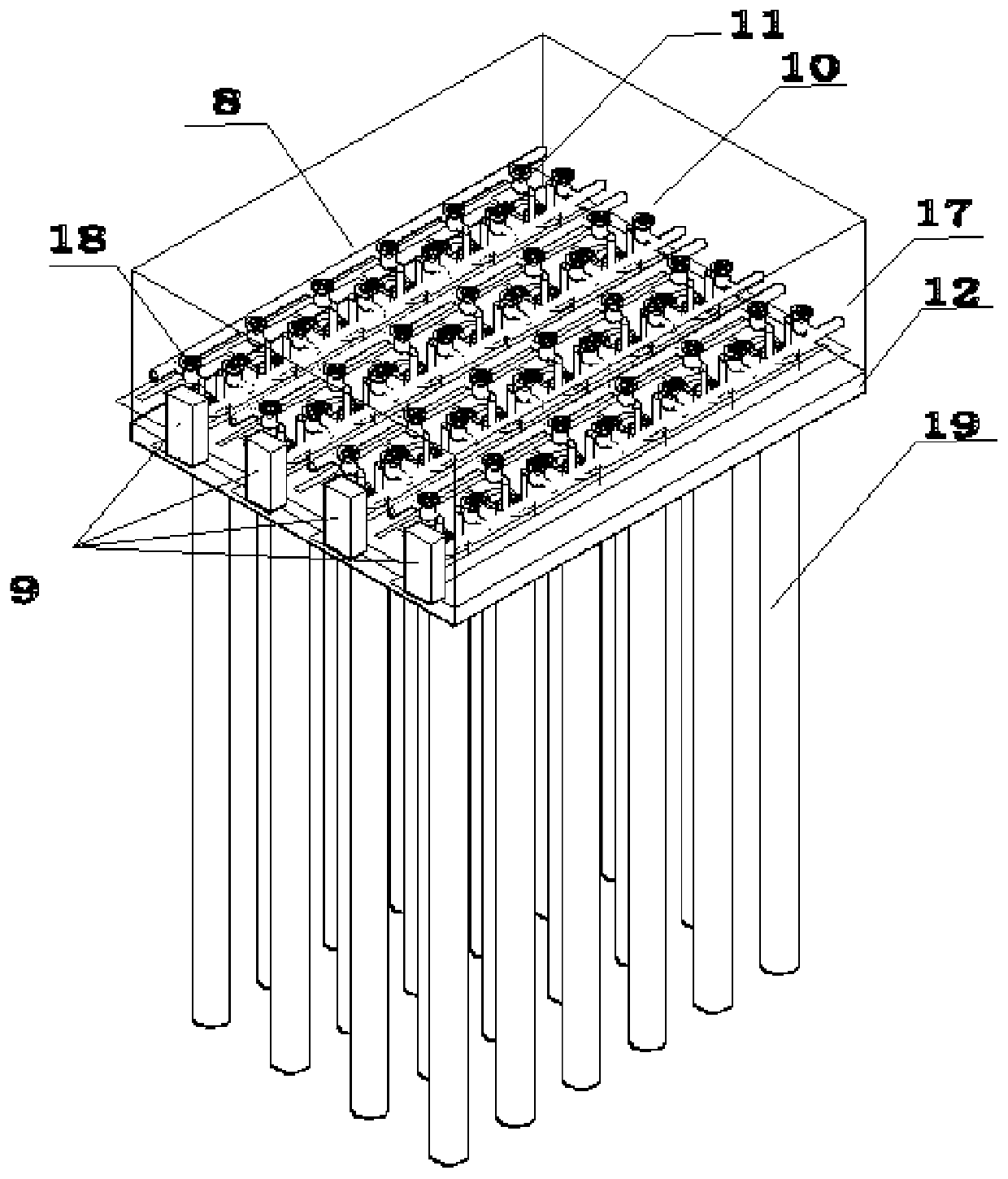

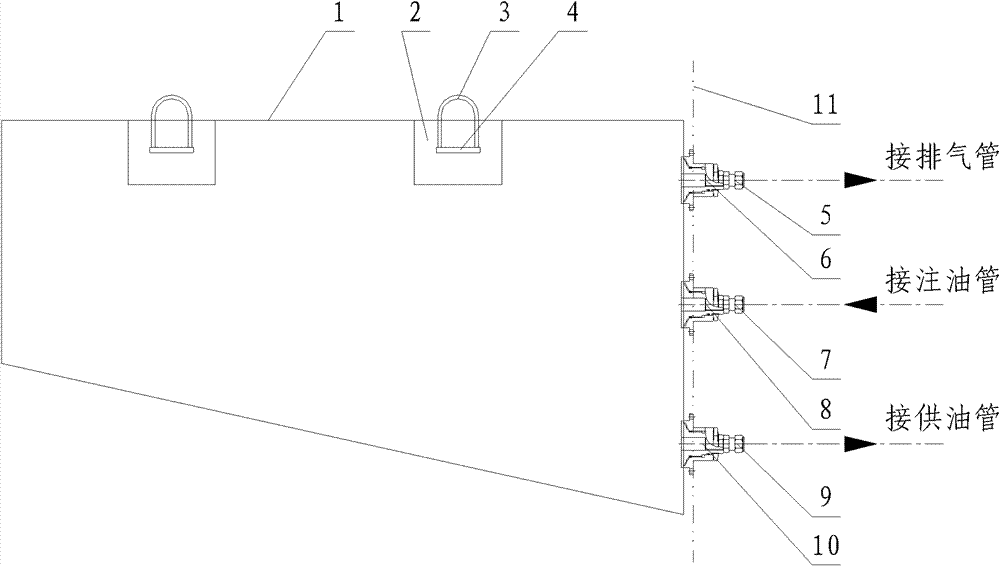

Oil storage pile group foundation and application method

ActiveCN108532623AMeet the bearing capacity requirementsRealize multiple utilizationFoundation engineeringExhaust valveEngineering

The invention discloses an oil storage pile group foundation and an application method. The oil storage pile group foundation comprises a bearing platform, multiple foundation piles, multiple oil in-out main pipes and multiple exhaust manifolds. The multiple foundation piles are arranged in a vertical matrix way; the bearing platform is arranged on the top part of the all foundation piles; each foundation pile comprises an oil storage tank, a reinforcement cage, a connecting reinforcement, a concrete shell and a bearing platform pre-embedded connecting piece; each oil storage tank is providedwith an oil in-out pipe and an exhaust pipe; each concrete shell is poured on the periphery of the corresponding oil storage tank; the oil in-out main pipes are connected with the oil in-out pipes incorresponding rows or columns; an oil in-out valve is arranged on a connecting pipeline; the exhaust manifolds are connected with the exhaust pipes in corresponding rows or columns; an exhaust valve is arranged on the connecting pipeline; and each exhaust manifold is connected with one pressure stabilizing device. The oil storage pile group foundation provided by the invention is used as a deep foundation of a high-rise building on one hand so as to meet the requirement of a baring capacity, and is used as an underground garage of the high-rise building on the other hand so as to realize the functions of parking, oiling and the like, so that the multiple utilization of a space and the safety, convenience and quickness in supplying oil to vehicles are realized.

Owner:NANJING UNIV OF TECH

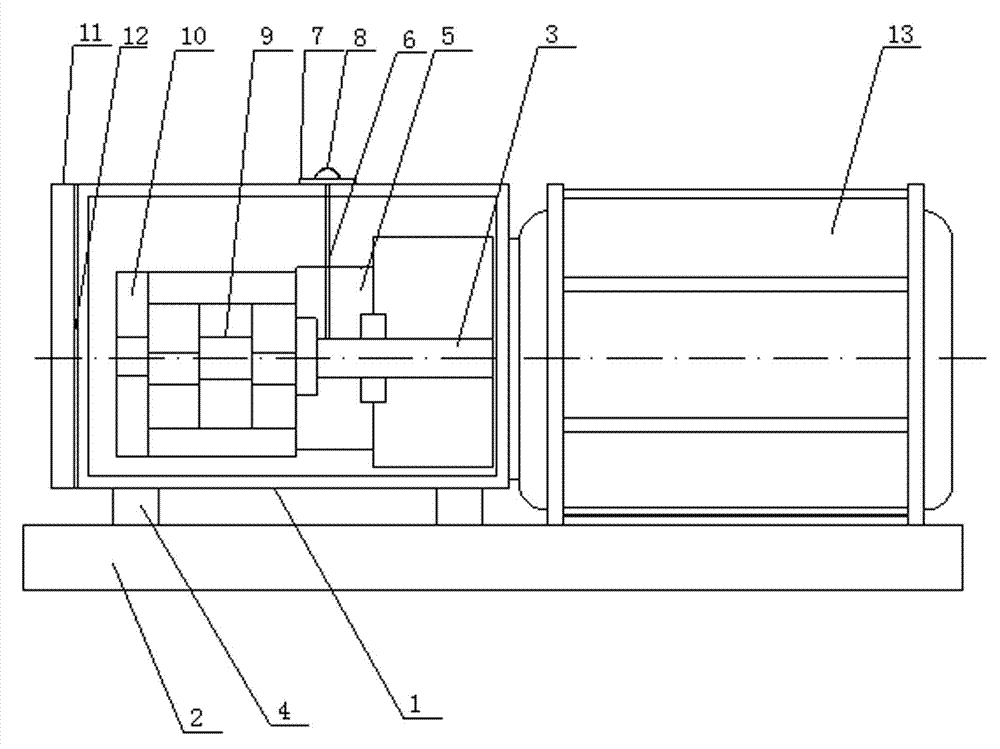

Ball crusher with double-rotor hydrostatic bearing structure

Owner:江苏智邦精工科技有限公司

A pressure reducing valve control circuit and its control method

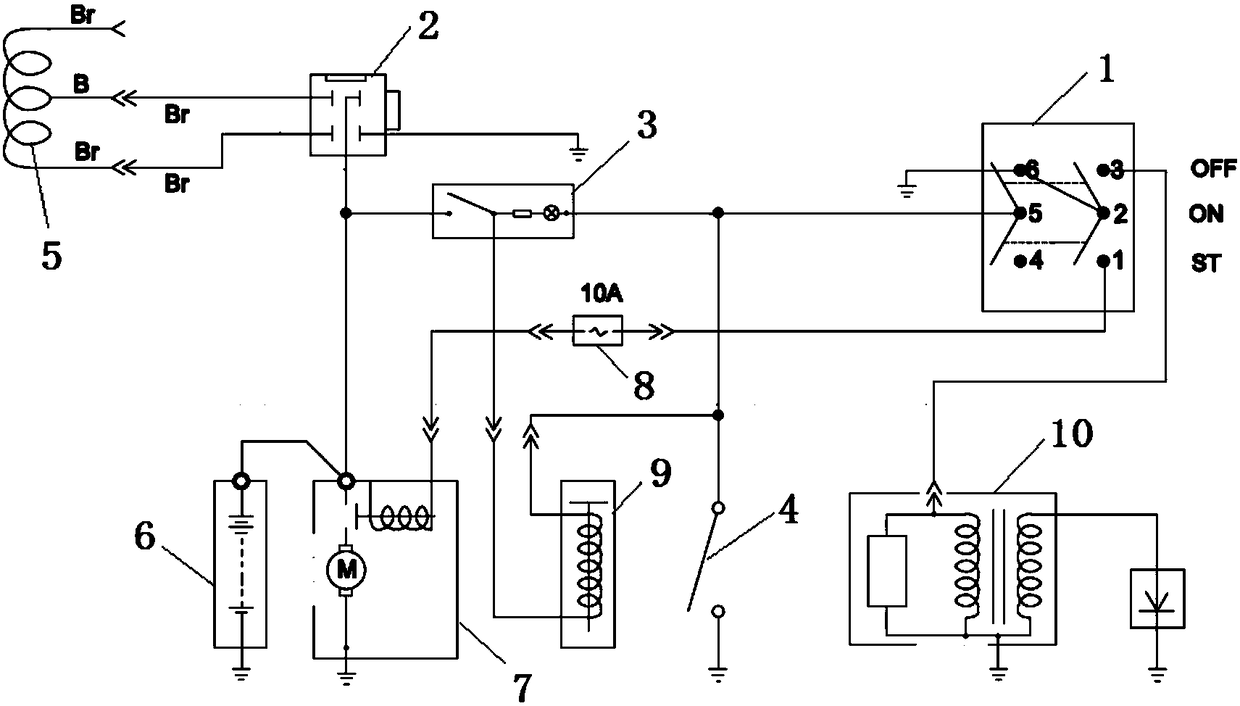

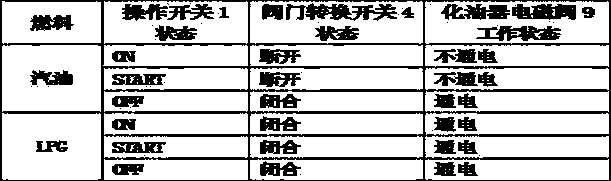

ActiveCN105863884BRunning unstableGuaranteed uptimeEngine controllersMachines/enginesSolenoid valveElectric machine

The invention discloses a pressure reducing valve control circuit and a control method thereof. The control circuit comprises an operating switch, a rectifier bridge, a valve change-over switch and a charge coil, wherein the charge coil is connected with a storage battery through the rectifier bridge; the operating switch is separately connected with a relay of a starting motor, an electromagnetic valve of a carburetor, the valve change-over switch and a flameout end of a high-voltage set; the relay of the starting motor and the electromagnetic valve of the carburetor are connected with an anode of the storage battery; and the valve change-over switch is in linkage connection with a microswitch of a pressure reducing valve. According to the control method of the pressure reducing valve control circuit, corresponding fuels are selected through the valve change-over switch, when the valve change-over switch rotates to a corresponding position, the corresponding microswitch is triggered, switch-on and switch-off of the electromagnetic valve connected with the microswitch are controlled, then switch-on and switch-off of an oil line of the carburetor can be controlled, and the circumstance that fuel oil in the carburetor combusts to cause unstable running of an engine is avoided; and by switching of different states of the operating switch, three states including starting, flameout and working of a generator are realized.

Owner:浙江康思特动力机械有限公司

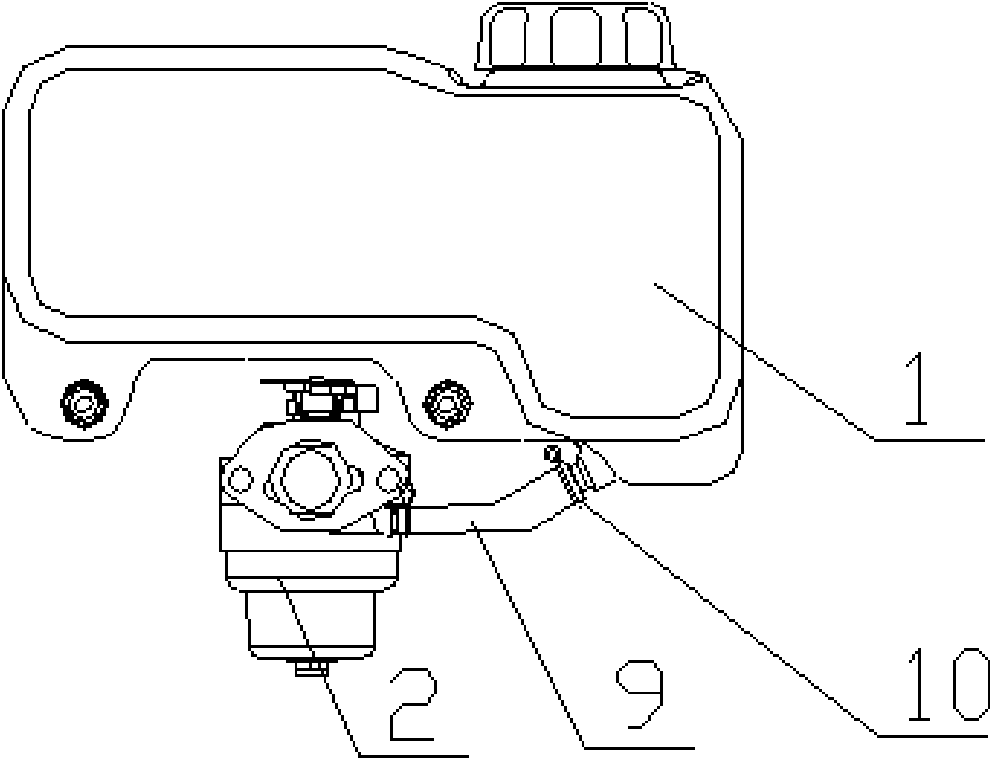

Engine oil and gasoline separate supply system for small two-stroke gasoline engines

InactiveCN104500166AConvenient oil supplyEasy to useMachines/enginesLubrication for crankcase compression enginesFuel tankGasoline

An engine oil and gasoline separate supply system for small two-stroke gasoline engines mainly comprises an oil tank, a carburetor and an intake branch pipe. An engine oil box is mounted a housing of a gasoline engine and communicated with the intake branch pipe through an engine oil pipe. A self-priming one-way valve and a flow regulating valve are disposed on the engine oil pipe. A negative pressure nozzle is disposed at an outlet of the engine oil pipe and communicated with the intake branch pipe. An engine oil inflow mechanism communicated with the intake branch pipe is added to an existing oil supply structure, engine oil and gasoline are automatically metered and mixed by suction generated by the small two-stroke gasoline engine started, oil supply for the existing small gasoline engine is greatly facilitated, and the engine oil and gasoline separate supply system has the advantages of simple structure, convenience in use and accuracy in metering.

Owner:李晓瑞

Oil supply device

InactiveCN100480549CConvenient oil supplyMechanical actuated clutchesGear lubrication/coolingEngineeringOil supply

The invention relates to an oil supply device for a vehicle transmission (2) with: toothed wheels mounted on shafts; bearing arrangements inside of which toothed wheels and shafts are rotationally mounted, and; synchronizing devices (10), which are moved into the desired shifting positions via gear shift rods and gear shift forks by actuating a gear shift lever. One shaft (4) has an axially extending central hole (6) and at least one cross hole (8) for supplying oil. The oil supply device has holes (14) in a synchronizing body (12) of the synchronizing device (10), and a fixing plate (16) with a sickle-shaped cavity (18).

Owner:ZF FRIEDRICHSHAFEN AG

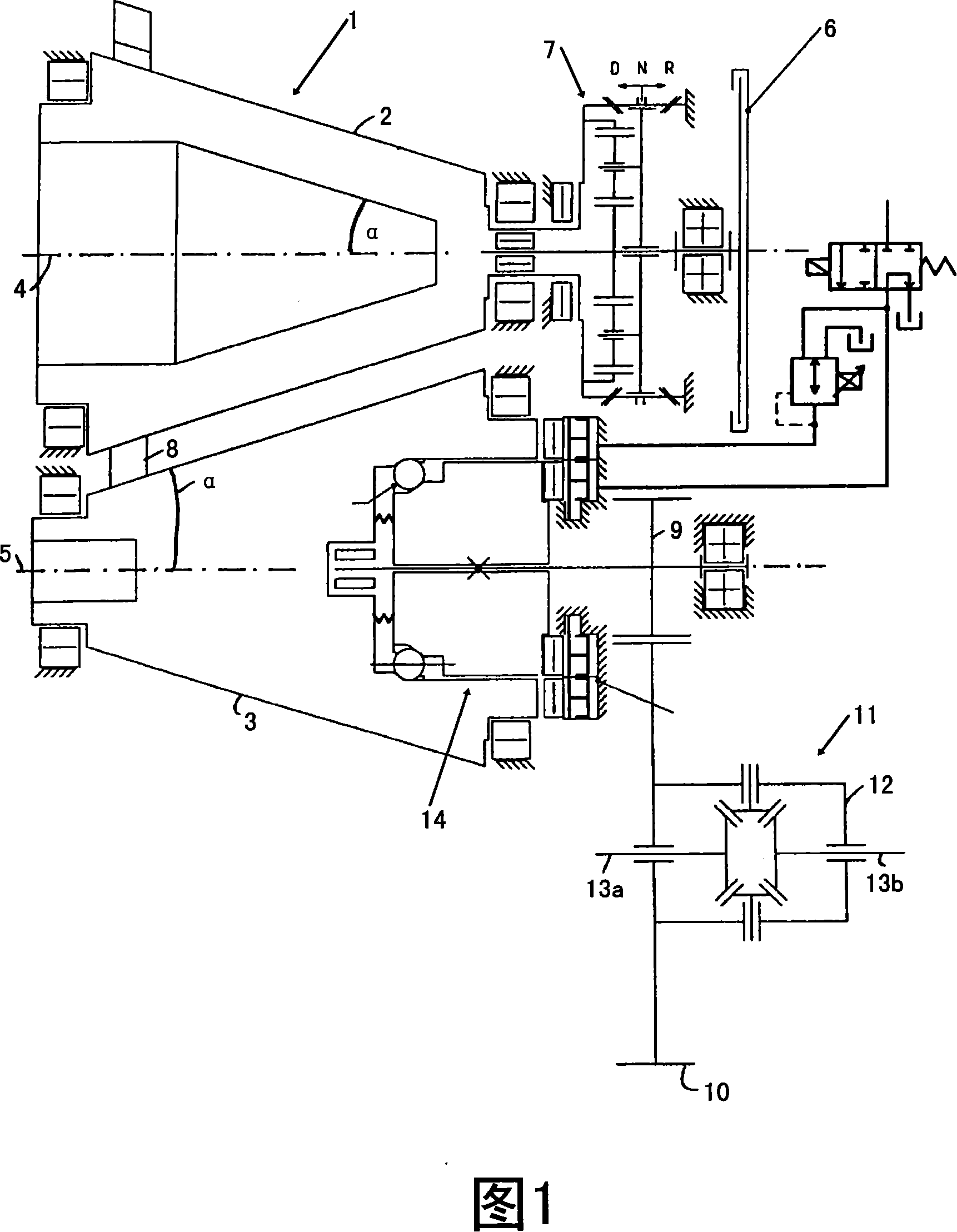

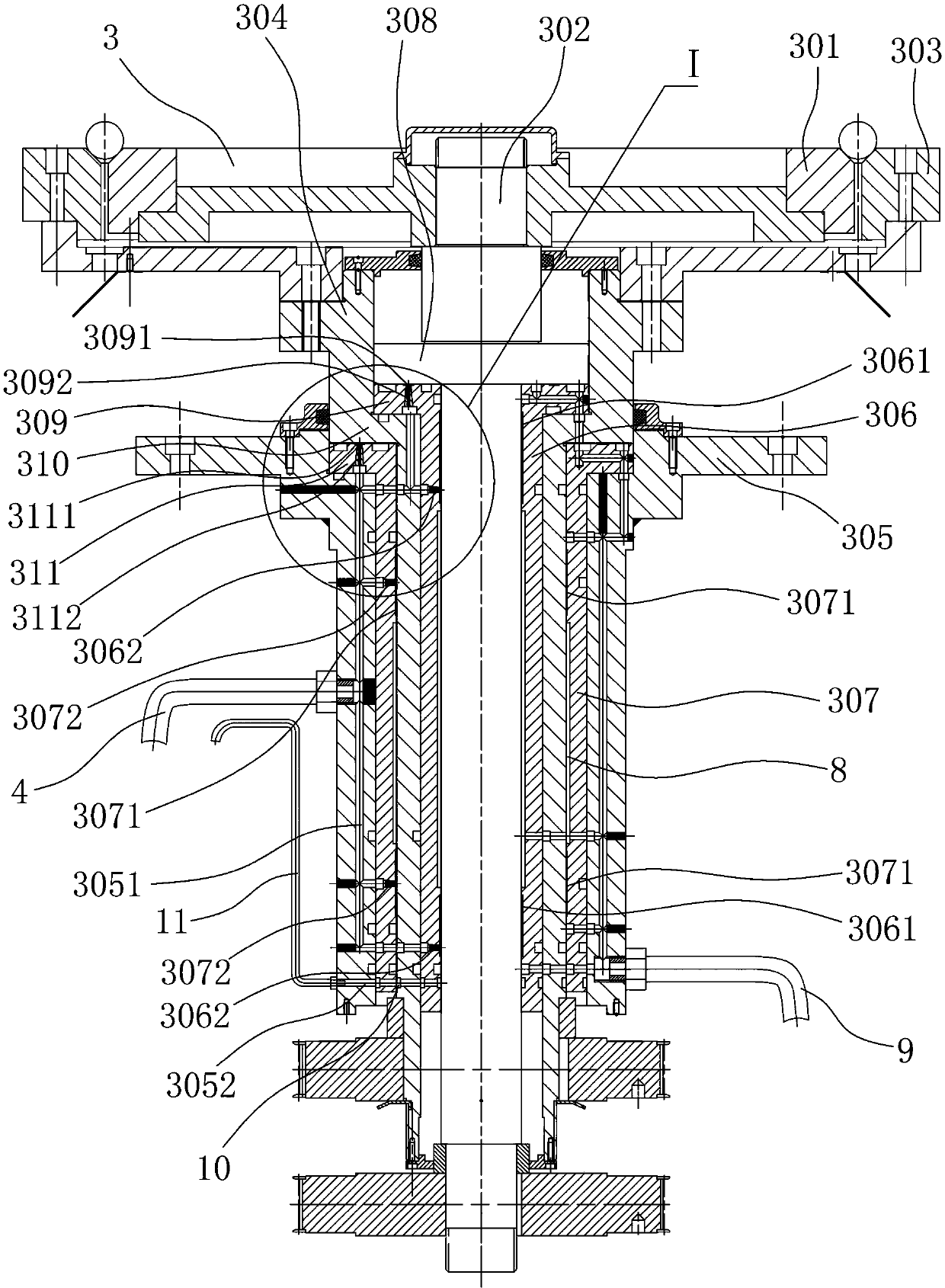

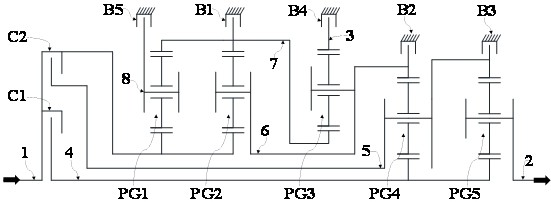

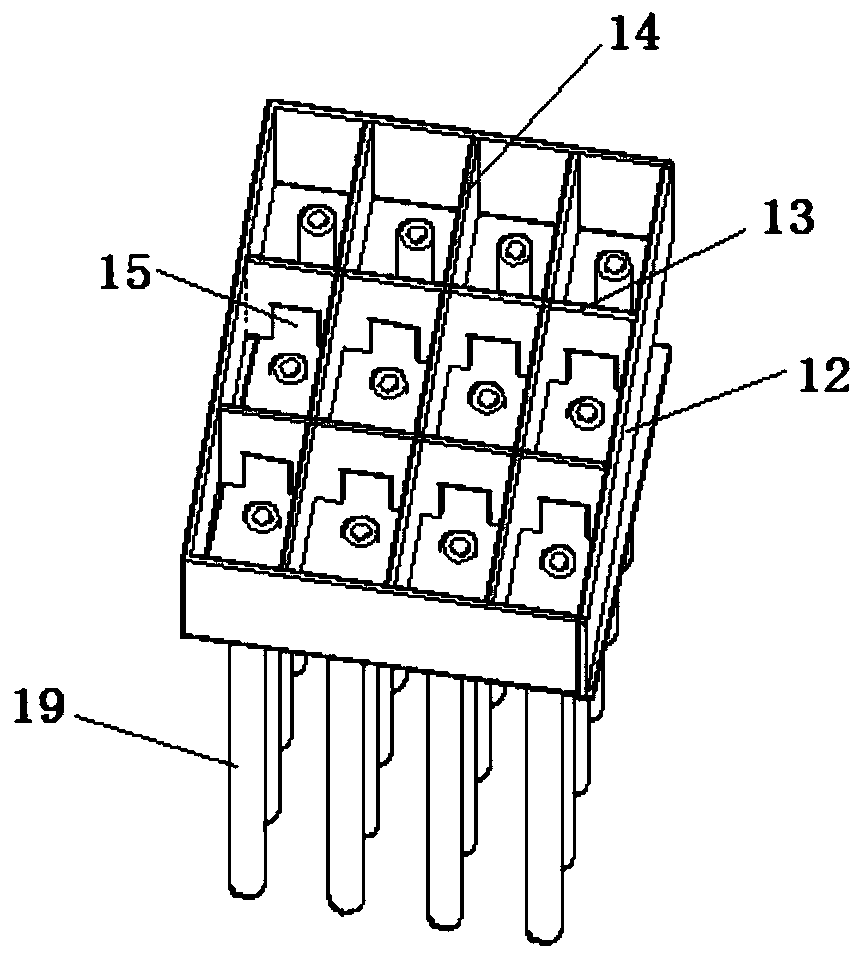

A multi-speed planetary gear transmission device

ActiveCN111536211BMany gearsWide transmission ratio rangeToothed gearingsTransmission elementsOil canGear wheel

The invention discloses a multi-gear planetary gear transmission device, which includes 8 rotating shafts, 5 brakes, 2 clutches, and 5 planetary rows. The invention uses 5 simple negative planetary rows and 7 shifting elements (including 5 brakes and 2 clutches), 2 clutches are arranged at the front end of the transmission instead of the middle of the transmission, so the oil supply is very convenient; 5 brakes are included, the number of brakes is large, and the planetary row arrangement can be embedded, and the pressure oil can be directly from the box The brake is supplied, and the structural layout is more compact; each gear position closes 2 shift elements, which can realize 12 forward gears and 1 reverse gear, with more gear numbers and a wider range of transmission ratios.

Owner:BEIHANG UNIV

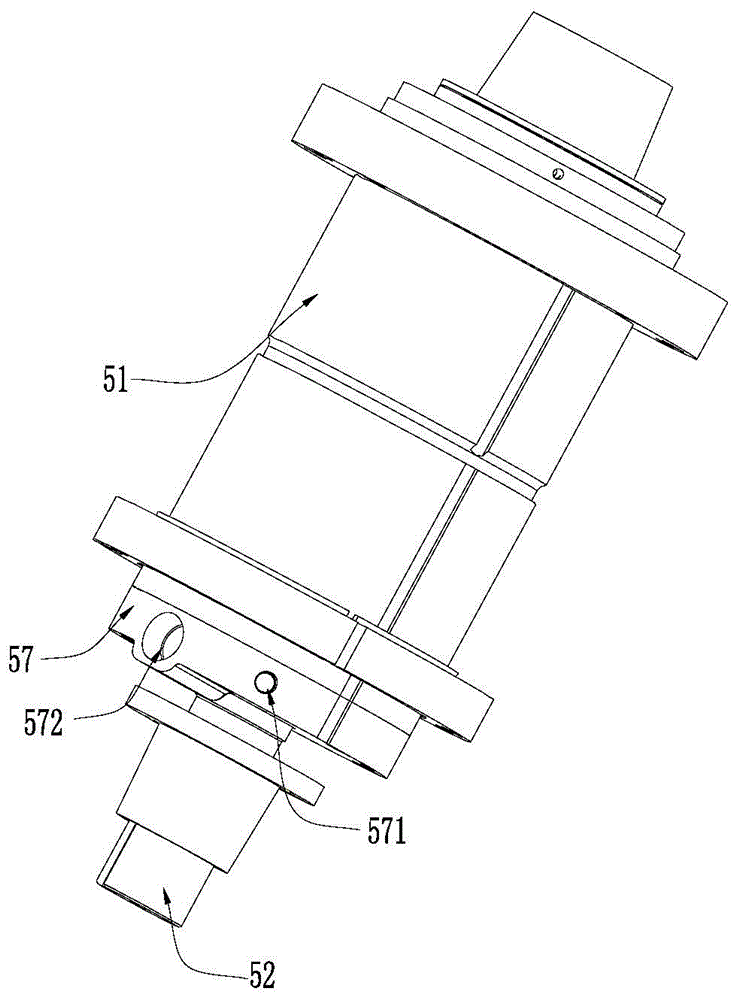

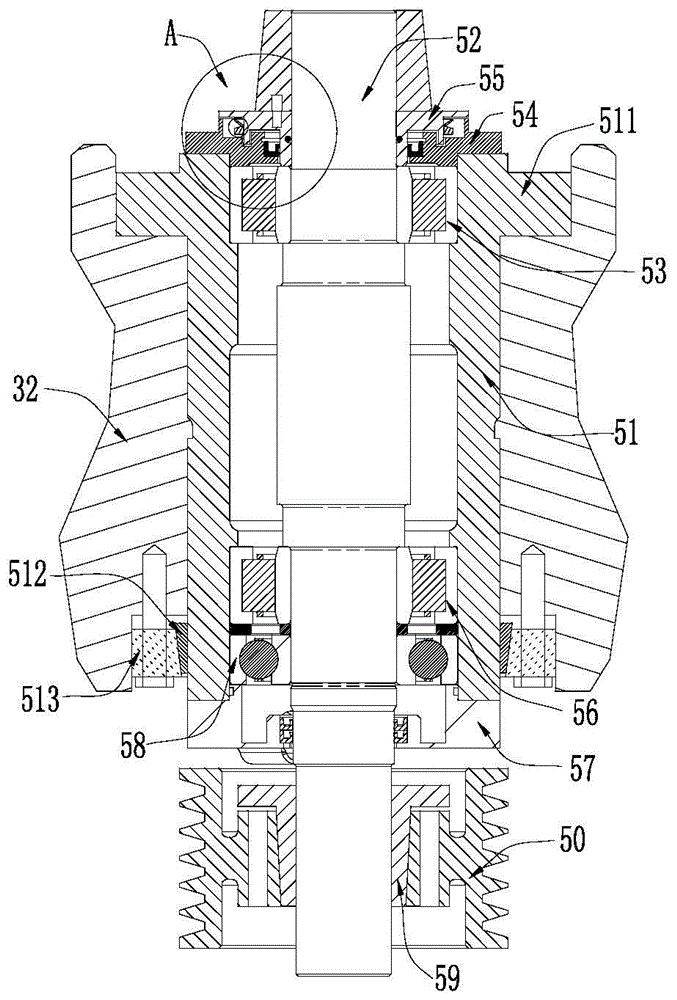

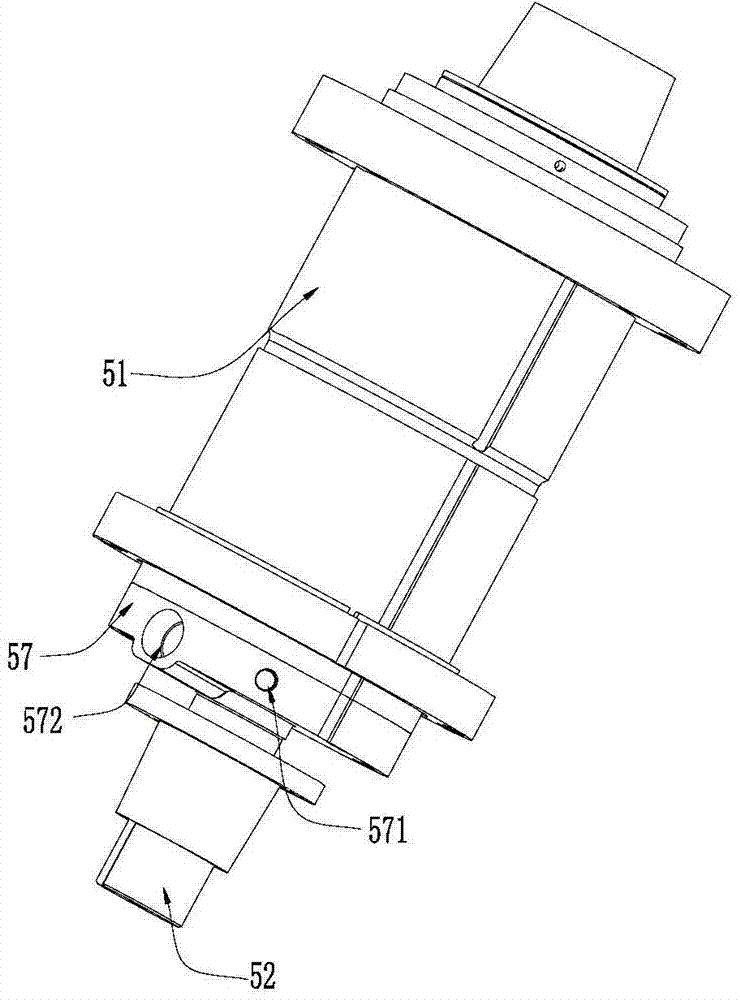

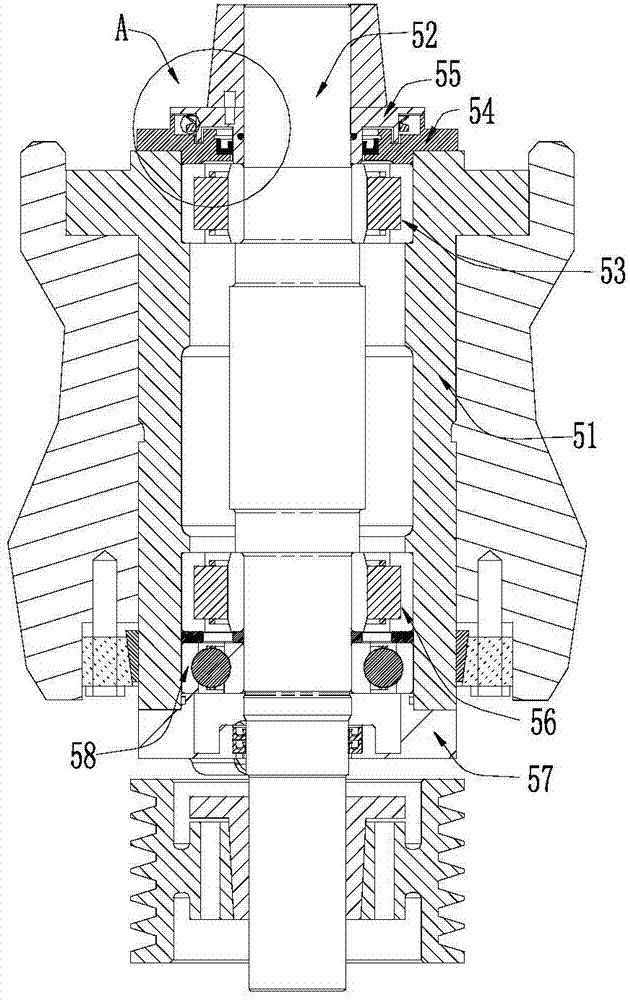

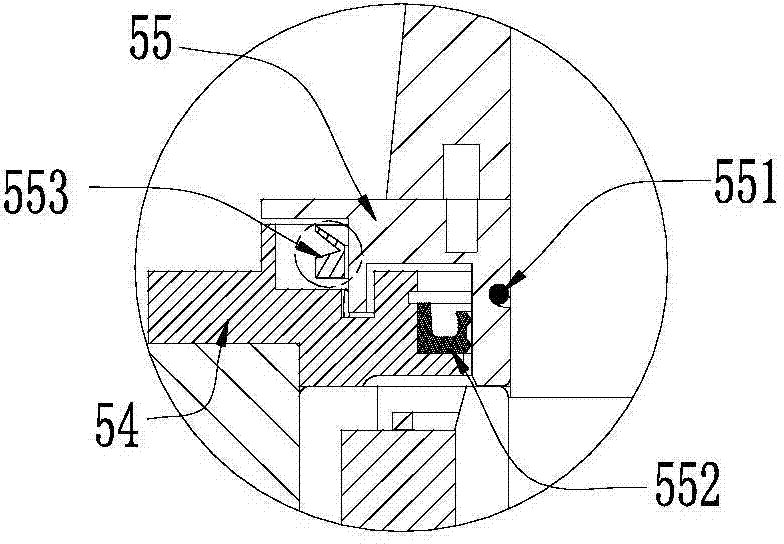

Main shaft structure on a vertical shaft impact crusher

ActiveCN104722373BImprove enduranceGuaranteed stabilityGrain treatmentsBearing unit rigid supportStructural engineeringCrusher

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

An oil storage pile group foundation and its application method

ActiveCN108532623BMeet the bearing capacity requirementsRealize multiple utilizationFoundation engineeringExhaust valveReinforced concrete

The invention discloses an oil storage pile group foundation and an application method. The oil storage pile group foundation comprises a bearing platform, multiple foundation piles, multiple oil in-out main pipes and multiple exhaust manifolds. The multiple foundation piles are arranged in a vertical matrix way; the bearing platform is arranged on the top part of the all foundation piles; each foundation pile comprises an oil storage tank, a reinforcement cage, a connecting reinforcement, a concrete shell and a bearing platform pre-embedded connecting piece; each oil storage tank is providedwith an oil in-out pipe and an exhaust pipe; each concrete shell is poured on the periphery of the corresponding oil storage tank; the oil in-out main pipes are connected with the oil in-out pipes incorresponding rows or columns; an oil in-out valve is arranged on a connecting pipeline; the exhaust manifolds are connected with the exhaust pipes in corresponding rows or columns; an exhaust valve is arranged on the connecting pipeline; and each exhaust manifold is connected with one pressure stabilizing device. The oil storage pile group foundation provided by the invention is used as a deep foundation of a high-rise building on one hand so as to meet the requirement of a baring capacity, and is used as an underground garage of the high-rise building on the other hand so as to realize the functions of parking, oiling and the like, so that the multiple utilization of a space and the safety, convenience and quickness in supplying oil to vehicles are realized.

Owner:NANJING TECH UNIV

Contact device for cone ring transmission

InactiveCN101131200BSmall pressing forceConvenient oil supplyGearing controlFriction gearingsEngineeringMechanical press

Owner:GETRAG FORD TRANSMISSIONS GMBH

A kind of submersible vehicle software oil bag

InactiveCN102951277BImprove maneuverabilityHigh strengthUnderwater vesselsUnderwater equipmentFuel tankFuel oil

The invention relates to a soft oil storage device applied in an underwater vehicle, and particularly relates to a soft oil bag of an underwater vehicle. A bag wall is made of a polyurethane material. The bag wall is fixed on the wall of a cabin of the underwater vehicle by three sealed oil nozzle bolts to ensure the sealing of the wall of the cabin, and is fixed in the oil cabin by a plurality of hangers arranged on bag wall hanger holders. The ideal original state of the oil bag is the vacuum state, the bag walls are pasted together, and fuel oil is injected to the oil bag by an oil injection pump through an oil injection pipe and a sealing oil nozzle at an oil injection port. Along with the injection of the fuel oil, the oil bag is gradually filled. If the oil bag is initially provided with a certain amount of air, the air is exhausted by a sealing oil nozzle at an air exhaust port and an air exhaust pipe along with the injection of the fuel oil. When the fuel oil is required to be used, the fuel oil enters into a daily fuel oil tank through a sealing oil nozzle at an oil supply port and an oil supply pipe. The air bag is gradually shriveled along with the consumption of the fuel oil, and water is replenished into the cabin at any time, so that the function of not changing weight and gravity center parameters along with the fuel consumption of the underwater vehicle can be realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Oil supply detection device for engine of lifeboat of ship

PendingCN114046216ANormal oil supplyReduce pressureLiquid fuel feedersPump installationsSuction forceMarine engineering

The invention discloses an oil supply detection device for an engine of a lifeboat of a ship. The oil supply detection device comprises a columnar oil supply tank, the oil supply tank is of a hollow structure, the upper end of the oil supply tank communicates with an oil inlet pipe and an oil conveying pipe, and the lower end of the oil inlet pipe and the lower end of the oil conveying pipe are each provided with a one-way valve; the one-way valve at the oil inlet pipe allows liquid to flow into the oil supply tank from the oil inlet pipe in a one-way mode, the one-way valve at the oil conveying pipe allows liquid to flow into the oil inlet pipe from the oil supply tank in a one-way mode, the oil inlet pipe is communicated with an external oil tank, and the oil conveying pipe is communicated with the oil inlet end of a ship engine. The oil supply detection device has the advantages that when the oil pressure of the oil inlet end of an engine is low and normal oil supply cannot be met, the two baffles get close to each other and do not seal the oil supply pipe, the lower ring body floats upwards due to the fact that the density of the lower ring body is far smaller than that of water, and the magnetic ring moves synchronously along with the lower ring body in the floating process and drives the oil supply piston to move upwards through magnetic attraction force; oil in the oil supply tank is extruded to enter the oil inlet end of the engine through the oil supply pipe, and normal oil supply of the engine is guaranteed.

Owner:张雅楠

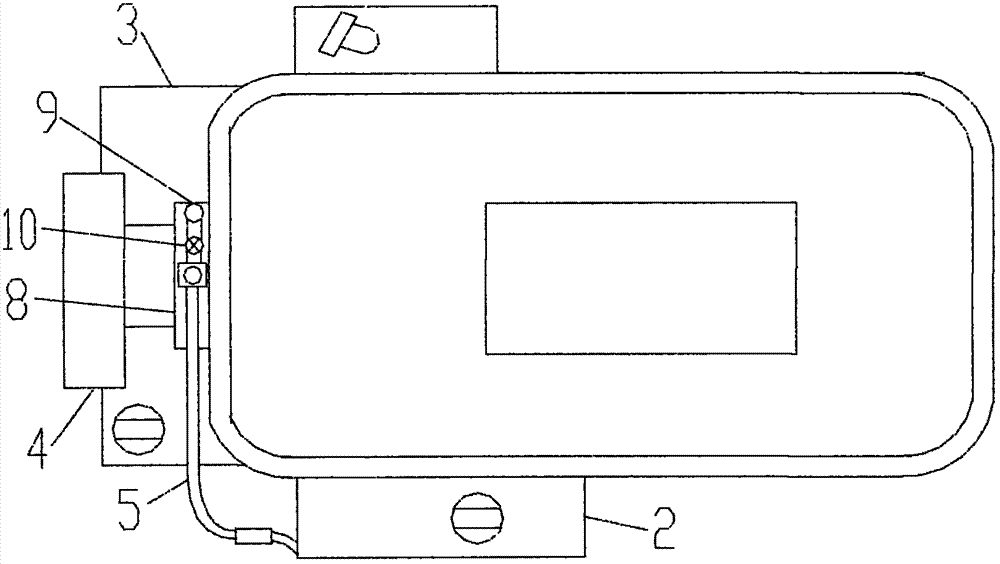

A multifunctional oil supply system for automobiles

InactiveCN106611458AGood fuel supplyEasy to useLiquid transferring devicesApparatus for dispensing fluids/granular materialsWireless transmissionSounds device

The invention relates to a multifunctional oil supply system for automobiles. The system comprises an oil storage system; an oil storage device is installed in the oil storage system; the upper portion of the oil storage device is provided with an oil supply port isolation sealing device; the left side of the upper portion of the oil storage system is provided with an intelligent switch system; the left side and the right side of the oil storage system are provided with a left supporting system and a right supporting system respectively; the upper portion of the right supporting system is provided with a movable link system; the upper portion of the movable link system is provided with a cover plate in a hinged manner; the middle position of the lower portion of the cover plate is provided with an electromagnetic switch; the upper portion and the lower portion of the left supporting system are provided with a sound transmission system and a sounding device; the right side of the left supporting system is provided with a wireless transmission system; the right side of the wireless transmission system is provided with an oil card system. The system can effectively improves an oil supply effect, facilitates oil supply to vehicles and is convenient to use.

Owner:重庆昶熙机械有限公司

Oil supply device

InactiveCN1981146AConvenient oil supplyMechanical actuated clutchesGear lubrication/coolingEngineeringOil supply

The invention relates to an oil supply device for a vehicle transmission (2) with: toothed wheels mounted on shafts; bearing arrangements inside of which toothed wheels and shafts are rotationally mounted, and; synchronizing devices (10), which are moved into the desired shifting positions via gear shift rods and gear shift forks by actuating a gear shift lever. One shaft (4) has an axially extending central hole (6) and at least one cross hole (8) for supplying oil. The oil supply device has holes (14) in a synchronizing body (12) of the synchronizing device (10), and a fixing plate (16) with a sickle-shaped cavity (18).

Owner:ZF FRIEDRICHSHAFEN AG

Elevator guide rail oilcan

InactiveCN101870428BExtended service lifeConvenient oil supplyElevatorsEngineeringMechanical engineering

The invention relates to a lubricating technology of an elevator guide rail, in particular to an elevator guide rail oilcan which has lightness, flexible installation and convenient oiling. The elevator guide rail oilcan comprises an oilcan body and an oilcan cover and is characterized in that the upper end of the oilcan body is designed into a '7'-shaped bulge; the middle part of the bulge is provided with an elevator guide rail containing cavity which has the same shape as the section of the elevator guide rail; the two ring surfaces of the bulge are provided with oil-supplying grooves; oil-returning grooves are arranged below the two side edges of the elevator guide rail containing cavity; the upper part of the oilcan body is provided with the oilcan cover; an oil absorbing device is arranged above the oil-supplying groove which is tightly attached with the bulge; the oil absorbing device absorbs lubricating oil in the oilcan body to the position of the elevator guide rail containing cavity; and an oil absorbing belt arranged on the oil absorbing device is used for oiling and lubricating on the elevator guide rail. The oilcan is fixed on an elevator cab guide shoe; a cotton-strip oil absorbing belt in an elevator guide rail notch is contacted with the elevator guide rail; and when the elevator cab runs, the oil absorbing belt oils the lubricating oil on the guide rail continuously and automatically.

Owner:周伟立

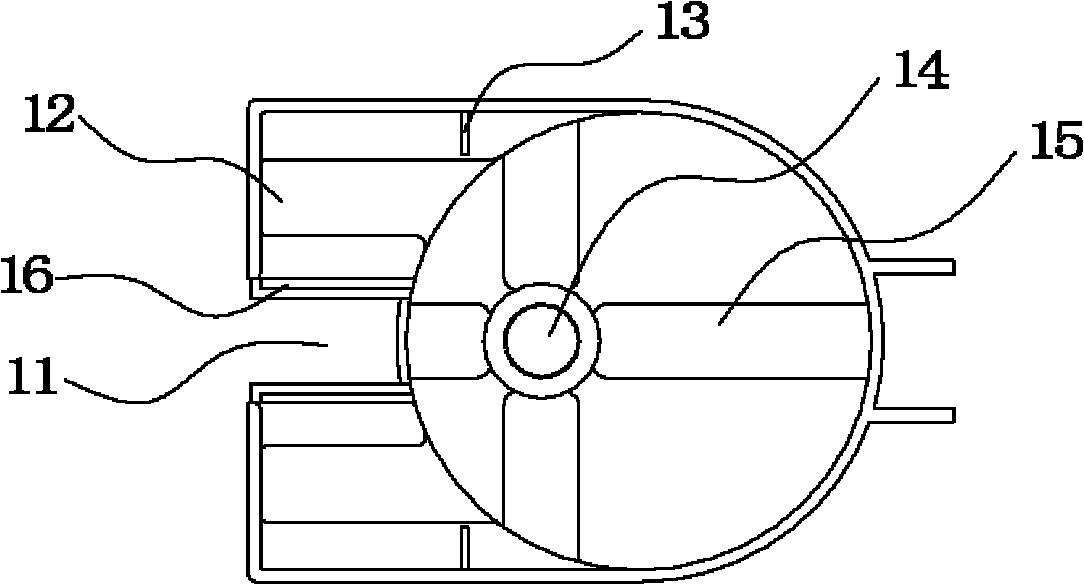

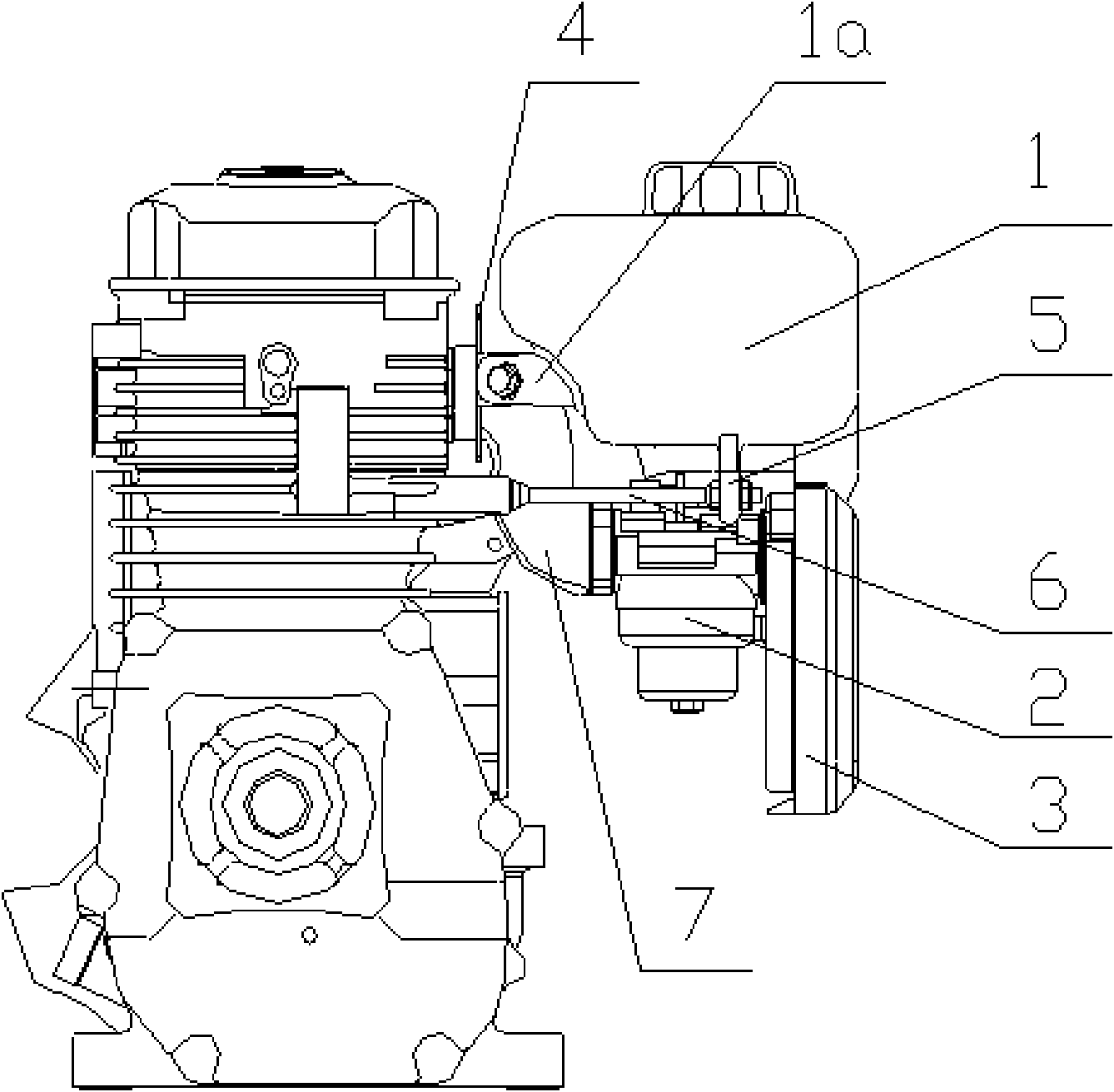

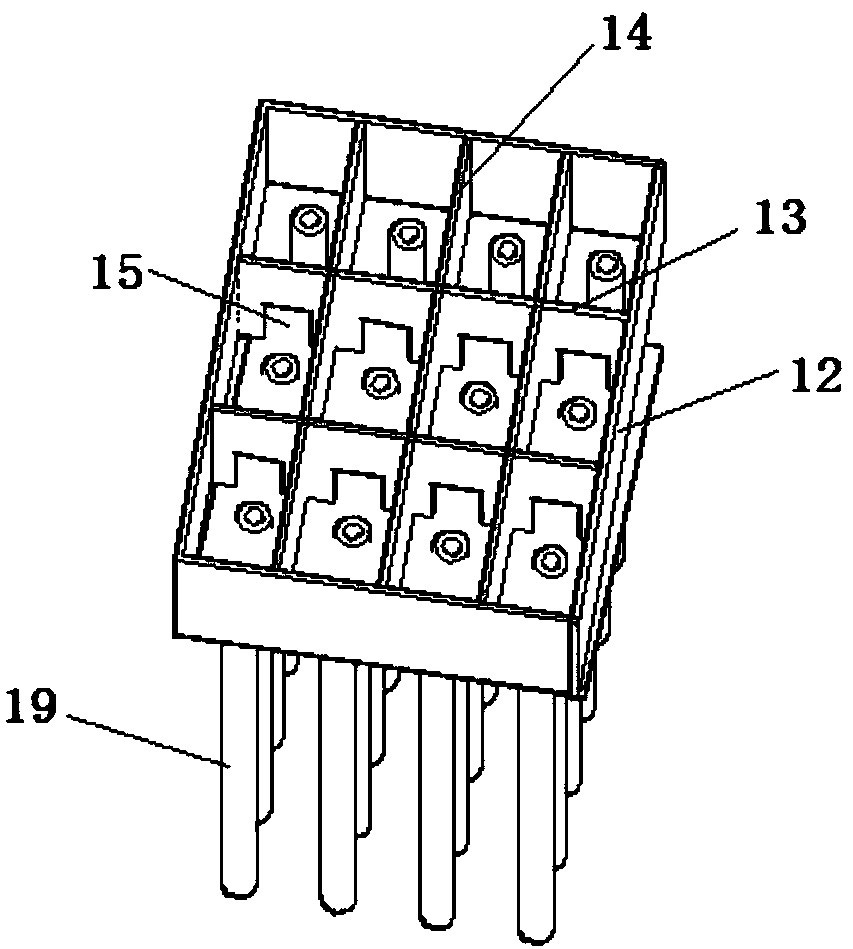

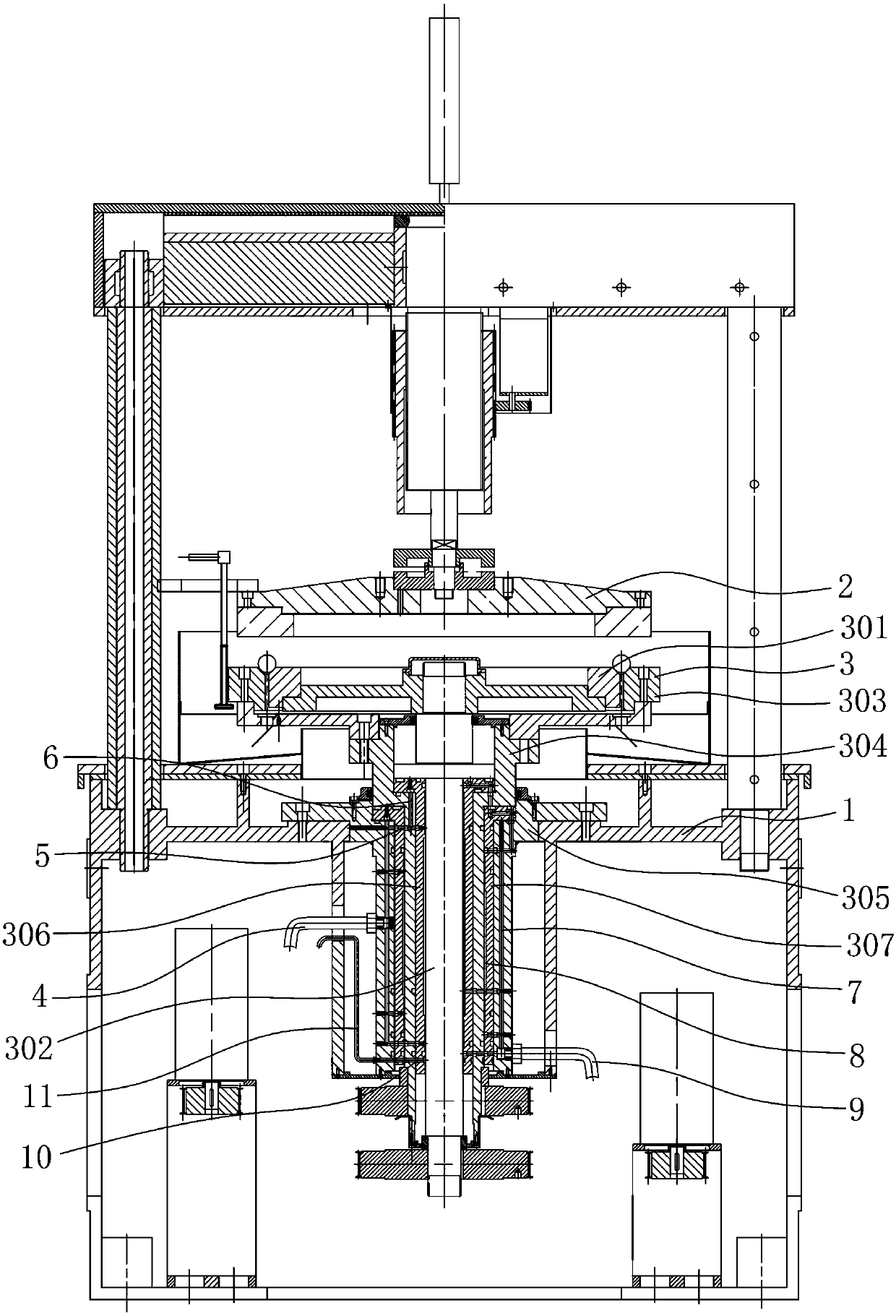

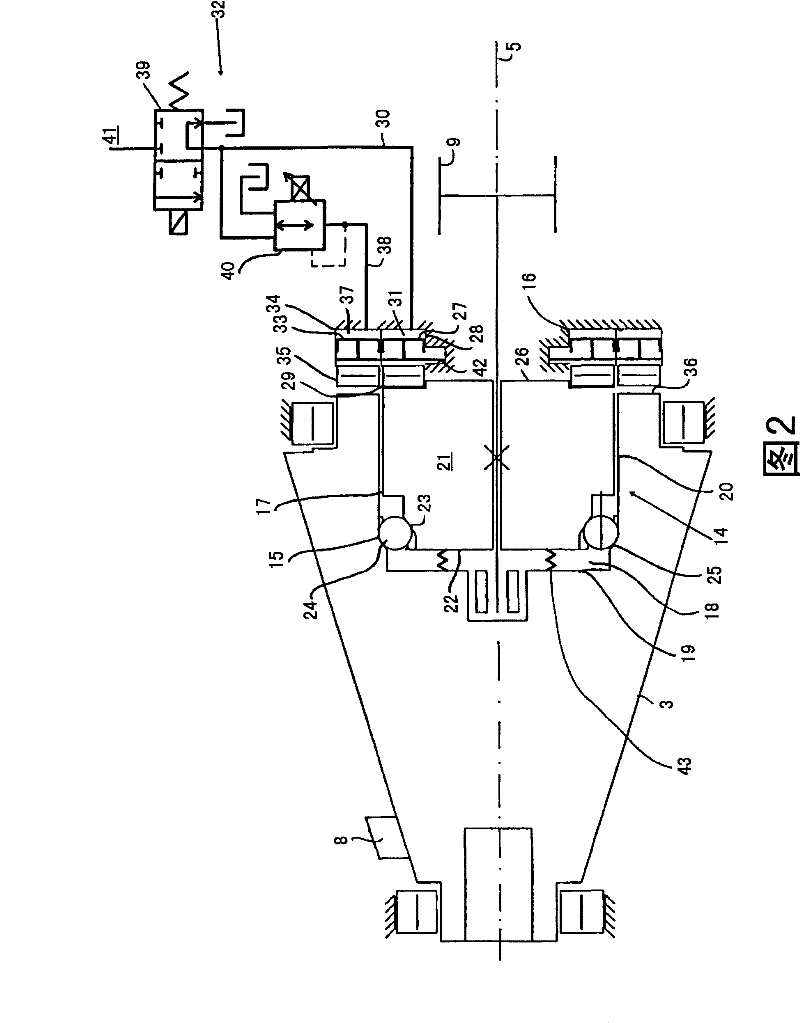

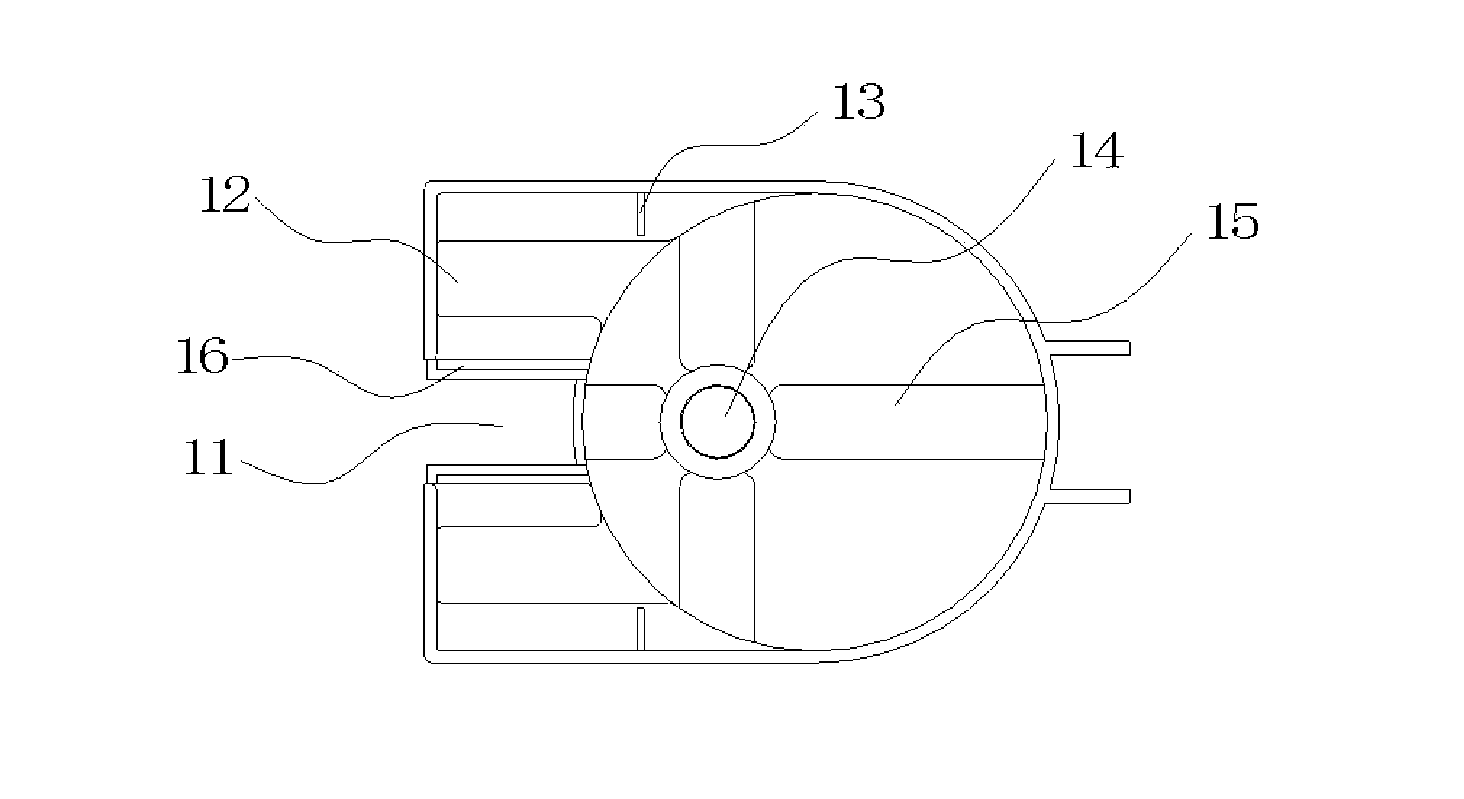

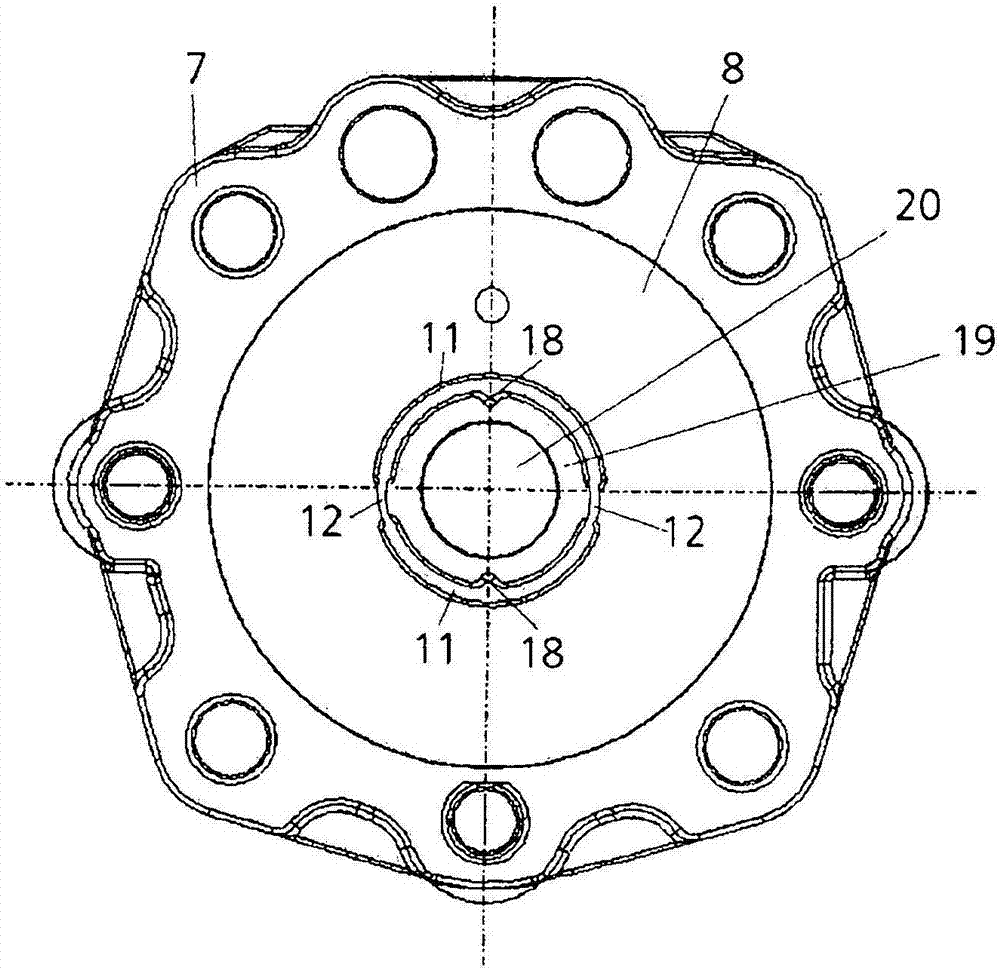

positive displacement pump

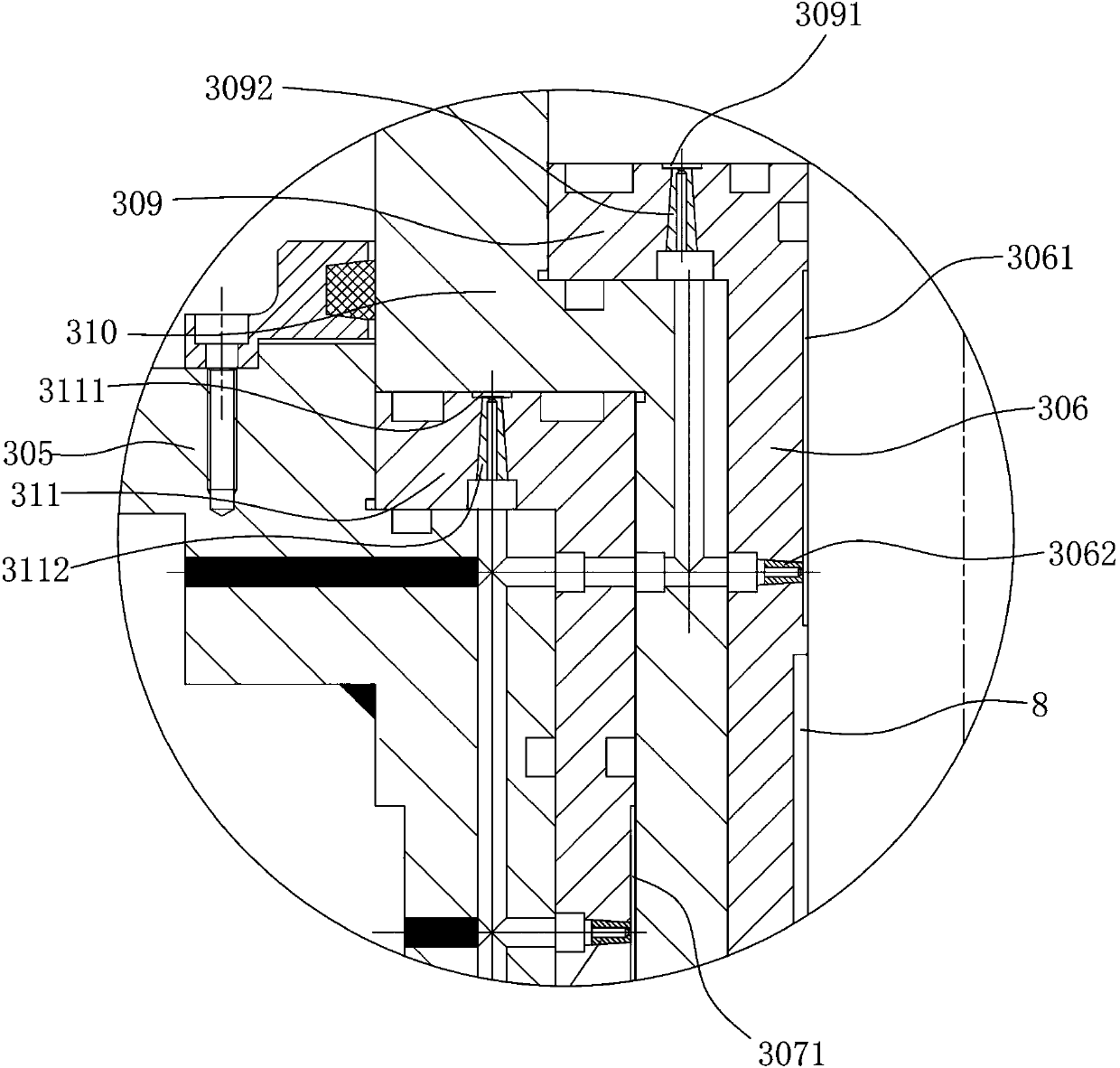

ActiveCN103842619BAvoid crackingConvenient oil supplyRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The invention relates to a displacement pump for delivering pressure medium to a load, in particular to a power steering system for a motor vehicle. A pump unit (2) comprising a rotor (3), a cam ring (4) and working slides (5) is arranged inside the housing (1), which is axially divided on one side by a The lid (7) is closed. Formed between the cam ring (4) and the rotor (3) are working chambers (6) separated by working slides (5), which are delimited in the axial direction by a control disk (9). The kidney-shaped supply channels ( 10 , 11 ) for supplying the working slide ( 5 ) and the working chamber ( 6 ) with oil are formed in the end face of the control disk ( 9 ) facing the rotor ( 3 ). There are annular spokes ( 19 ) in the kidney-shaped supply channels ( 10 , 11 ) and in the through-hole ( 20 ) for the drive shaft ( 13 ). At least one of the kidney-shaped supply channels (10, 11) is provided with at least one oil groove (18). The at least one oil groove (18) is arranged to protrude at least partially into the spoke (19).

Owner:PUMP TECH SOLUTIONS PS GMBH

Main shaft group on vertical shaft impact type crusher

InactiveCN104728254AGuaranteed tightnessImprove enduranceShaftsBearing unit rigid supportAgricultural engineeringCrusher

The invention relates to the field of mine equipment and particularly relates to a main shaft group on a vertical shaft impact type crusher. The main shaft group on the vertical shaft impact type crusher comprises a main shaft box, and a main shaft for positioning and mounting the main shaft box. The main shaft group has the advantages of good main shaft stability, good sealing effect and reasonable sliding structure.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

Improved vacuum pump

InactiveCN103244417AConvenient oil supplySimple structurePumpsRotary/oscillating piston pump componentsOil transportationVacuum pump

The invention discloses an improved vacuum pump, comprising a pump body. The improved vacuum pump is characterized in that the pump body is fixed on a machine base; a first-level rotor is arranged in the pump body; one end of the first-level rotor is connected with a motor arranged on one end of the pump body; the motor is also fixed on the machine base; one end of the first-level rotor, which is far away from the motor, is provided with a first-level top cover; the top of the first-level rotor is connected with the bottom of an oil transportation pipe penetrating through the first-level top cover; the top of the oil transportation pipe is arranged on the top of the pump body; the other end of the first-level rotor is connected with a second-level rotor; one end of the second-level rotor, which is far away from the motor, is provided with a second-level top cover; the outer side of the pump body, which is far away from the motor, is provided with an end cover matched with the pump body; the pump body is provided with an oil transportation end cover on the top position of the oil transportation pipe; the oil transportation end cover is provided with an end cover handle; and a buffer cushion is arranged between the pump body and the machine base. The improved vacuum pump has the advantages of simple structure, reliable and stable vacuum performance, convenience for rotor oil supply, low cost, high work efficiency and convenience for installation, disassembly and maintenance.

Owner:NANTONG LONGYING VACUUM PUMP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com