Elevator guide rail oilcan

A technology of elevator guide rails and oil pots, applied in the field of elevator guide rail lubrication, can solve the problems of high maintenance, inconvenient, complex automatic lubrication structure and cost, etc., and achieve the effects of long service life, reasonable structure design and excellent oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

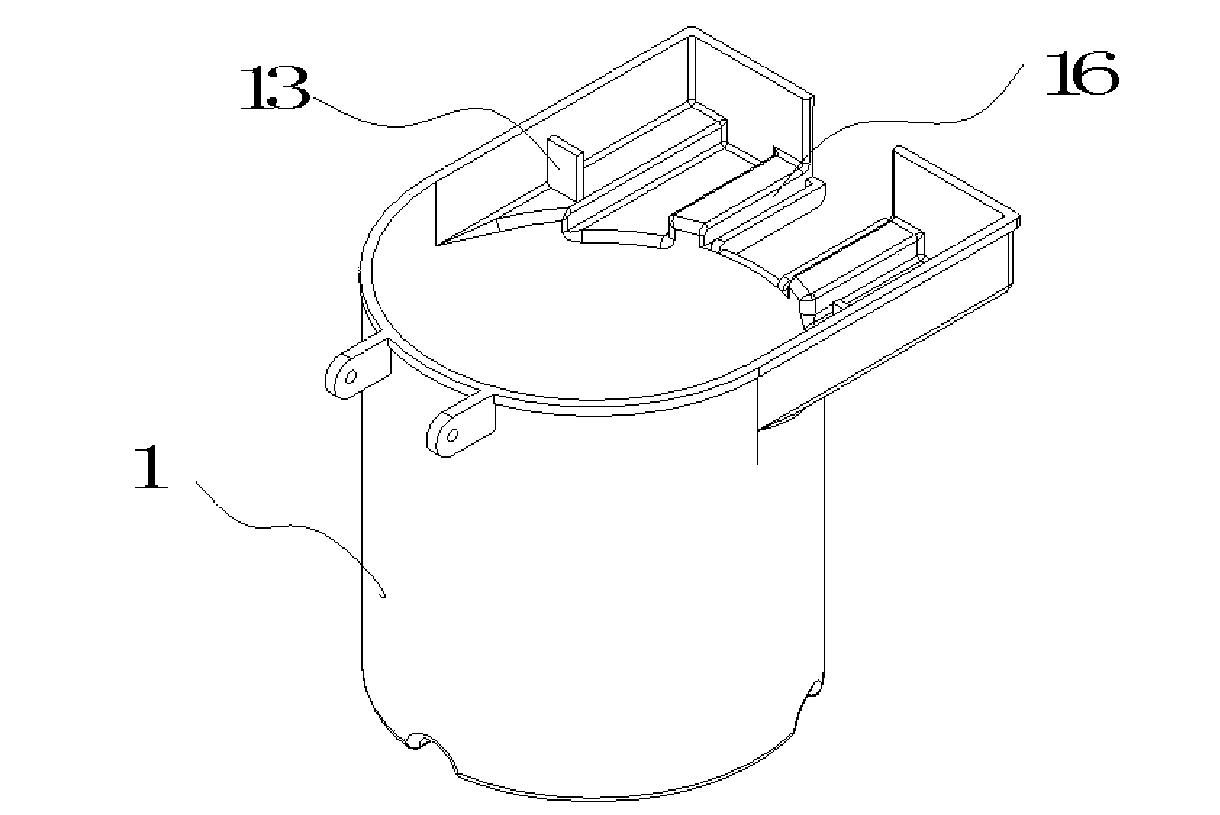

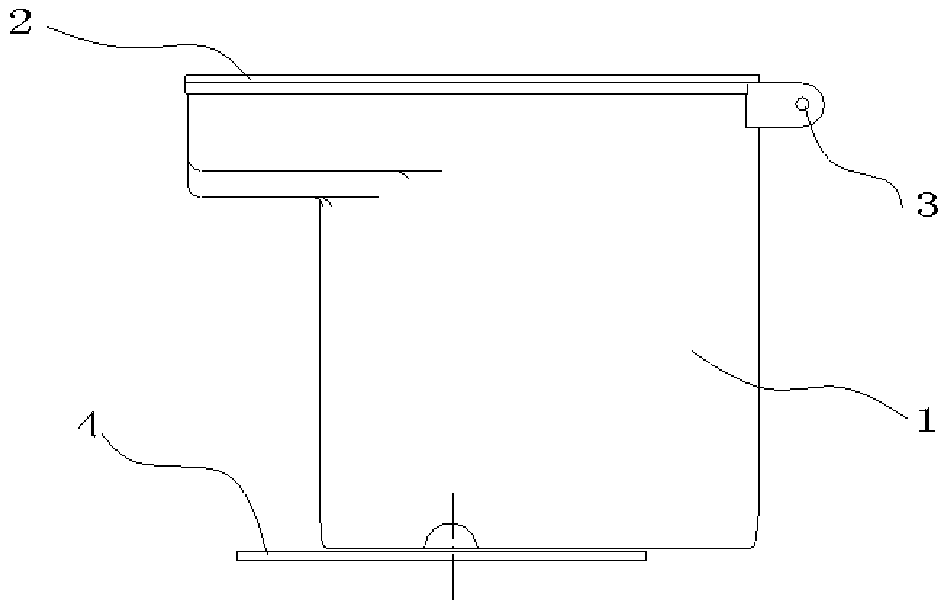

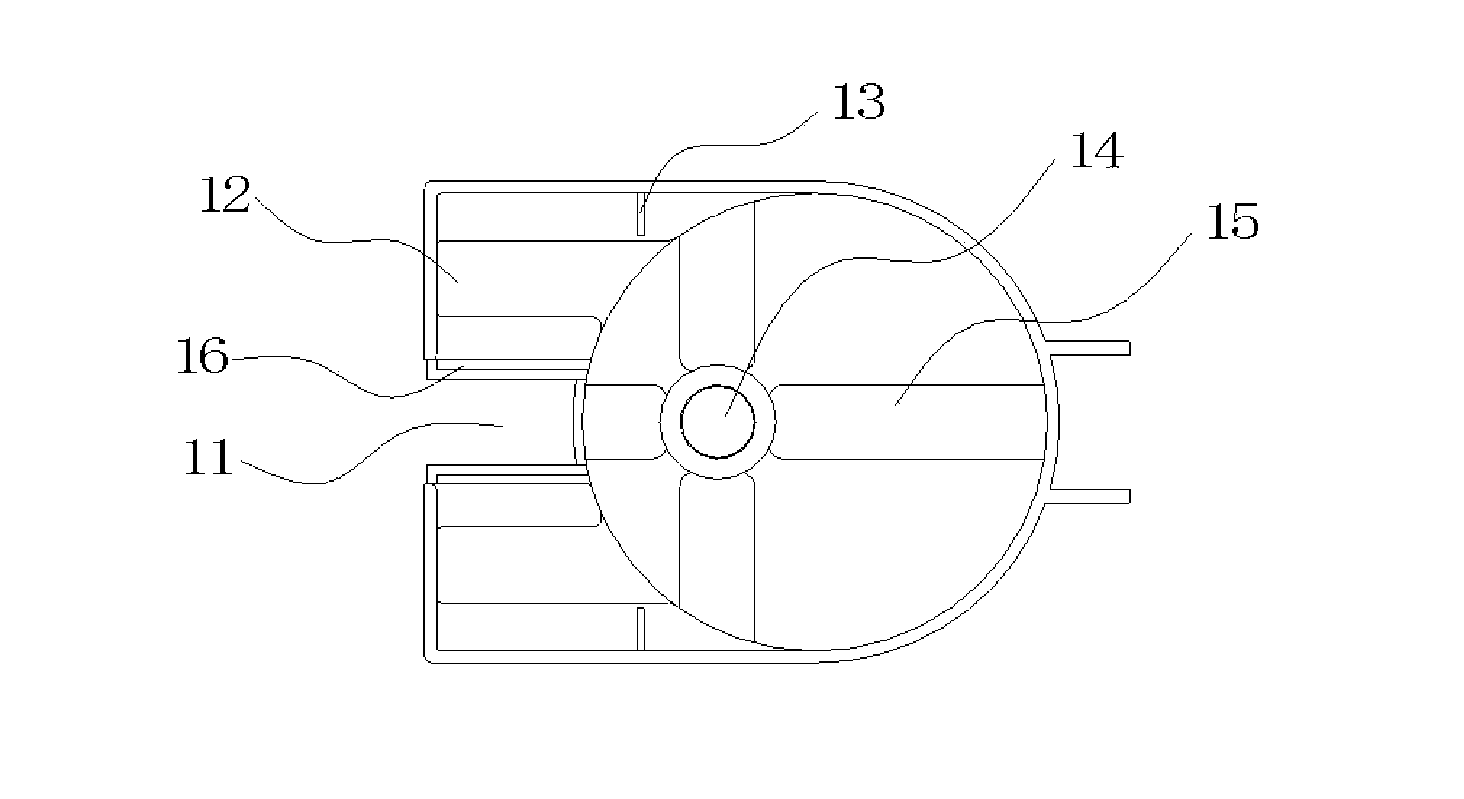

[0028] see figure 1 and image 3 , this embodiment includes a pot body 1 and a pot cover 2. The pot body 1 is a cylinder, and the upper part of the pot body 1 is made into a "7"-shaped protruding shape, and an elevator cavity 11 is set in the middle of the protruding part of the upper part. The protruding parts on both sides form an accommodating space with the pot lid, and the protruding parts on both sides are provided with an oil supply tank 12, and the both sides of the elevator cavity 11 are provided with an oil return tank 16, and the height of the oil return tank 16 is generally higher than that of the supply tank. The groove bottom of oil groove 12 is slightly lower, and protruding part and kettle body 1 top are the pot cover 2 of unity.

[0029] The oil supply groove 12 and the oil return gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com