Fuel supply structure for general gasoline engines

A general-purpose gasoline engine and fuel supply technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of reduced reliability of the oil supply system, interruption of oil supply, and increased cost of the general gasoline engine. , to avoid unreliability, the effect of stable oil supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

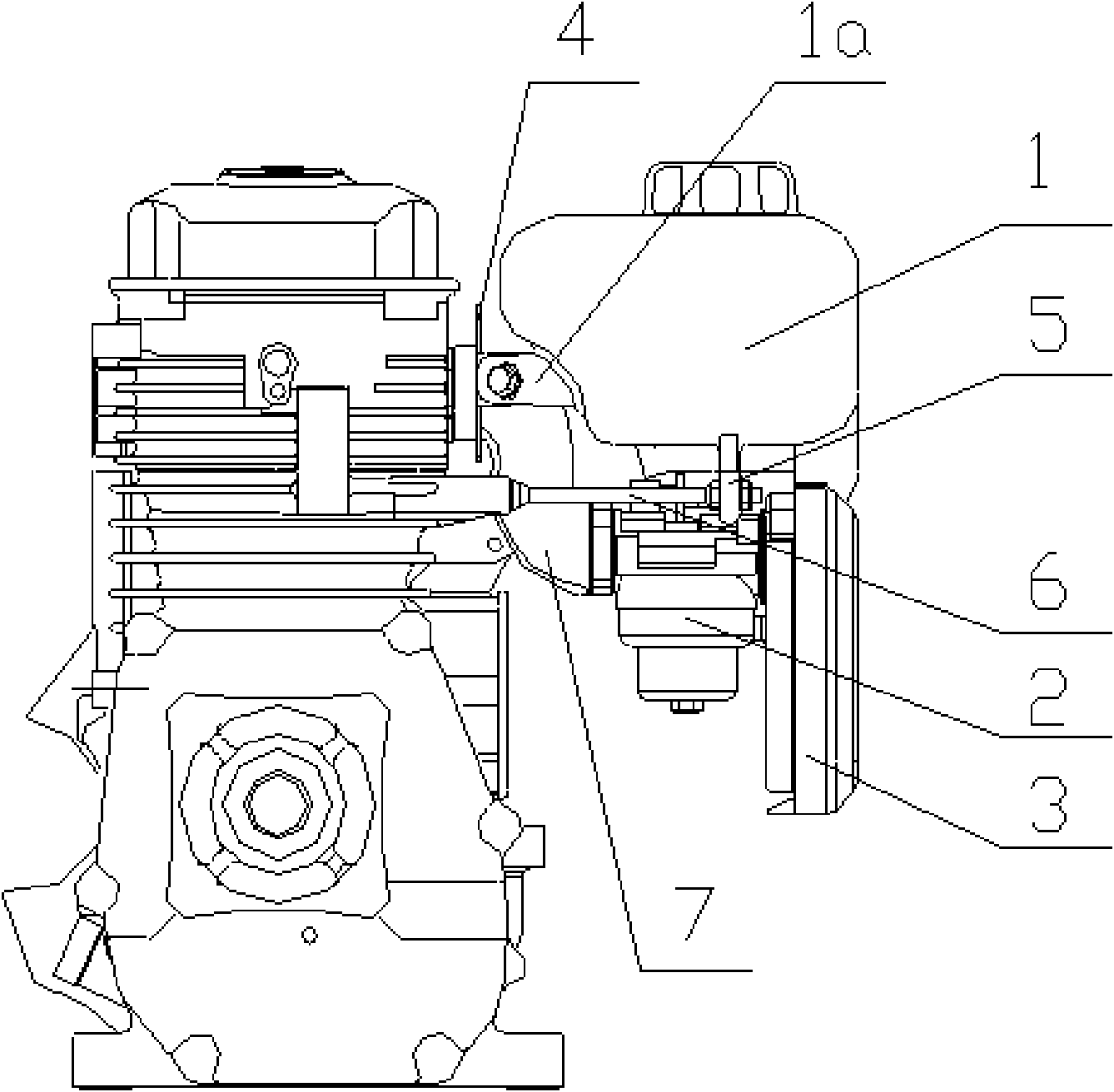

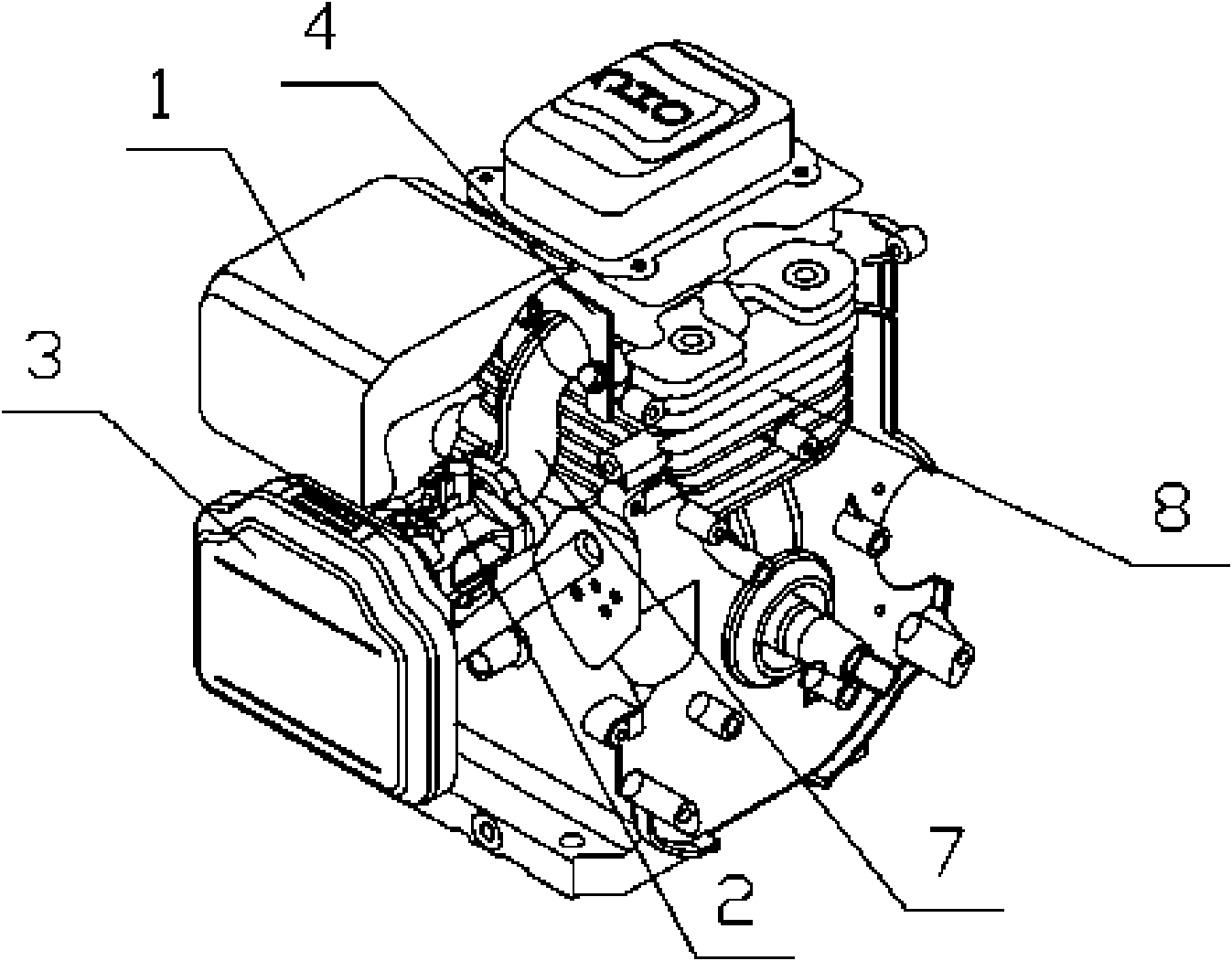

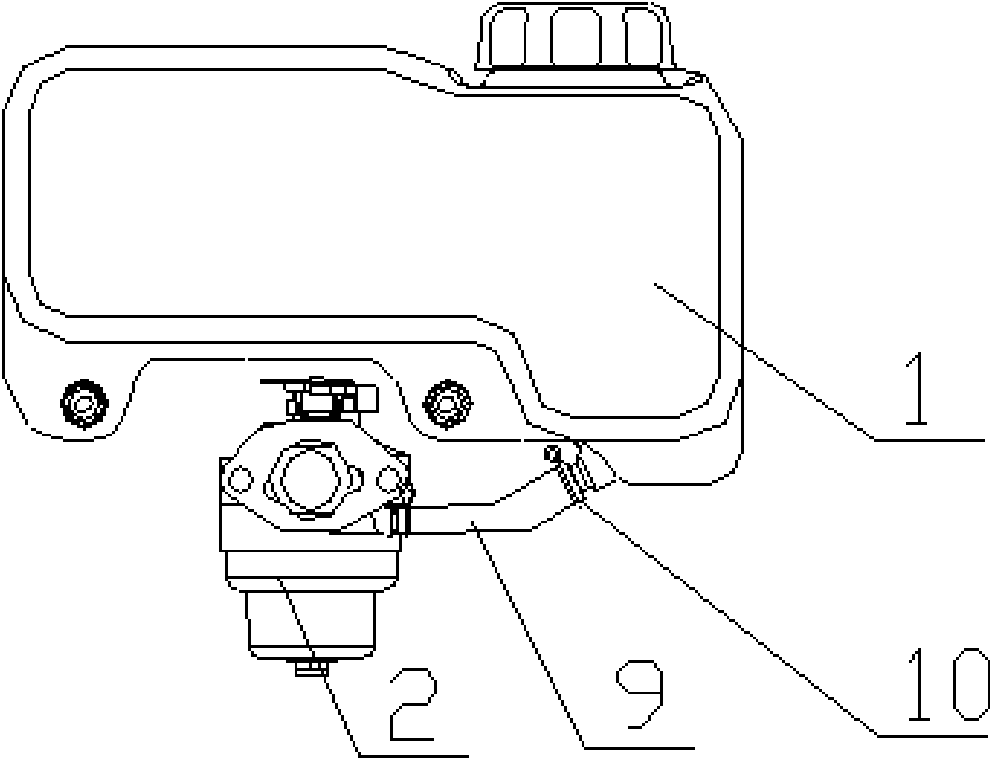

[0015] refer to figure 1 , figure 2 , the fuel supply structure of a general gasoline engine includes a fuel tank 1, a carburetor 2, and an air filter 3. The fuel tank, carburetor, and air filter are all located on the engine side, and the fuel provided by the fuel tank 1 and the air filter 3 provide The fresh air is mixed in the carburetor 2 to form a mixed gas, which is then sent into the engine cylinder to burn and do work to form power. The side of the fuel tank 1 is integrally connected with a fuel tank lug 1a, and the fuel tank lug 1a is provided with a mounting hole. One side of the fuel tank is installed next to the cylinder head 8 through a fuel tank bracket. The fuel tank bracket includes a first bracket 4 and a second bracket 5. The first bracket 4 is fixedly connected to the cylinder head through bolts, and the side of the fuel tank passes through the fuel tank support through bolts. The mounting hole of the ear 1a is tightly connected with the mounting hole on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com