Oil supply device

A technology of oil supply device and synchronizing device, which is applied in the directions of transmission parts, gear lubrication/cooling, clutch, etc., and can solve the problem of inability to supply oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

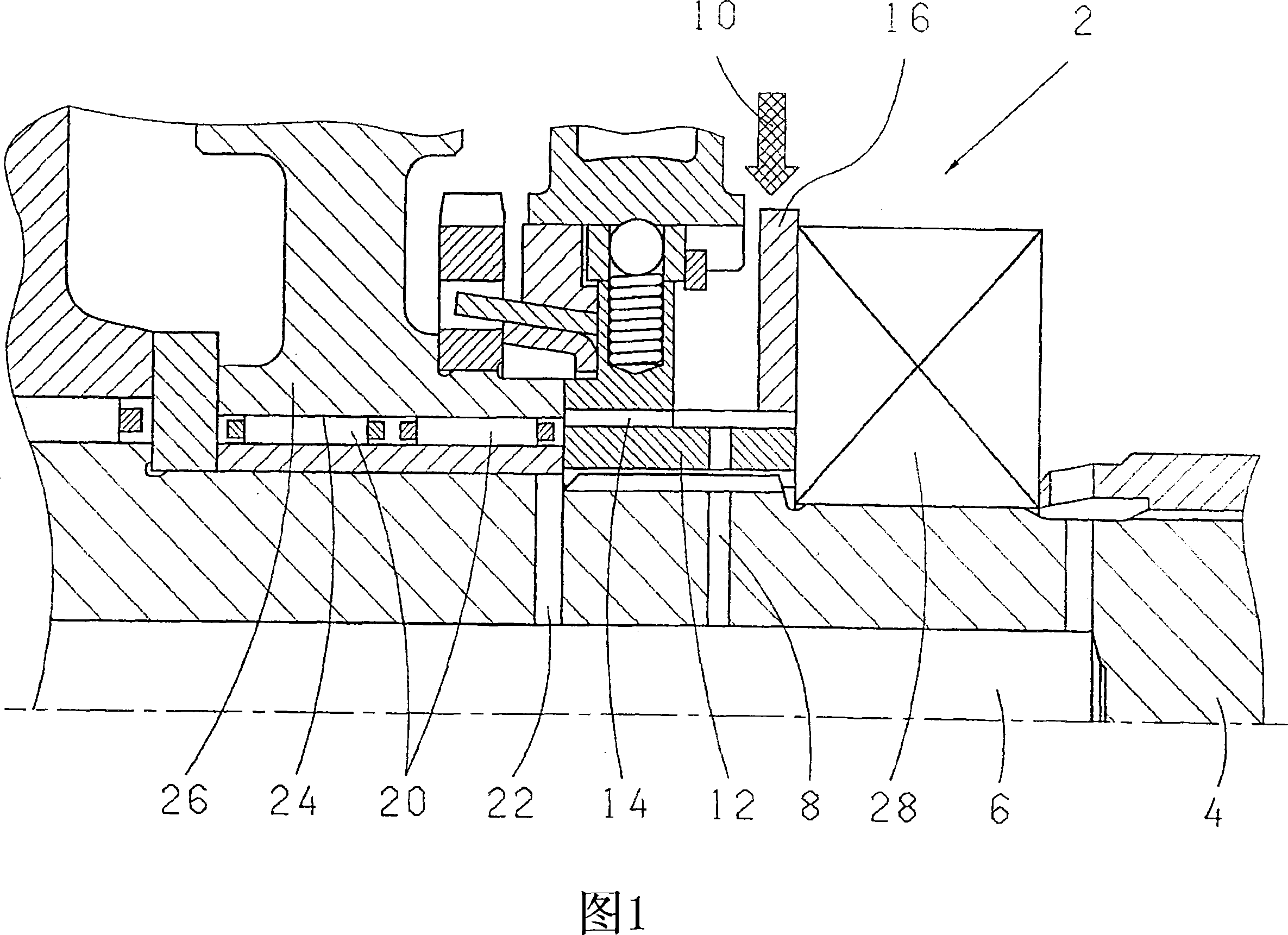

[0014] FIG. 1 shows a partial sectional view of a motor vehicle transmission 2 according to the invention having a shaft 4 with an axially central bore 6 . The oil enters the synchronizer 10 through the transverse bore 8 . The synchronizing body of the synchronizing device 10 has a bore 14 , through which and a fixing plate 16 with a sickle-shaped opening 18 , the volume of oil flowing in the rotational movement and in the direction of rotation is reduced between the synchronizing device 10 and the bearing 28 . Part of the volume flow of the oil flows via the central bore 6 on the shaft 4 , the transverse bore 8 and the bore 14 in the synchronizing body 12 to the parts to be supplied with oil, here for example the bearing 20 . The remaining oil can escape radially as a loss between the synchronizer 10 and the bearing 20 . Additional oil can be supplied to the running surface 24 of the gear wheel 26 via the transverse bore 22 .

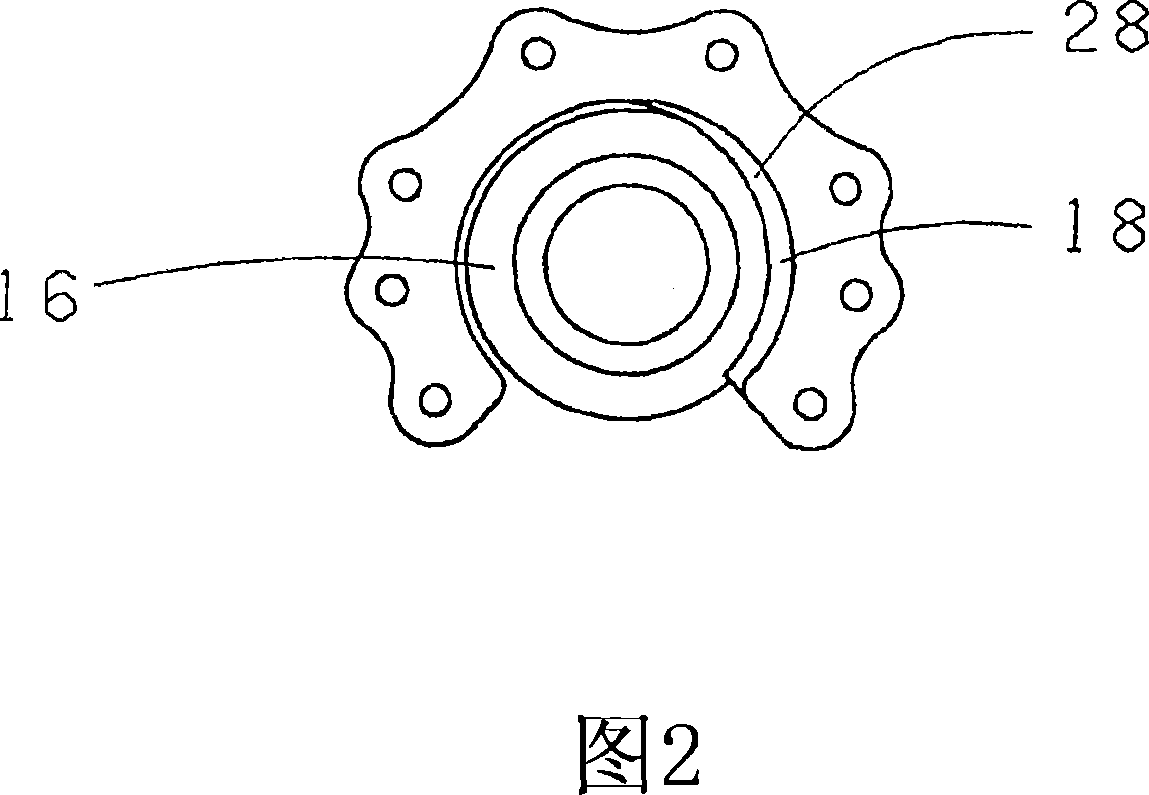

[0015] FIG. 2 shows an embodiment of a housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com