Main shaft group on vertical shaft impact type crusher

A vertical shaft impact and crushing machine technology, applied in the direction of the shaft and bearing, the rigid support of the bearing components, the shaft, etc., can solve the problems of hidden safety hazards, insufficient stability of the main shaft, inconvenient oil supply, etc., to ensure stability and internal oil circuit Reasonable setting, convenient oil supply and return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

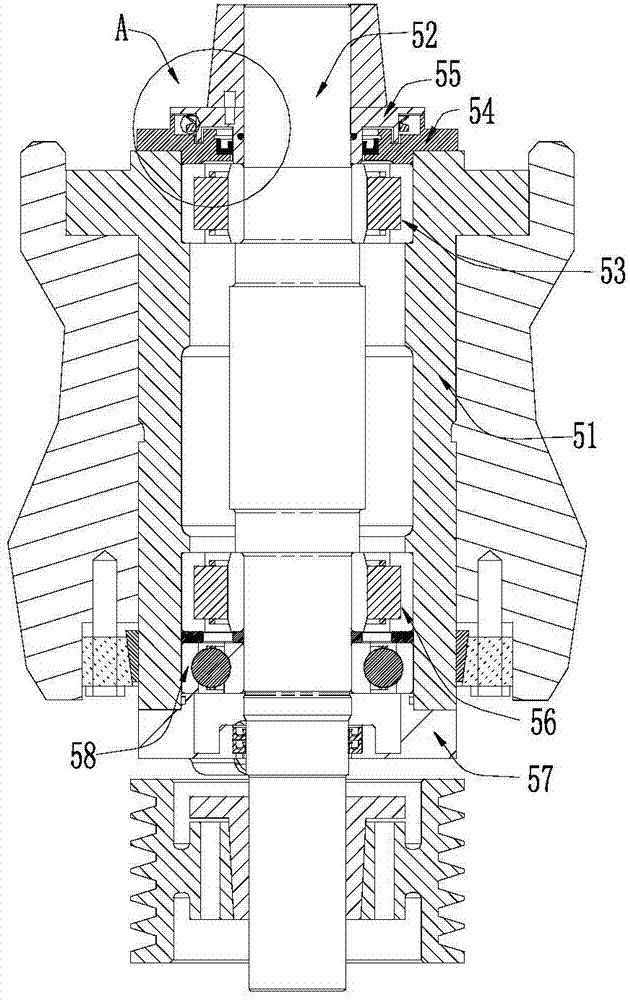

[0015] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

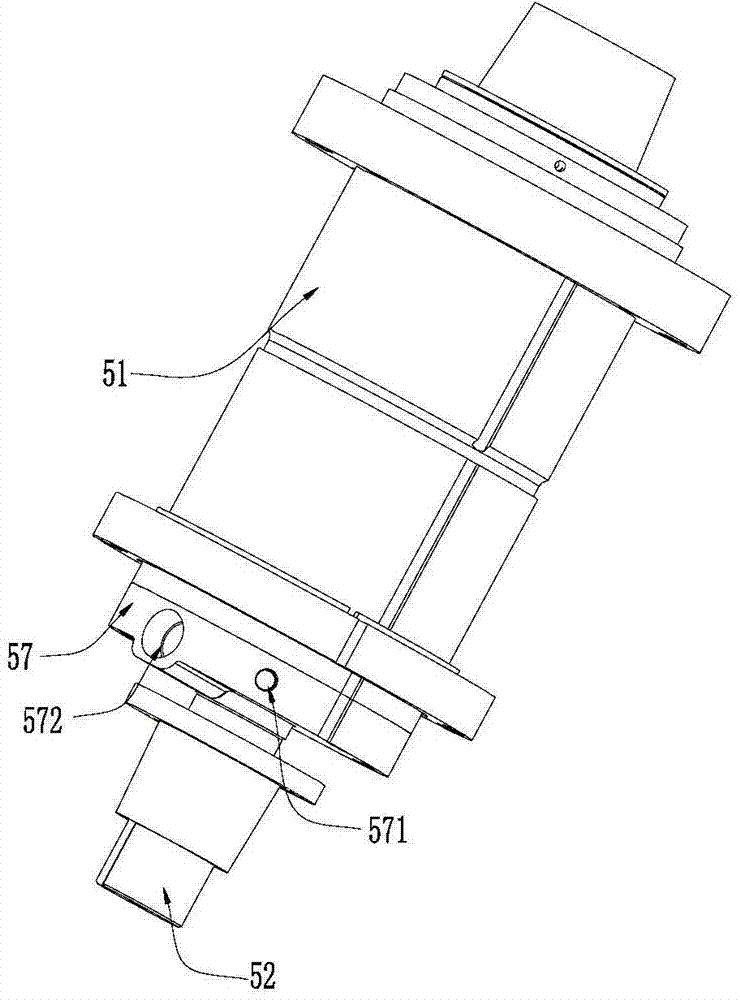

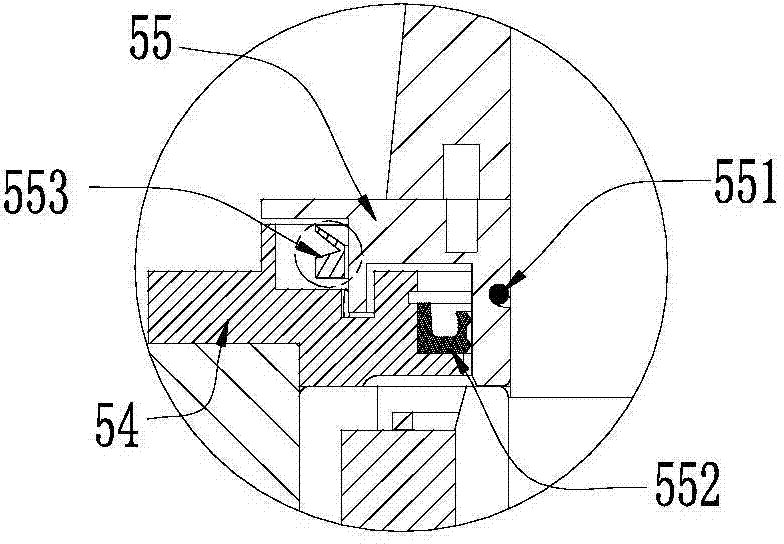

[0016] Such as Figure 1~Figure 4 The shown main shaft group on a vertical shaft impact crusher includes a main shaft box 51 and a main shaft 52 positioned and installed in the main shaft box. The inner upper end of the spindle box 51 is provided with an upper roller bearing 53 positioned through an upper bearing end cover 54. The outer end of the upper bearing end cover 54 is closely matched with the main shaft box 51, and the inner end of the upper bearing end cover 54 is in contact with the main shaft. 52 is provided with an upper seal disc 55; an O-ring 551 is provided between the upper seal disc 55 and the main shaft 52, and a lip seal ring 552 and Vd are provided between the upper seal disc 55 and the upper bearing end cover 54. Sealing ring 553; three kinds of sealing rings are used to ensure the bearing sealing effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com