Refrigerator compressor with filter

A refrigerator compressor and filter device technology, which is applied to mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as wear and shorten the service life of compressors, and achieves long service life, reduced damage, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

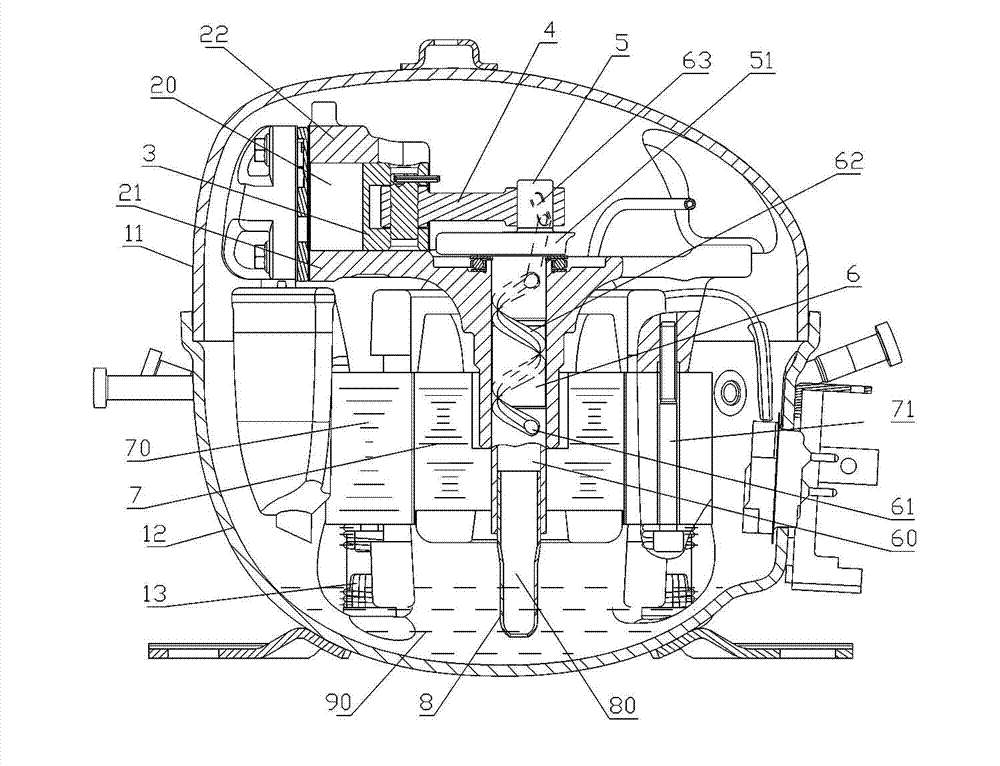

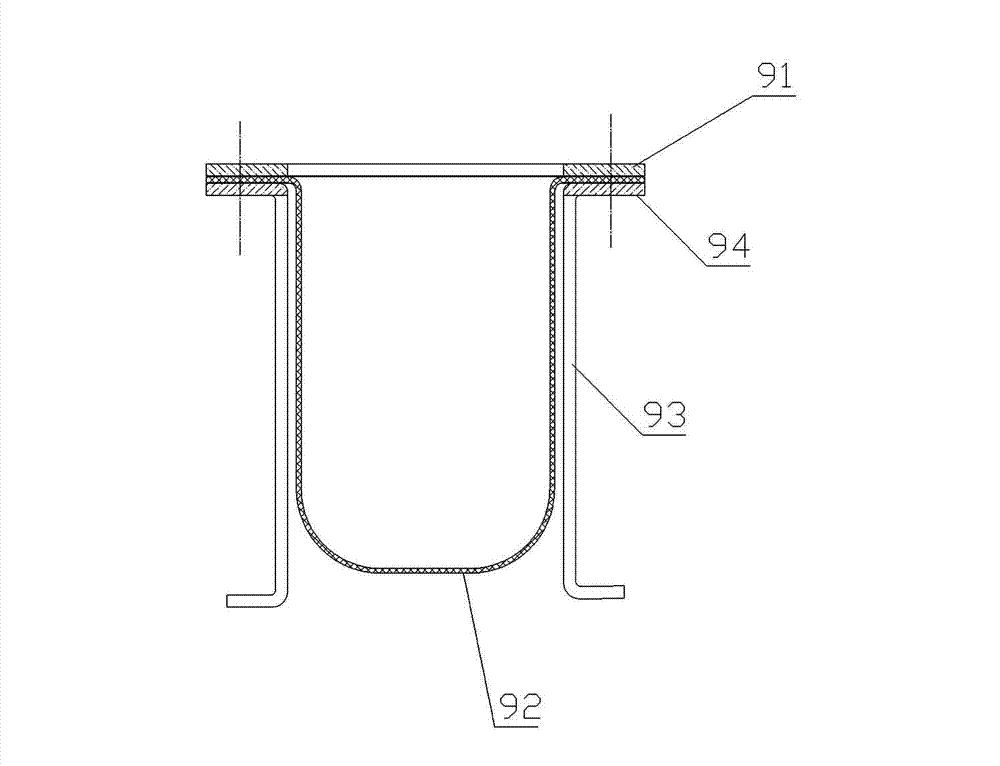

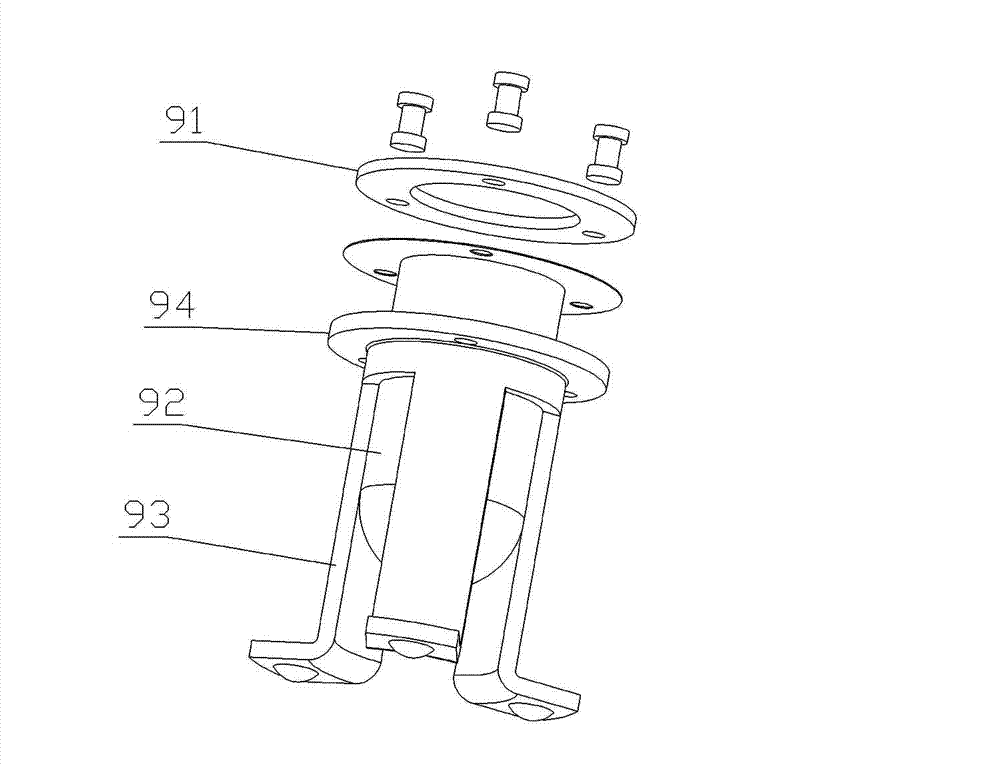

[0030] refer to figure 2 , image 3 and Figure 4 , a refrigerator compressor with a filter device, including a housing, a core and a core support structure, the housing is formed by sealing the upper shell 11 and the lower shell 12, the core includes a bracket 21, a cylinder block 22 , crankshaft, motor stator 70, rotor 7 and movement mounting bolts 71, the cylinder block 22 is connected to the bracket 21, the cylinder 20 of the cylinder block 22 has a built-in piston 3, and the motor stator 70 includes a stator core and a coil wound around the stator core. The stator winding, the stator core is fixedly connected to the bottom of the bracket 21 through the machine core mounting bolts 71, the middle part of the bracket 21 is provided with a shaft hole, the crankshaft includes a crankshaft part 5, a balance part 51 and a main shaft part 6, and the main shaft part 6 of the crankshaft passes through Through the shaft hole in the middle of the bracket 21, there is a bearing bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com