Environment-friendly paint

A technology of environmentally friendly paints and film-forming additives, applied in the field of paints and coatings, can solve the problems of affecting consumers' health, strong taste, etc., and achieve the effects of low production cost, fast drying, and good scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

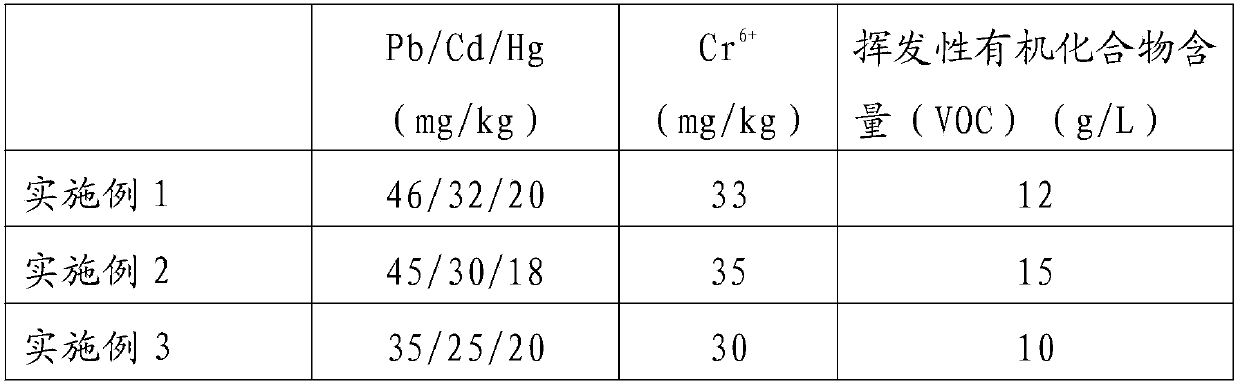

Examples

Embodiment 1

[0020] Embodiment 1 of the present invention provides a kind of environmental protection paint, mainly comprises the following raw materials, counted by weight: 8 parts of film-forming aids, 15 parts of cellulose, 20 parts of water, 7 parts of titanium dioxide, 3 parts of zinc oxide, 5 parts of aluminum silicate, 5 parts of kaolin, 0.7 parts of coupling agent, 0.5 parts of dispersing agent, 4 parts of defoamer, 3 parts of preservative, 1.5 parts of pH regulator, 30 parts of styrene-acrylic emulsion, 0.5 part of thickener , 1 part of polyvinyl alcohol, 0.5 part of sodium hexametaphosphate.

[0021] The cellulose is hydroxyethyl cellulose.

[0022] The film-forming aid is alcohol ester twelve.

[0023] The dispersant is a mixture of polyacrylic acid ammonium salt and polyacrylic acid sodium salt.

[0024] The coupling agent is KH550, the thickener is methylcellulose, the defoamer is polydimethylsiloxane, and the preservative is sorbic acid.

[0025] In addition, this embodime...

Embodiment 2

[0033] Embodiment 2 of the present invention provides a kind of environmental protection paint, mainly comprises the following raw materials, by weight parts: 12 parts of film-forming aids, 25 parts of cellulose, 30 parts of water, 9 parts of titanium dioxide, 5 parts of zinc oxide, 10 parts of aluminum silicate, 15 parts of kaolin, 2 parts of coupling agent, 6 parts of dispersant, 8 parts of defoamer, 7 parts of preservative, 2.5 parts of pH regulator, 40 parts of styrene-acrylic emulsion, 6 parts of thickener , 3 parts of polyvinyl alcohol, 2 parts of sodium hexametaphosphate.

[0034] The cellulose is hydroxyethyl cellulose.

[0035] The film-forming aid is alcohol ester twelve.

[0036] The dispersant is a mixture of polyacrylic acid ammonium salt and polyacrylic acid sodium salt.

[0037] The coupling agent is KH550, the thickener is methylcellulose, the defoamer is polydimethylsiloxane, and the preservative is sorbic acid.

[0038] In addition, this embodiment also pr...

Embodiment 3

[0046] Embodiment 3 of the present invention provides a kind of environmental protection paint, mainly comprises the following raw materials, counted by weight: 10 parts of film-forming aids, 20 parts of cellulose, 25 parts of water, 8 parts of titanium dioxide, 4 parts of zinc oxide, 7.5 parts of aluminum silicate, 10 parts of kaolin, 1.3 parts of coupling agent, 3.2 parts of dispersant, 6 parts of defoamer, 5 parts of preservative, 2 parts of pH regulator, 35 parts of styrene-acrylic emulsion, 3.2 parts of thickener , 2 parts of polyvinyl alcohol, 1.25 parts of sodium hexametaphosphate.

[0047] The cellulose is hydroxyethyl cellulose.

[0048] The film-forming aid is alcohol ester twelve.

[0049] The dispersant is a mixture of polyacrylic acid ammonium salt and polyacrylic acid sodium salt.

[0050] The coupling agent is KH550, the thickener is methylcellulose, the defoamer is polydimethylsiloxane, and the preservative is sorbic acid.

[0051] In addition, this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com