A pressure reducing valve control circuit and its control method

A technology of control circuit and control method, applied in engine control, carburetor, engine components, etc., can solve problems such as user misoperation, unstable engine performance, unstable engine operation, etc., to ensure stable operation and facilitate oil supply or the effect of air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

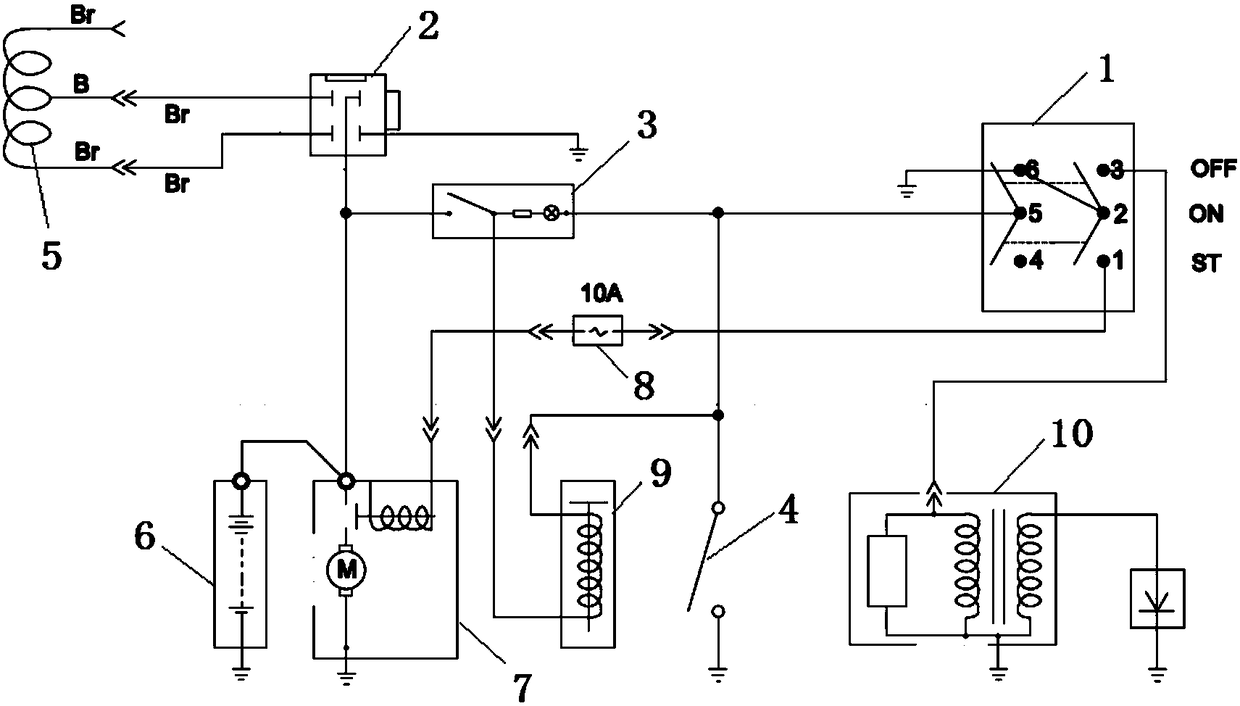

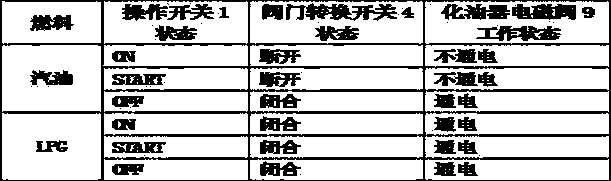

[0025] like figure 1 As shown, a pressure reducing valve control circuit includes an operation switch 1, a rectifier bridge 2, an energy saving switch 3, a valve changeover switch 4 and a charging coil 5, wherein the operation switch 1 is a switch with 6 ports, which can be specifically A switch with the model number KCD4-00-2060A-BR05 is used: including the first port, the second port, the third port, the fourth port, the fifth port and the sixth port, wherein the second port shown is connected to the sixth port , and grounded, the third port shown is connected to the flameout end of the generator high voltage pack 10, and the fifth port is connected to the third port of the energy-saving switch 3, the negative pole of the carburetor solenoid valve 9 and the valve changeover switch 4 respectively. The AC24V current output by the charging coil is rectified by the rectifier bridge 2 to charge the 12V storage battery 6. The storage battery 6 is connected to the starter motor rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com