Segment crane and shield tunneling machine

A segment and crane technology, applied in mechanical equipment, load hanging elements, wellbore lining, etc., can solve the problems affecting the working efficiency of the shield machine, downtime for maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

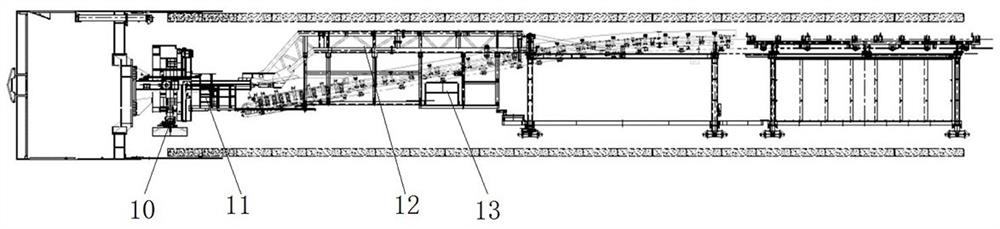

[0071] Such as Figure 1 to Figure 4 As shown, the shield machine in this embodiment includes a main beam 11, a main drive is arranged at the front of the main beam 11, and a shield body is arranged outside the main drive, and the main drive is used to drive the cutter head to rotate. A segment laying machine 10 is installed on the rear side, and the segment laying machine 10 is used to lay the segment in the tunnel to form a segment ring, and a segment crane is slidably installed on the equipment bridge 12 at the rear side of the main girder 11 The machine 13 is used for hoisting and transporting the segments on the marshalling train to the segment laying machine 10.

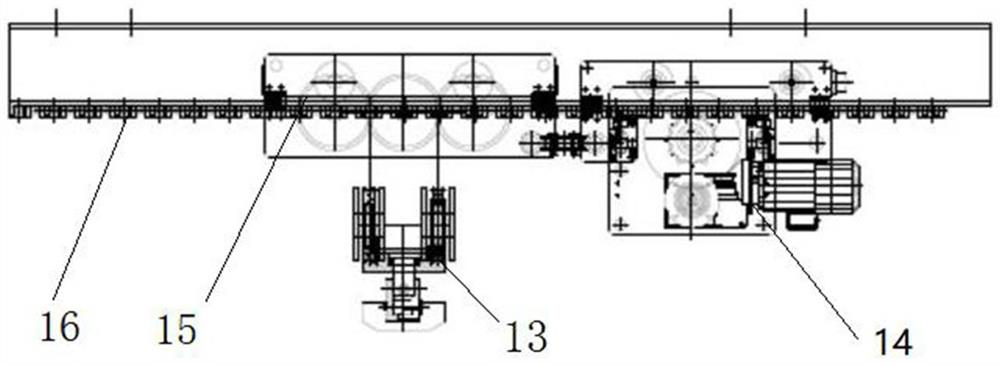

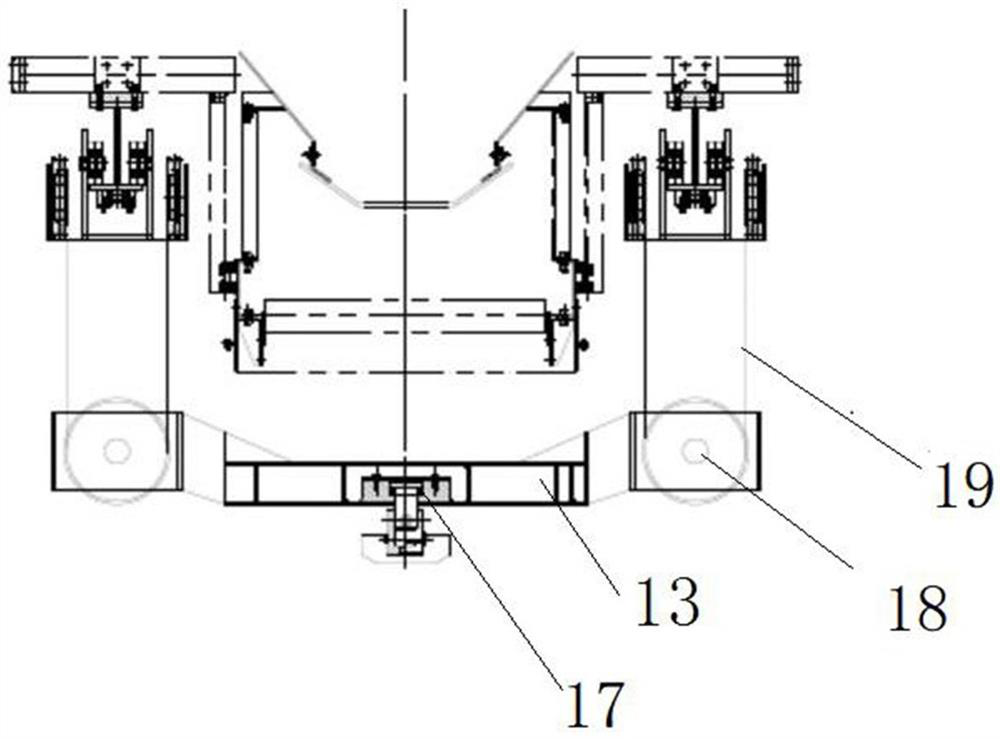

[0072] The equipment bridge 12 is provided with a track beam 16, and the track beam 16 is reciprocatingly equipped with a segment crane 13 along the front and rear direction. Two hydraulic cylinders 15 extending horizontally are arranged on the top, and the output ends of the two hydraulic cylinders 15 drive t...

specific Embodiment 2

[0093] The main difference between it and Embodiment 1 is that in Embodiment 1, the rodless cavity oil circuit and the rod cavity oil circuit of each hydraulic circuit have two branch oil circuits respectively, which can realize height and low speed control. In this embodiment, the rodless cavity oil circuit and the rod cavity oil circuit of each hydraulic circuit respectively have more than three branch oil circuits, correspondingly, more than three reversing valves can be configured to realize high, medium and low speed control.

[0094] Of course, in other embodiments, each hydraulic circuit can also only be provided with a reversing valve. At this time, no branch oil circuit is provided. At this time, although the control of different speeds cannot be realized, the synchronization of the two hydraulic cylinders can still be controlled. Actions and single hydraulic cylinder actions still have multiple control modes.

specific Embodiment 3

[0096] The main difference between it and Embodiment 1 lies in that in Embodiment 1, a synchronous speed regulating valve is set on each branch oil circuit with a rod cavity to realize the synchronous action of the two hydraulic cylinders. In this embodiment, a synchronous speed regulating valve can also be set on the branch oil circuit of the rod cavity, or a synchronous speed regulating valve can be respectively set on the branch oil circuit of the rod cavity and the branch oil circuit of the rodless cavity, so as to realize the synchronization of the two hydraulic cylinders. action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com