Contact device for cone ring transmission

A technology of compression device and transmission, applied in the direction of transmission, friction transmission, transmission control, etc., can solve problems such as interruption of torque flow and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

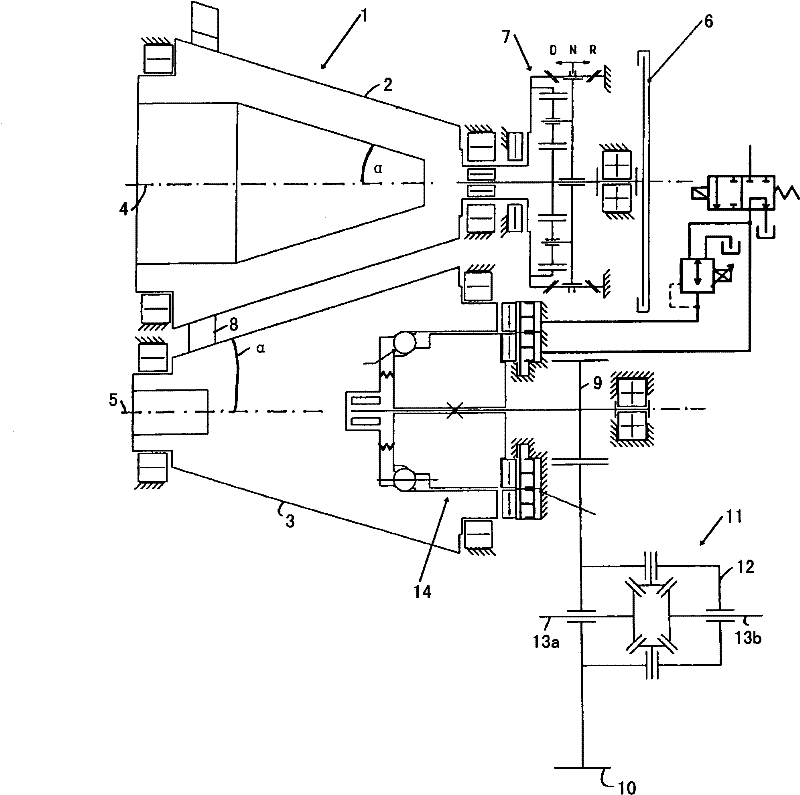

[0022] figure 1 A cone ring transmission is shown, which is generally designated 1 . The bevel ring transmission 1 has a first conical friction wheel 2 and a second conical friction wheel 3 . The conical friction wheels 2 , 3 are arranged opposite one another, with their axes of rotation extending parallel and spaced apart from one another. The axes of rotation of the conical friction wheels 2 , 3 are indicated by dashed lines 4 , 5 . Each conical friction wheel 2, 3 has an opening angle α.

[0023] In addition to the cone ring transmission 1, figure 1 Also shown is a clutch 6 of the motor vehicle which is not further shown here. A front transmission 7 is connected between the first conical friction wheel 2 and the clutch 6 . The front drive 7 in the form of a planetary gear train can switch between the two driving directions of the motor vehicle (forward, backward). In the engaged state, the clutch 6 transmits the torque of the driving device or the motor (not shown) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com