Method and device for implementing jet lubrication among rolling bearing rings

A rolling bearing and spray lubrication technology, which is applied in bearing assembly, engine lubrication, bearing components, etc., can solve problems such as difficult to control the oil injection amount of rolling bearings, and achieve the effect of weakening the influence, facilitating control, and maintaining the running state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

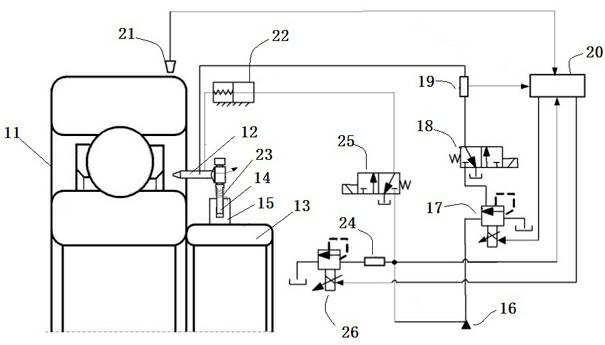

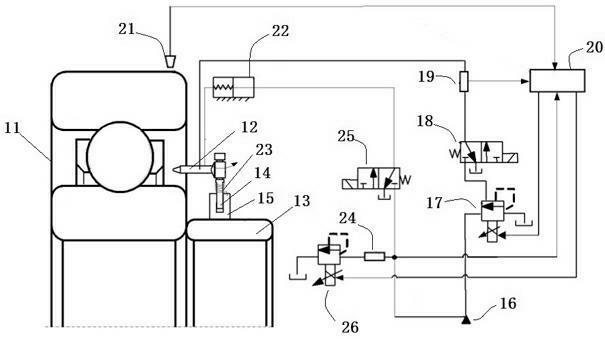

[0020] Embodiment 1 of the injection lubrication method between rolling bearing rings of the present invention, as figure 1 As shown, the following steps are included: 1) Install a rotating nozzle 12 on one axial side of the rolling bearing 11, make the rotation axis of the nozzle 12 perpendicular to the rotation axis of the rolling bearing 11 and make the nozzle of the nozzle 12 face the inner ring of the rolling bearing 11 and between the cages. In this embodiment, this step is completed in such a way that the outer ring rotates when the rolling bearing 11 works, so an accompanying ring 13 corresponding to the inner ring of the rolling bearing 11 is provided on the axial side of the inner ring of the rolling bearing 11, and the accompanying ring 13 is opposite to the inner ring of the rolling bearing 11. When the inner ring of the rolling bearing 11 is stationary, the nozzle 12 is rotated on one side of the rolling bearing 11 through a base shaft 14 provided on the accompany...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com