Gear with surface texture tooth surfaces

A technology of surface texture and gears, applied to components with teeth, belts/chains/gears, gear lubrication/cooling, etc., can solve problems affecting the working efficiency and service life of mechanical equipment, and affect the performance of mechanical systems, etc., to achieve Reduced friction coefficient, small groove width, and reduced abrasive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

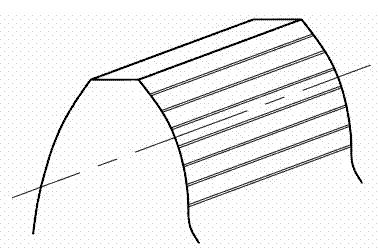

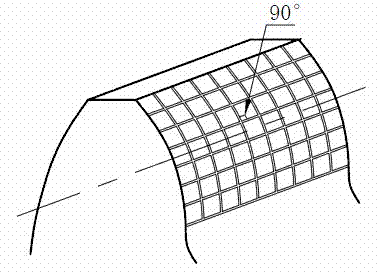

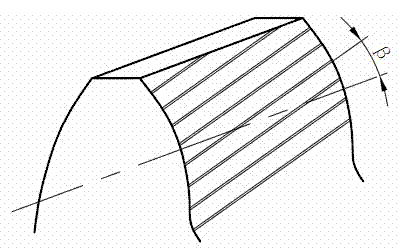

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is provided with evenly arranged surface texture marks on each tooth surface of the gear.

[0026] Such as figure 1 , image 3 As shown, the surface texture marks are strip-shaped convex marks or strip-shaped dent-shaped surface texture marks parallel to the gear meshing line. It is conducive to the formation of a dynamic pressure lubricating film, the texture direction is parallel to the gear meshing line, the groove width along the speed direction is small, the dynamic pressure effect is enhanced, and the friction coefficient is reduced, thereby reducing the friction and wear of the tooth surface.

[0027] Such as figure 2 , Figure 4 As shown, the surface texture trace type is a surface texture trace type with grid-like convex grooves or grid-like dent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com