Nickel/aluminum oxide catalyst microsphere and preparation method thereof

A catalyst and catalyst quality technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of reducing catalyst activity, influence, and improving catalyst strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

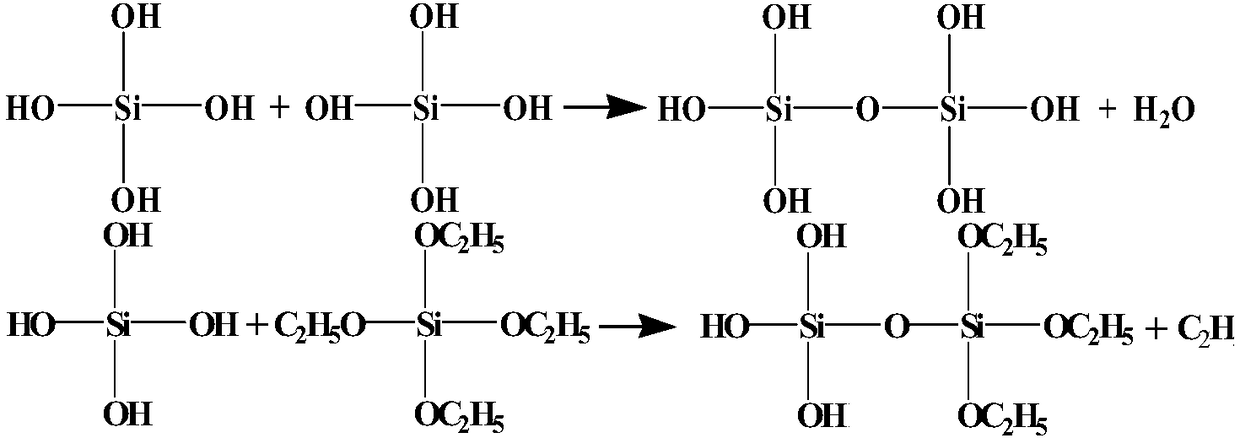

[0056] (1) 596g Ni(NO 3 ) 2 ·6H 2 O, 96.4g Mg(NO 3 ) 2 ·6H 2 O and 641g Al(NO 3 ) 3 9H 2 O was dissolved in 2000mL of deionized water, and then 53g of tetraethyl silicate was added to obtain a mixed solution. NaOH solution was added to adjust the pH of the mixed solution to 11. precipitation reaction;

[0057] (2) After the co-precipitation reaction in step (1) is completed, continue to stir for 1 hour, then transfer the precipitate to a high-pressure reactor for hydrothermal reaction, the temperature of the hydrothermal reaction is 160°C, keep the reaction for 4 hours, and obtain the catalyst after the reaction is completed Precursor slurry;

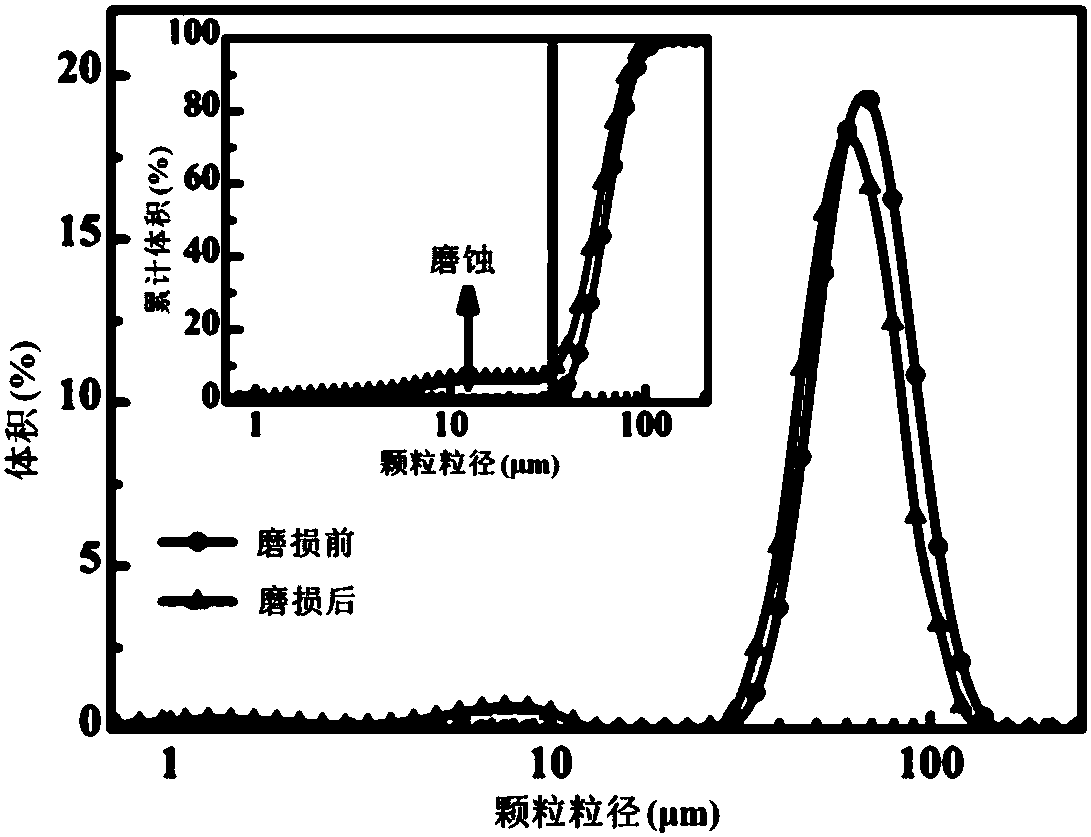

[0058] (3) Use ionized water to wash the precursor slurry obtained in step (2) to neutrality, filter and dry at 100°C for 10 h, and then use a ball mill to pulverize it into a fine powder below 3 μm, and mix the obtained fine powder with deionized water Mixing and preparing a slurry with a solid content of 60wt.% in a high-spe...

Embodiment 2

[0061] (1) 238g Ni(NO 3 ) 2 ·6H 2 O, 211g Zr(NO 3 ) 4 ·5H 2 O and 801g Al(NO 3 ) 3 9H 2 O was dissolved in 2000mL of deionized water, and then 106g of tetraethyl silicate was added to obtain a mixed solution. Aqueous ammonia solution was added to adjust the pH of the mixed solution to 10. precipitation reaction;

[0062] (2) After the co-precipitation reaction in step (1) is completed, continue to stir for 1 h, then transfer the precipitate to a high-pressure reactor for hydrothermal reaction, the hydrothermal reaction temperature is 200 ° C, keep the reaction for 10 h, and obtain the catalyst after the reaction is completed Precursor slurry;

[0063] (3) Use ionized water to wash the precursor slurry obtained in step (2) to neutrality, filter and dry at 100°C for 10 h, and then use a ball mill to pulverize it into a fine powder below 3 μm, and mix the obtained fine powder with deionized water Mixing and preparing a slurry with a solid content of 50wt.% in a high-spe...

Embodiment 3

[0068] (1) 238g Ni(NO 3 ) 2 ·6H 2 O, 8g La(NO 3 ) 3 9H 2 O and 945g Al(NO 3 ) 3 9H 2 O was dissolved in 2000mL deionized water, and then 212g tetraethyl silicate was added to obtain a mixed solution, and Na 2 CO 3 The solution adjusts the pH of the mixed solution to 10, puts the mixed solution into a continuously stirred reaction kettle, and carries out coprecipitation reaction at 60°C;

[0069] (2) After the co-precipitation reaction in step (1) is completed, continue to stir for 1 hour, then transfer the precipitate to a high-pressure reactor for hydrothermal reaction, the temperature of the hydrothermal reaction is 220°C, keep the reaction for 24 hours, and obtain the catalyst after the reaction is completed Precursor slurry;

[0070] (3) Use ionized water to wash the precursor slurry obtained in step (2) to neutrality, filter and dry at 100°C for 10 h, and then use a ball mill to pulverize it into a fine powder below 3 μm, and mix the obtained fine powder with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com