Engine oil of long-service life gasoline engine

A gasoline engine and engine oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of easy generation of carbon deposits, poor oxidation resistance, and restrictions on popularization and application, and achieve the effect of long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

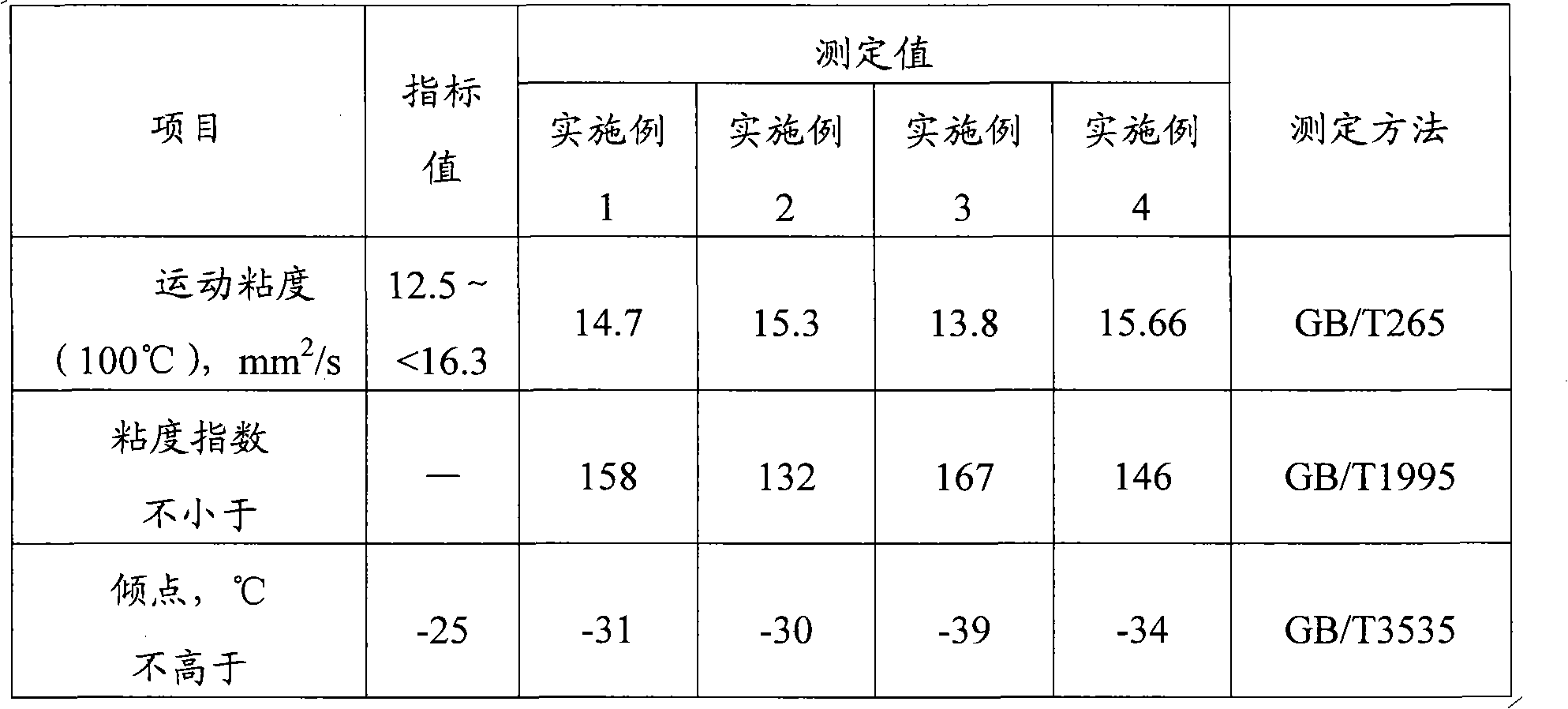

Examples

Embodiment 1

[0039] The weight percentage composition of additive is:

[0040] 3% bis-polyisobutylene succinimide, 2% monosuccinimide, 2% synthetic calcium sulfonate with a base value of 300mgKOH / g, 1% sulfurized alkyl with a base value of 200mgKOH / g Calcium phenate, 0.5% zinc dialkyldithiophosphate, 0.1% zinc dialkyldithiocarbamate, 0.1% alkylphenol, 0.08% copper nanoparticles with a particle size of 15nm to 25nm, 4.0 % of ethylene-propylene copolymer with a molecular weight of 60,000, 4.0% of a hydrogenated styrene diene copolymer with a molecular weight of 80,000, and 0.3% of polyalphaolefin;

[0041] 83% base oil, the base oil is composed of 45% API Group III base oil and 55% polyalphaolefin synthetic oil.

Embodiment 2

[0043] The weight percentage composition of additive is:

[0044] 5% bispolyisobutylene succinimide, 4.5% synthetic magnesium sulfonate with a base value of 300mgKOH / g, 0.3% zinc dialkyldithiophosphate, 0.4% dialkyldithiocarbamate Zinc, 0.2% of alkylphenol, 0.1% of nano-copper particles with a particle size of 15nm to 25nm, 9.0% of hydrogenated styrene diene copolymer with a molecular weight of 80,000, and 0.5% of polymethacrylate;

[0045] 80% base oil, the base oil is composed of 40% API Group III base oil and 60% polyalphaolefin synthetic oil.

Embodiment 3

[0047] The weight percentage composition of additive is:

[0048] 3.5% T-155 polyisobutylene succinimide, 1.5% monosuccinimide, 4% sulfurized calcium alkylphenate with a base value of 250mgKOH / g, 0.5% dialkyldithio Zinc carbamate, 0.15% alkylphenol, 0.15% nano-copper particles with a particle size of 15nm to 25nm, 3.0% ethylene-propylene copolymer with a molecular weight of 50,000, and 3.0% hydrogenated styrene diene with a molecular weight of 60,000 Copolymer, 0.4% polyalphaolefin;

[0049] 83.8% base oil, the base oil is composed of 60% API III base oil and 40% polyalphaolefin synthetic oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear stability index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com