Multifunctional wet brake for forkman driving bridge

A technology of wet brakes and drive axles, which is applied in the direction of brake types, brake components, brake actuators, etc., which can solve the problems of large size and easy interference with other parts, and achieve the effects of weight reduction, labor-saving operation, and easy and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

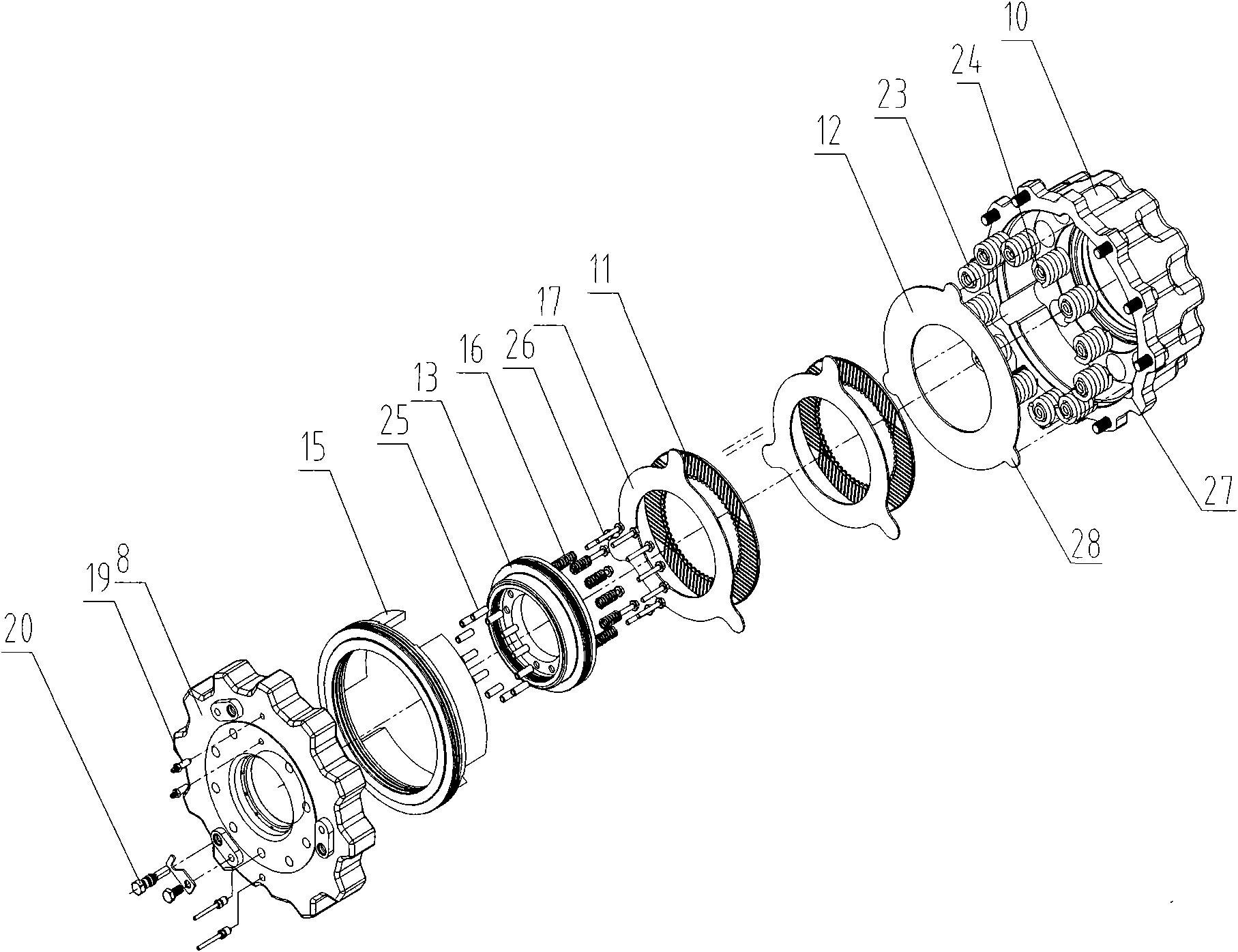

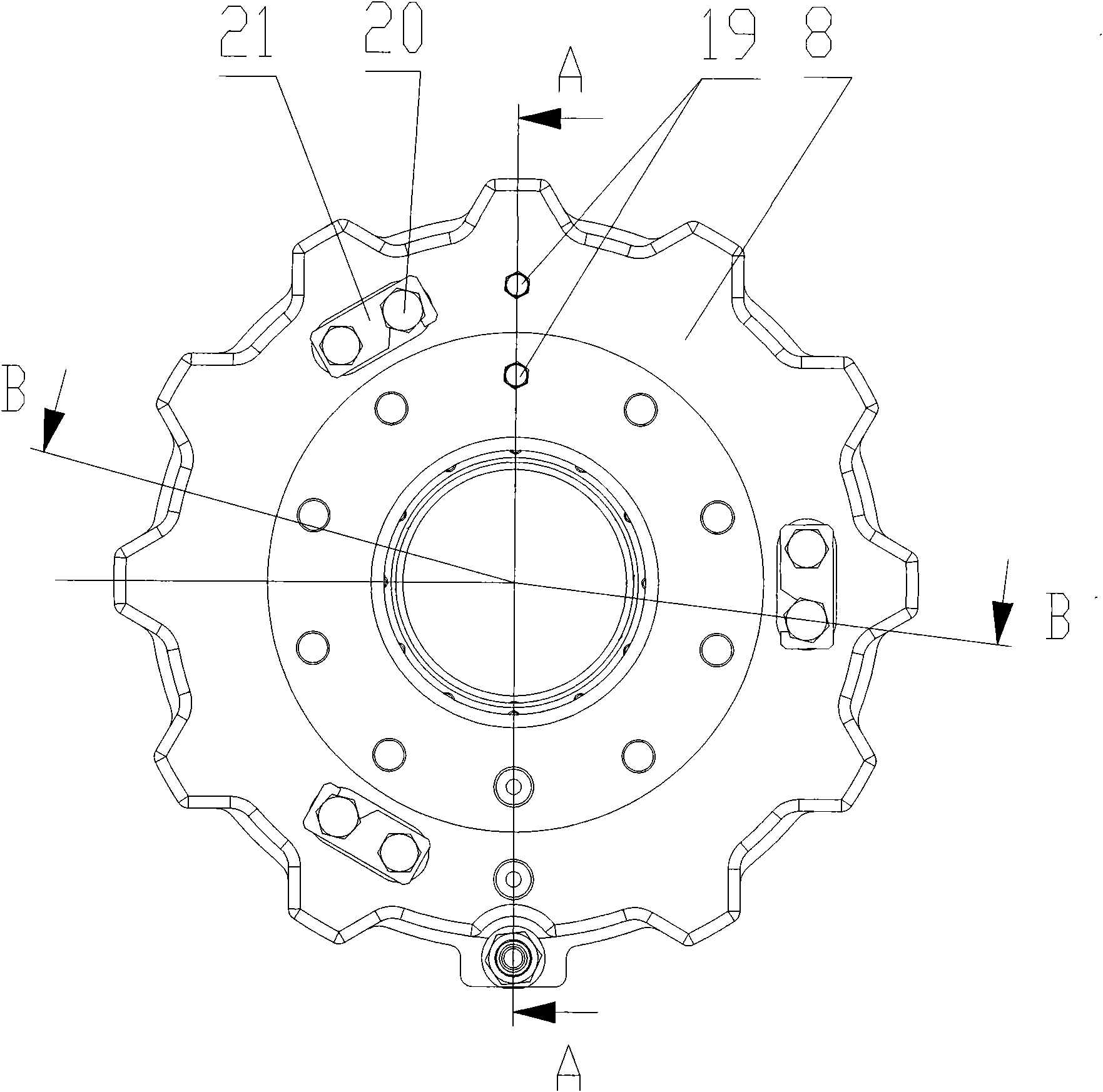

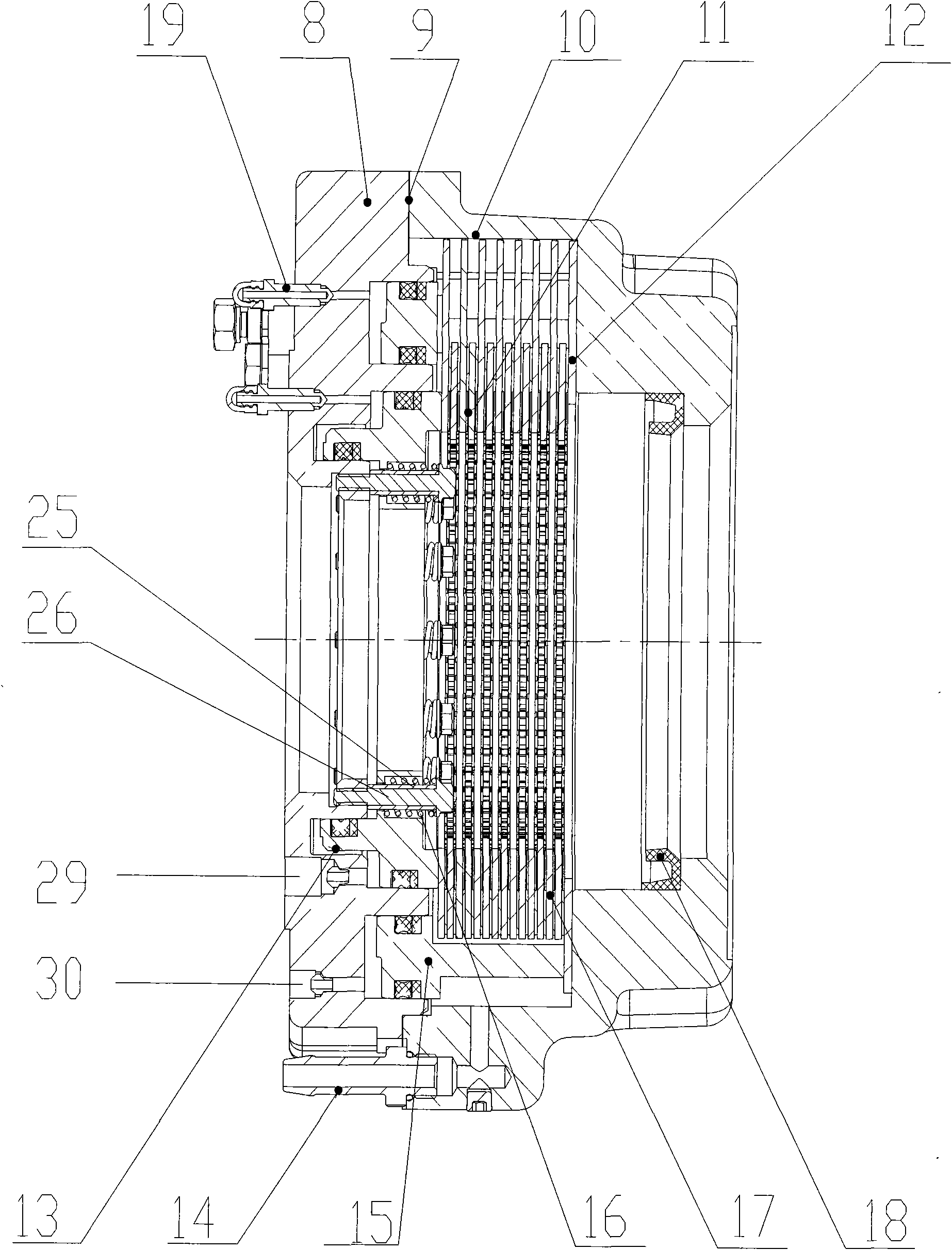

[0025] see figure 1 , figure 2 , the multifunctional wet brake for forklift driving axle includes left housing 8, right housing 10, service brake piston 13, parking brake piston 15, friction plate 11, spacer 17, parking spacer 12, gasket 9, card Ring 21, O-ring 22 and oil seal 18;

[0026] An isolation ring is provided inside the left housing 8, and the service brake piston 13 is located inside the isolation ring. Twelve bolt holes are evenly arranged on the corresponding end faces of the service brake piston 13 and the friction plate 11, and a limit sleeve 25 is arranged in the bolt holes. , the bolt 26 covered with the return spring 16 is fixedly connected to the left housing 8 through the limit sleeve 25, and the head of the bolt passes through the center hole of the spacer;

[0027] The parking brake piston 15 is sleeved on the outside of the spacer ring, and twelve spring holes are evenly distributed in the right housing 10 corresponding to the parking brake piston 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com