Hydraulic double-cylinder braking caliper assembly

A brake caliper, hydraulic technology, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems of increased friction plate wear, unusable brake, abnormal brake noise, etc., to improve braking force, Excellent NVH performance to ensure braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

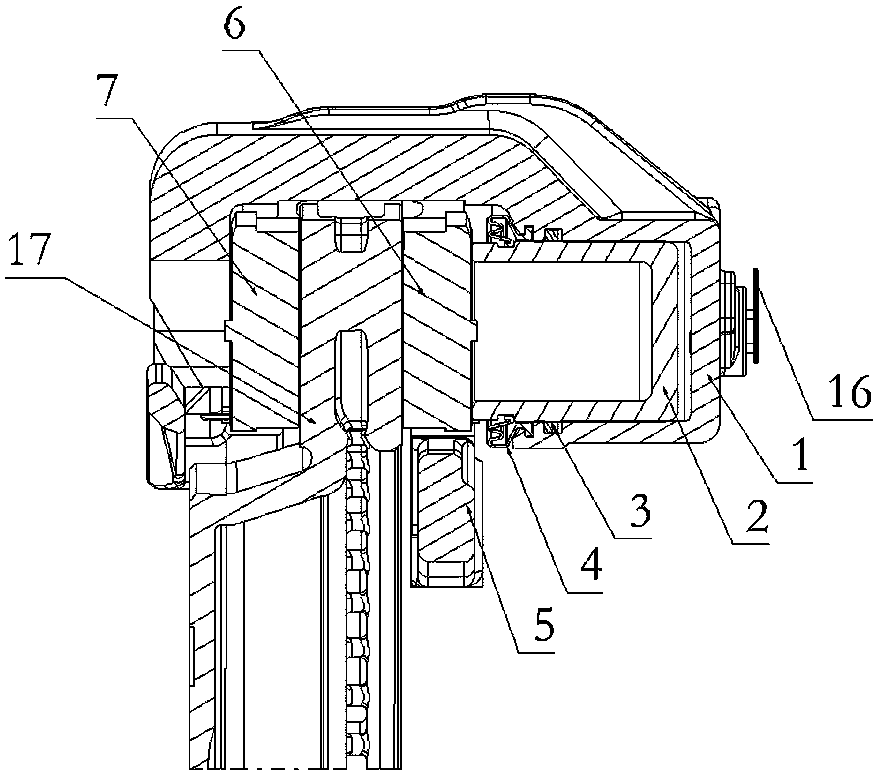

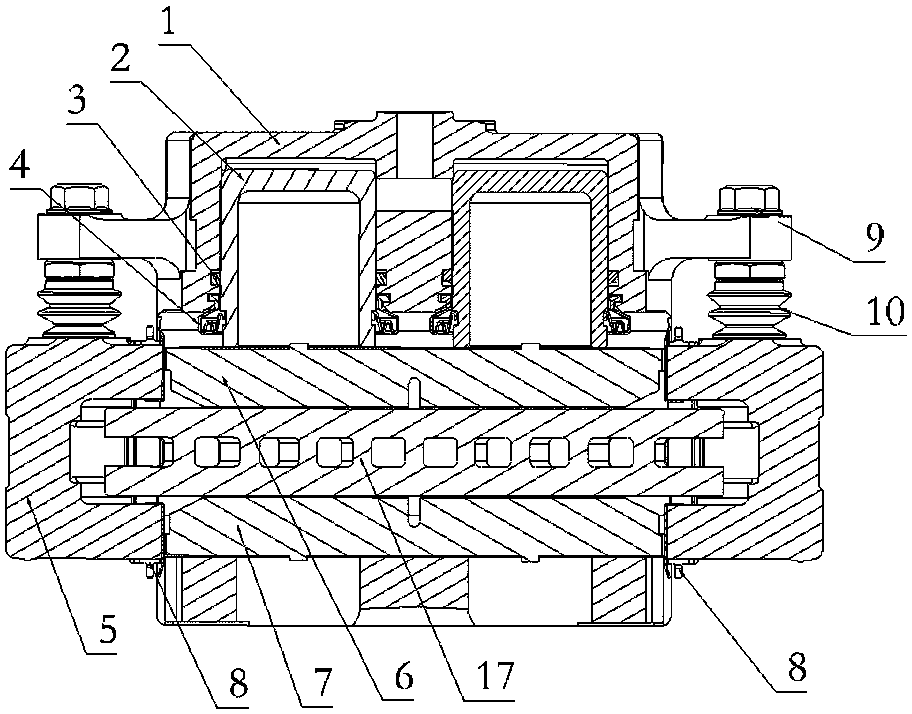

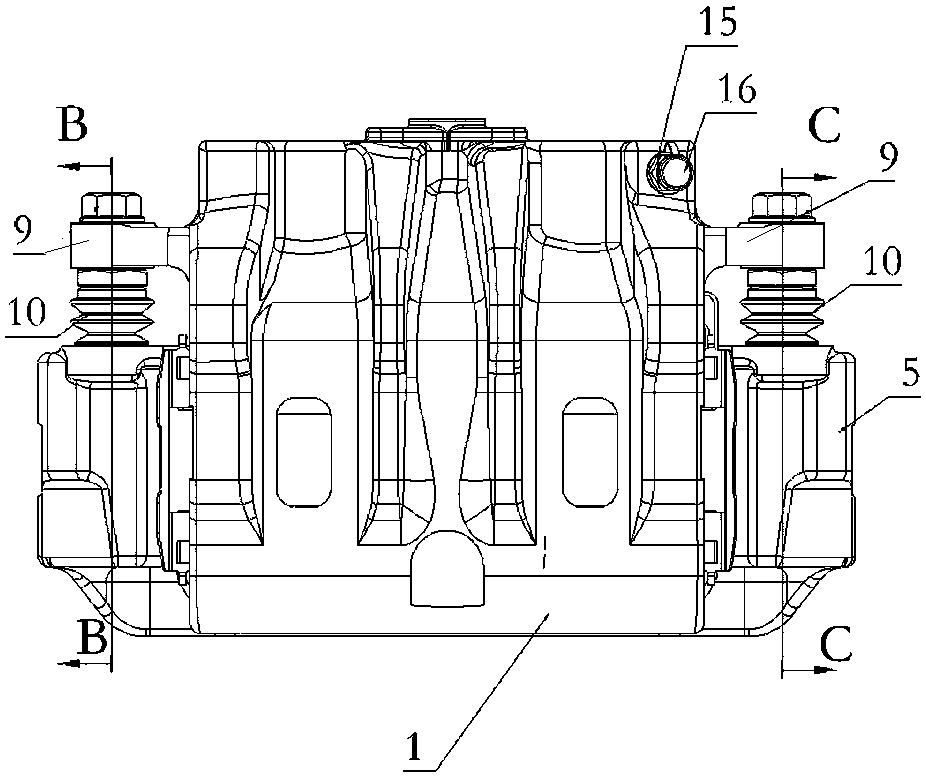

[0059] Such as figure 1 -6 shows a hydraulic double-cylinder brake caliper assembly of the present invention, which is characterized in that it includes a caliper body 1 with two hydraulic chambers, the two hydraulic chambers are connected at the bottom, and pistons 2 are respectively arranged inside;

[0060] It also includes a fixed frame 5, on which an inner friction plate 6 and an outer friction plate 7 are connected through a yoke spring 8, the friction surfaces of the two friction plates are opposite and both are in clearance fit with the brake disc 17;

[0061] Pin holes are provided on both sides of the fixed frame, and the pin shaft 11 slidingly fitted with the pin hole 12 is connected with the lifting lug 9 on the outside of the caliper body through bolts;

[0062] Be provided with the bushing 13 that cooperates with pin shaft in the pin hole, be provided with air release screw 14 on the caliper body, be provided with air release cap 15 on the air release screw.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com