Method for installing and dismantling device for connecting main shaft of large-scale mine elevator with motor rotor

A technology of mine hoist and motor rotor, which is applied to lifting equipment, transportation and packaging in mines, can solve problems such as difficulty and inability to guarantee, and achieve the effect of simple and easy operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

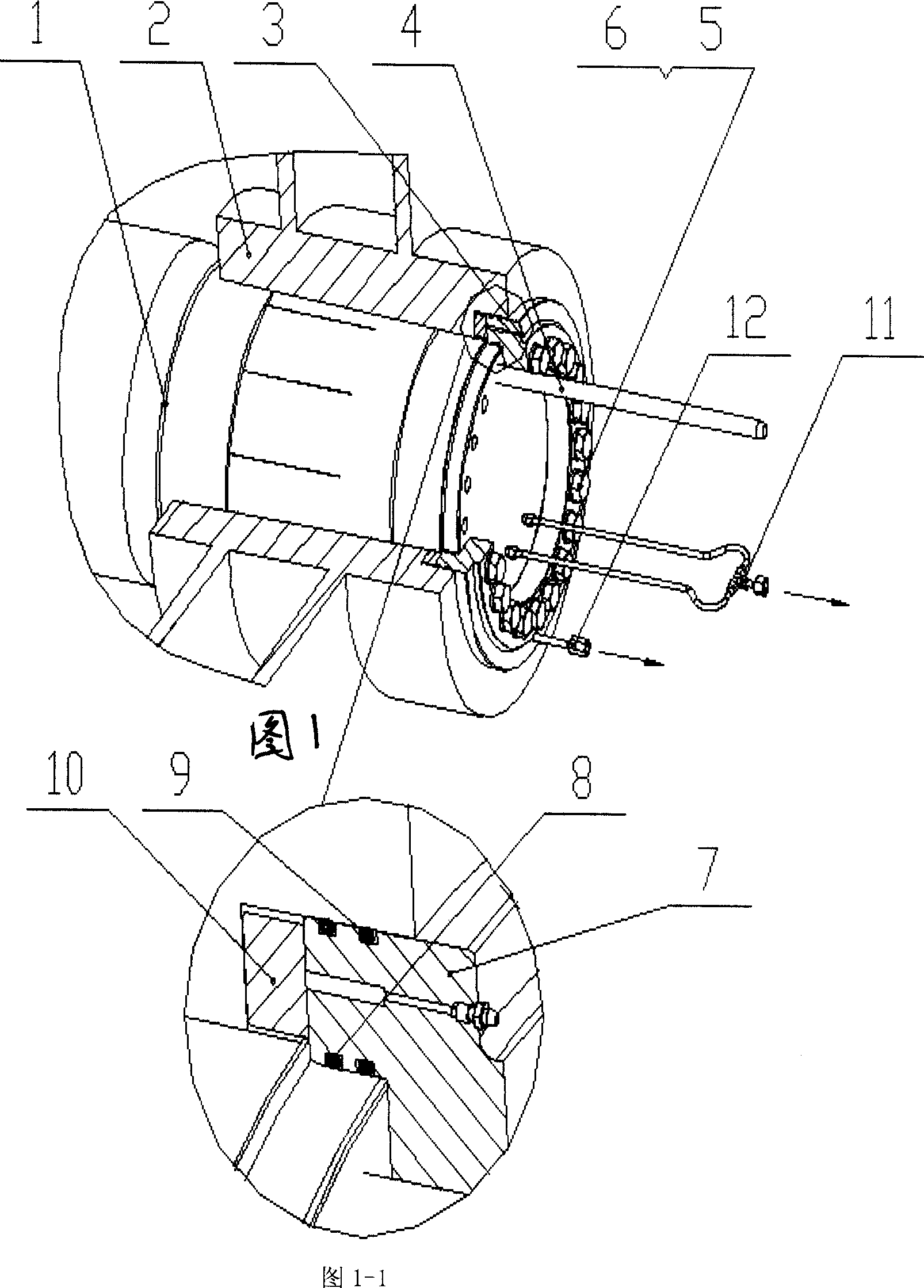

Embodiment 1

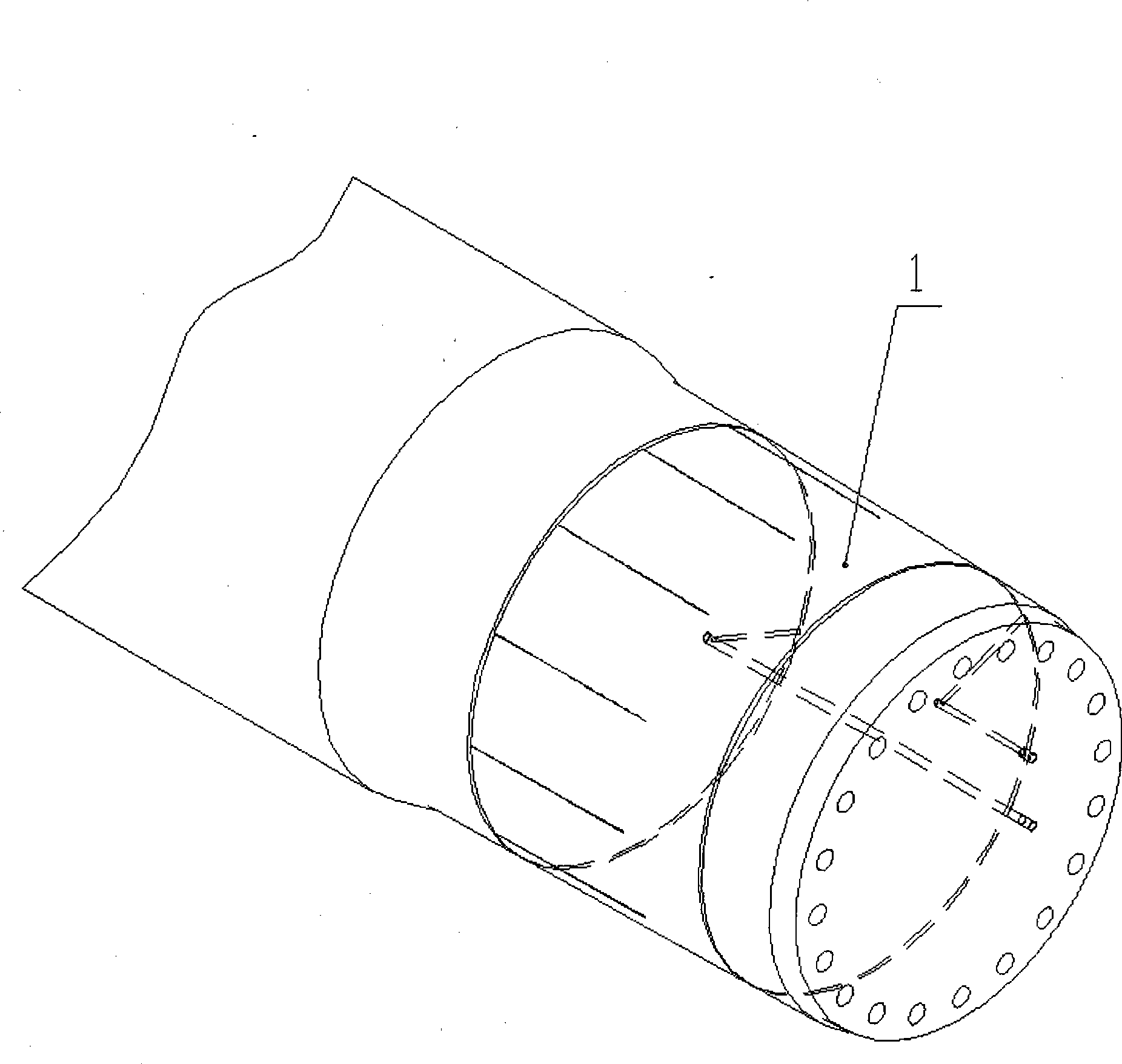

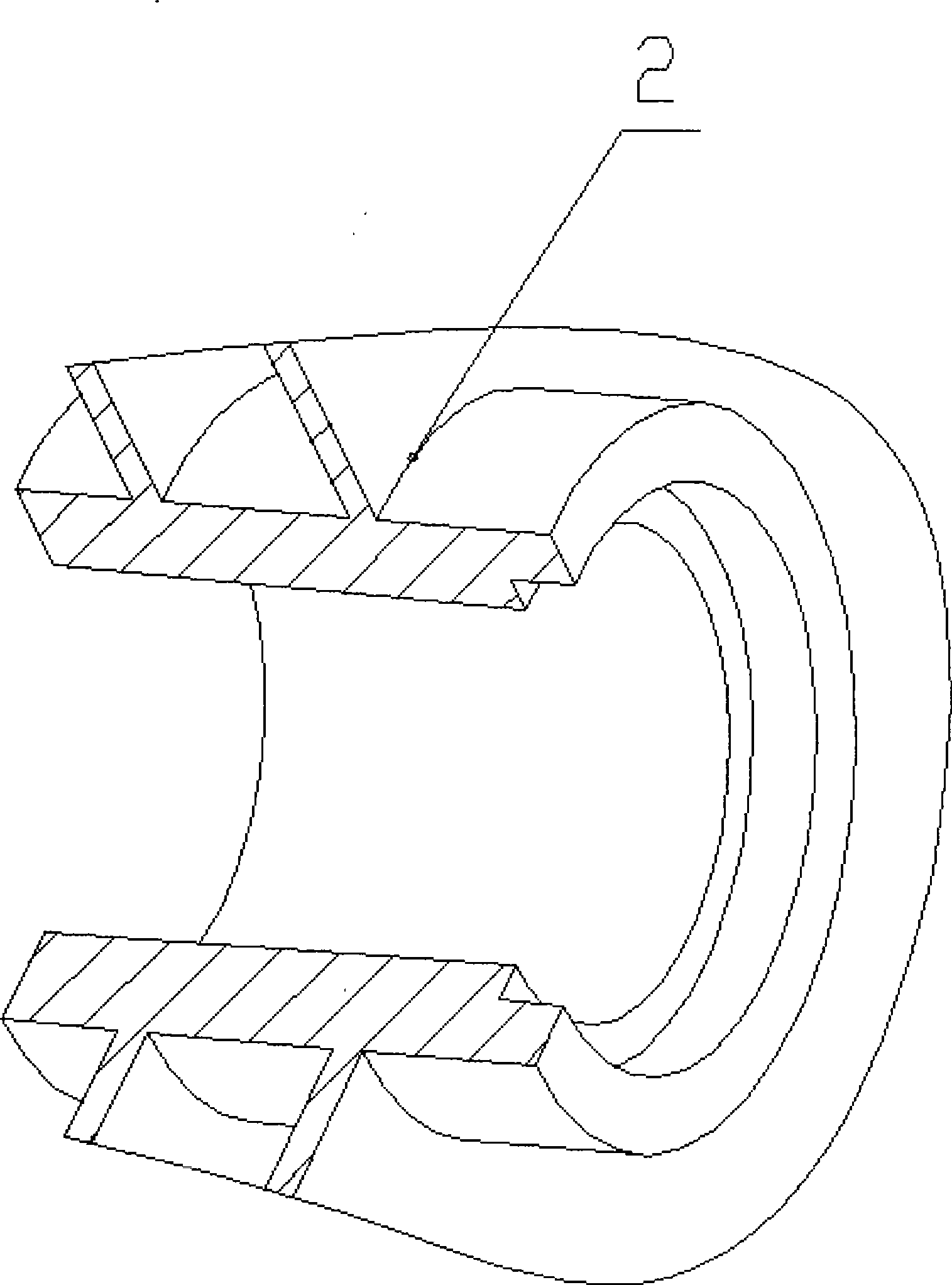

[0047] a. Clean the tapered hole of the motor rotor hub (2) and the tapered surface of the hoist main shaft (1), and there must be no oil, any other impurity particles and metal burrs.

[0048] b. Lift the motor rotor (2) with a crane, and place it on the shaft end of the main shaft (1).

[0049] c. Put sealing ring 1 (8) and sealing ring 2 (9) on the hydraulic cover (7).

[0050] d. Screw the bleed screw (3) into the bleed hole on the hydraulic cover.

[0051] e. Use the installation rod (4) to install the hydraulic cover to the shaft end. It should be noted that the air release screw (3) must be placed at the upper position.

[0052] f. Install the bolts (5) and washers (6), and tighten the bolts.

[0053] g. Connect the oil pump, if attached Figure 5 shown.

[0054] Use the adapter 1 (11) to connect the oil hole on the shaft head with the oil pump 1 (13), so that the pressure oil goes along the axial oil path of the main shaft, and then reaches the mating surface of the...

Embodiment 2

[0056] h. Prepare to charge oil to the two oil pumps.

[0057] Oil pump 2 (14) gives the rotor axial thrust, and oil pump 1 (13) gives the rotor radial expansion force and forms an oil film between the contact surface of the rotor and the main shaft.

[0058] i. Make the hoisting rope for hoisting the rotor stressed, and the horizontal force makes the rotor as close as possible to the main shaft, and then use the oil pump 2 (14) to fill the cavity formed by the motor rotor and the hydraulic cover on the main shaft, and the air is fed by the air release screw (3) discharge.

Embodiment 3

[0060] Air release method: use oil pump 2 (14) to charge oil, the amount of oil is to fill the cavity formed by the motor rotor and hydraulic cover until oil overflows from the air release screw, loosen the air release screw, and the mixture of air and oil overflows , until there are no bubbles in the overflow, and it is all oil, tighten the air release screw.

[0061] j. Use the oil pump 2 (14) to give the oil pressure 0.5-3MPa, so that the rotor hub is in close contact with the main shaft, then mark the initial position of the rotor in the axial direction, and mark the end position that needs to be advanced according to the given advancing distance , while measuring the axial propulsion distance of the rotor with a dial gauge or a depth gauge. The axial propulsion distance of the rotor is determined by the taper of the main shaft cone and the interference. For example, if the taper is 1:30 and the calculated interference is 0.6mm, the propulsion distance is 30×0.6mm=18mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com