Gear selecting and shifting hydraulic soft shaft

A shift selection, hydraulic technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem that the shift selection flexible shaft cannot transmit the driver's operation intention 100%, affecting the shifting accuracy. , comfort, affecting the shifting feel and other issues, to achieve the effect of improving the shifting feel, improving the shifting comfort, and having a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

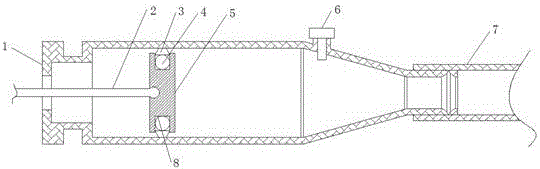

[0016] refer to Figure 1-2 , a hydraulic flexible shaft for shifting gears, including a hydraulic cylinder housing 1, a push rod 2 is provided on one side of the hydraulic cylinder housing 1, and one end of the push rod 2 extends into the hydraulic cylinder housing 1, and a piston is arranged in the hydraulic cylinder housing 1 5. The piston 5 is connected with the push rod 2. There is a groove 8 in the middle of the piston 5. A first seal ring 4 is arranged between the inner walls of the groove 8. The side of the first seal ring 4 away from the piston 5 is provided with a second seal. The other side of the ring 3 and the hydraulic cylinder housing 1 is connected with a shaft body 7 , and the side of the hydraulic cylinder housing 1 close to the shaft body 7 is provided with an air release screw 6 . The beneficial effects of the present invention are: reasonable design, easy to use, the gas in the hydraulic pipeline can be drawn out through the vent screw hole by using the ve...

example 1

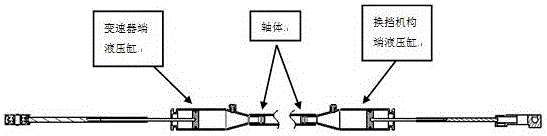

[0018] Example 1: There are two hydraulic cylinder housings 1, one is the hydraulic cylinder at the transmission end, and the other is the hydraulic cylinder at the shift mechanism end. A shaft body 7 is connected between the hydraulic cylinder at the transmission end and the hydraulic cylinder at the shift mechanism end. and the shift mechanism end joints are traditional automobile gear selection flexible shafts, wherein the transmission end joint and the shift mechanism end joint are connected with the transmission end hydraulic cylinder and the shift mechanism end hydraulic cylinder through the push rod 2 respectively. The air screw 6 can extract the gas in the hydraulic pipeline through the exhaust screw hole, and prevent the liquid from overflowing through the screw seal, and has the function of supplementing the liquid; the first seal ring 4 and the second seal ring 3 cooperate to have It has the characteristics of low starting resistance, good sealing effect, small slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com