Exhaust valve assembly of hydraulic transmission pipeline of clutch

A technology of hydraulic transmission and exhaust valve, used in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problems of slow oil filling, air residue, poor clutch separation, etc., to improve accuracy The effect of degree and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Selected embodiments of the present invention are now explained with reference to the accompanying drawings. The following descriptions of the embodiments of the present invention disclosed by those skilled in the art are only exemplary and not intended to limit the solutions of the present invention.

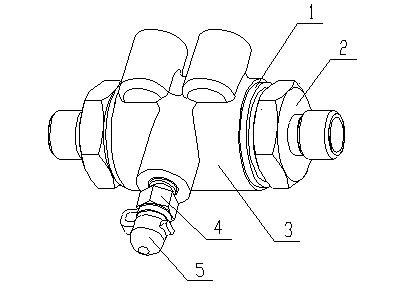

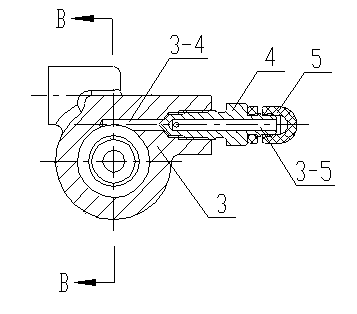

[0020] Reference attached figure 1 , a clutch hydraulic transmission pipeline exhaust valve assembly, including a valve body 3, two joint bodies 2, two sealing washers 1, air release screw 4 and dust cap 5.

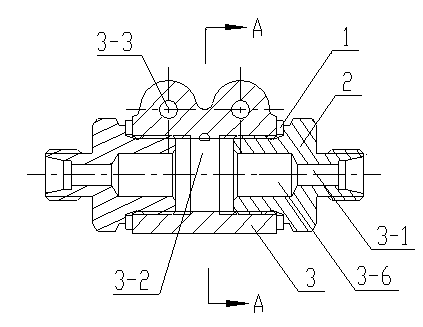

[0021] Reference attached figure 2 , The valve body 3 is a cylindrical body with a through hole inside to form a hollow structure, and an internal thread is provided near the outside of the through hole. The joint body 2 is used to connect the hydraulic oil circuit; there is a stepped through hole in the center of the joint body 2, the stepped through hole includes the inner hole 3-6 and the oil hole 3-1, and the diameter of the inner hole 3-6 is larger than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com