Brake wheel cylinder assembly for preventing collision between pistons

A technology of brake wheel cylinder and assembly, applied in the direction of brake actuator, etc., can solve the problems of piston collision, affecting service life, damage, etc., and achieve the effect of good sealing performance, prolonging service life and preventing collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

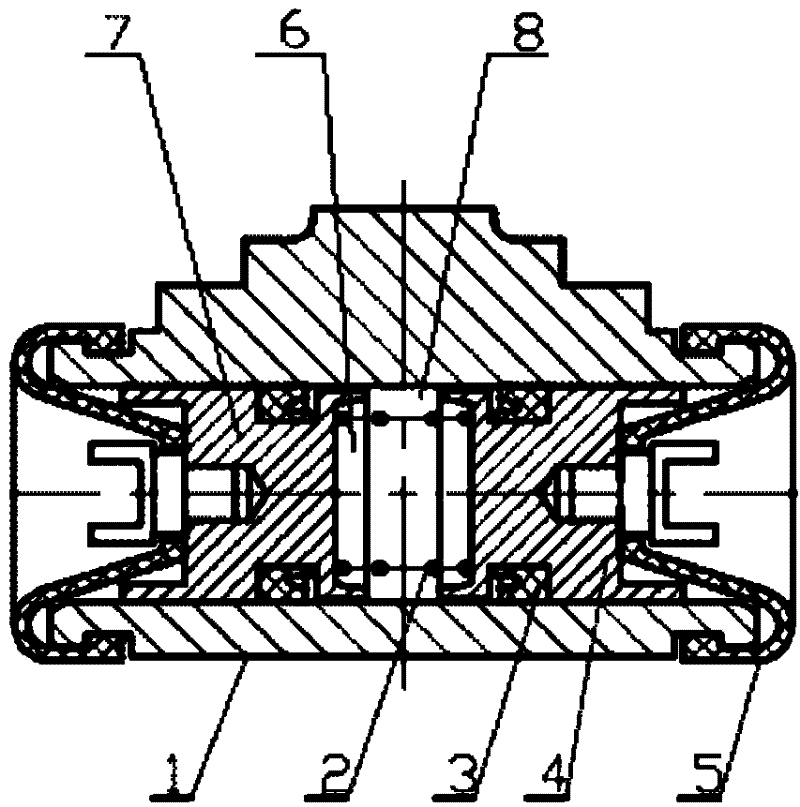

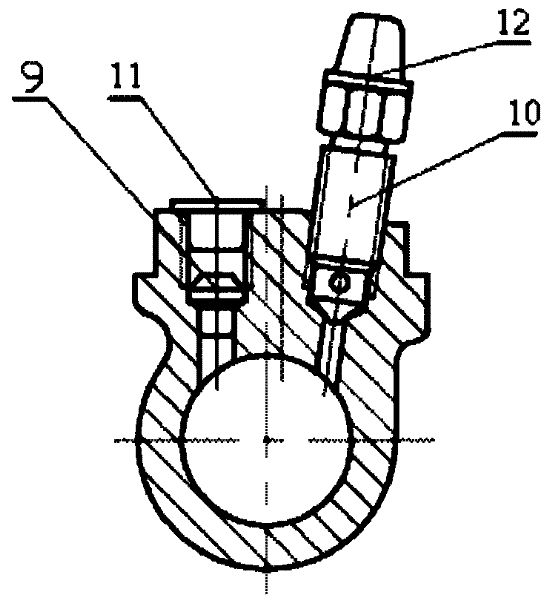

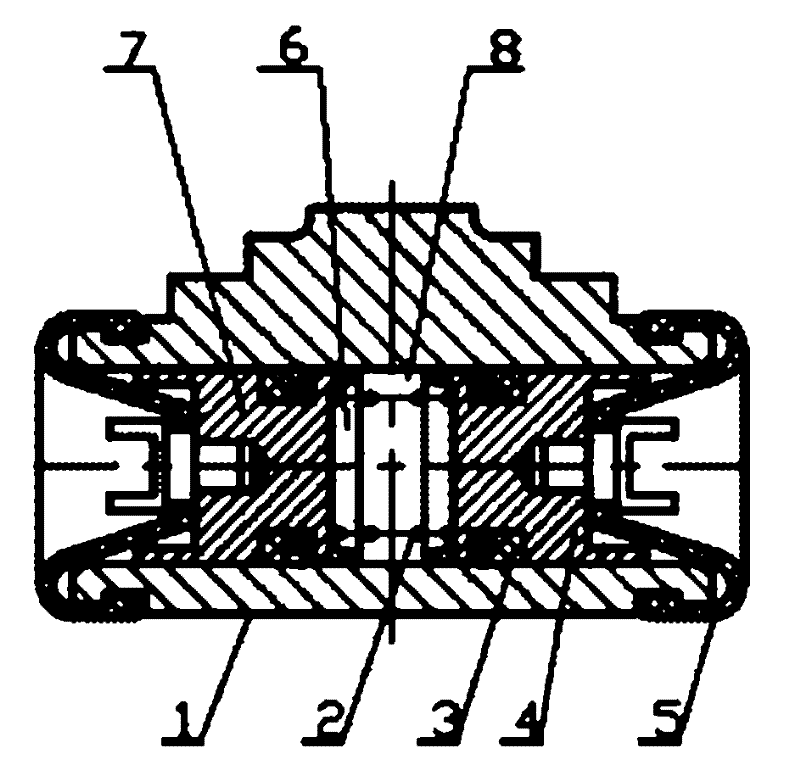

[0013] see figure 1 , 2 , A brake wheel cylinder assembly for preventing piston collision, comprising a cylinder block 1, a radial through hole 6 is arranged in the cylinder body 1, and left and right pistons 7 and 4 are arranged in the radial through hole 6. The right pistons 7 and 4 are slidably matched with the hole wall of the radial through hole 6, and a spring 2 is connected between the left and right pistons 7 and 4. The inner sides of the left and right pistons 7 and 4 are respectively provided with a bowl-shaped cavity 8. , the mouths of the bowl-shaped cavity 8 face each other; the cylinder body 1 is provided with a gas nozzle or oil nozzle 9 and a dust plug 11, and the cylinder body 1 is provided with an opening and screwed with a vent screw 10, and the vent screw The end of 10 has a vent cap 12 .

[0014] Dust covers 5 are respectively installed on the cylinders located on both sides of the radial through hole 6 ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com