Push type self-aligning hydraulic release bearing wheel cylinder unit

A release bearing and self-aligning technology, which is applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of increased separation stroke and incomplete separation, and achieve small torque loss, simple and reliable installation, and save gearbox effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

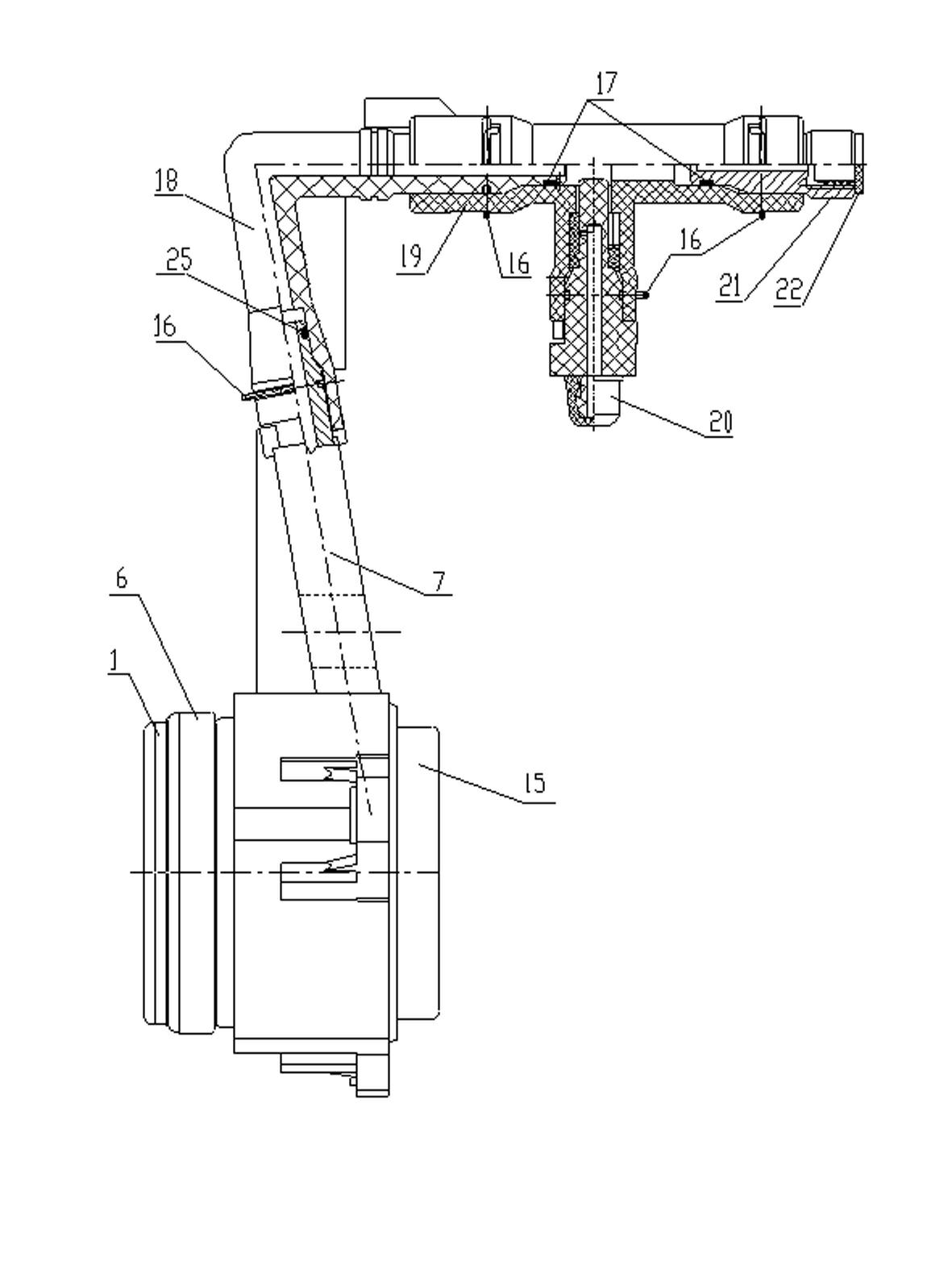

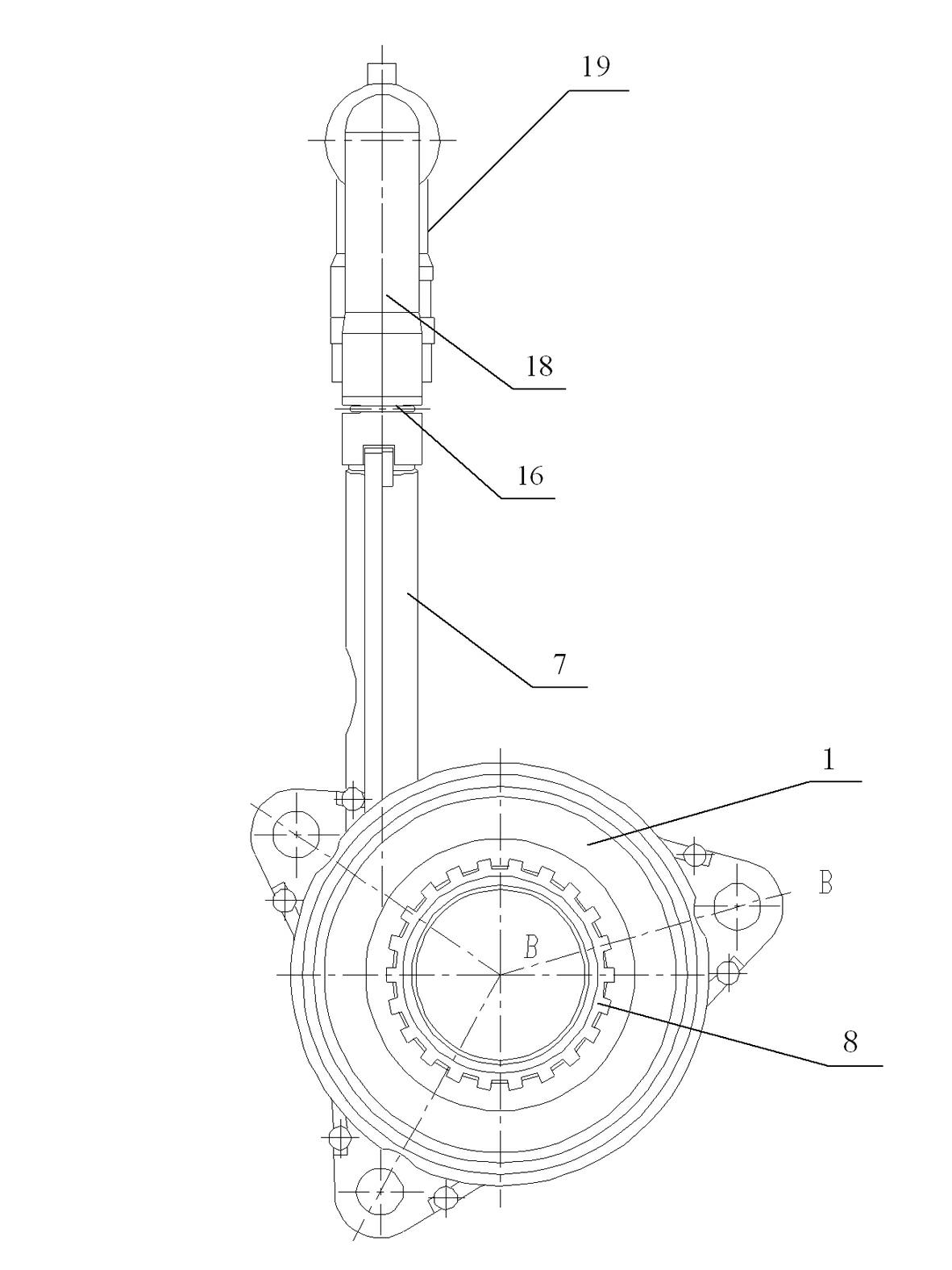

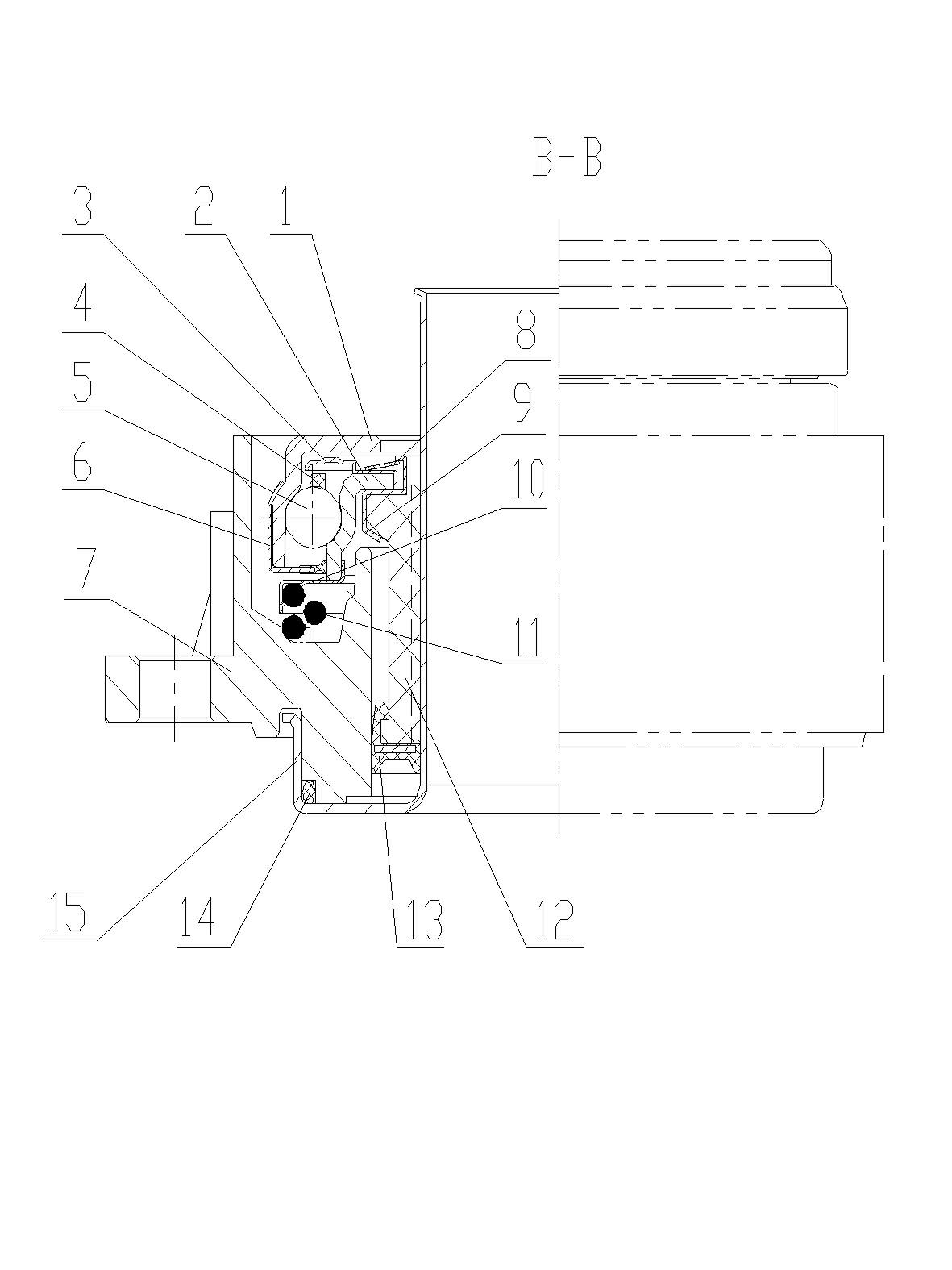

[0022] Refer to attached Figure 1~3 The push-type self-aligning hydraulic release bearing sub-pump unit includes self-aligning bearing mechanism, hydraulic sub-pump mechanism and air release device; the self-aligning bearing mechanism consists of outer ring 1, inner ring 2, cage 4, steel ball 5, The inner dust cover 3, the outer cover 6, the self-aligning spring piece 8, the sleeve 12 and the sleeve seat 9 are composed. The bearing of the self-aligning bearing mechanism adopts an angular contact design, and the centering function is realized by the self-aligning spring piece 8. The centering force That is, the force required for the radial displacement of the self-aligning spring sheet 8 after being compressed is determined by the positive pressure generated by the compressed self-aligning spring sheet 8 .

[0023] The hydraulic sub-pump mechanism is composed of a cylinder block 7, a mandrel 15, an apron 13, a mandrel sealing ring 14, a return spring 11 and a spring seat 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com