Bidirectional brake wheel cylinder assembly

A brake wheel cylinder and assembly technology, applied in the direction of brake actuators, etc., can solve the problems of restricting the action space of brake parts, poor sealing performance of pistons, and large space occupation, etc., to achieve expanded action space and good practical value , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

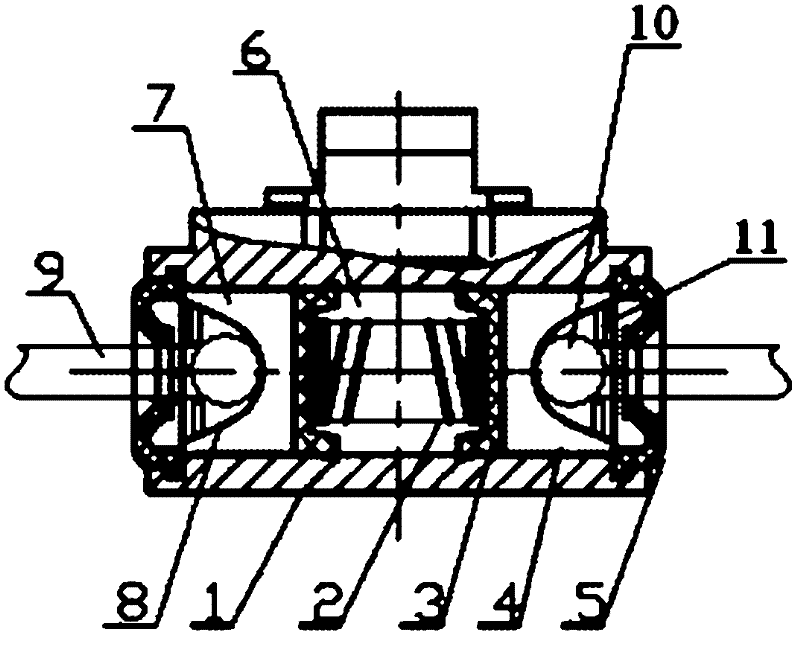

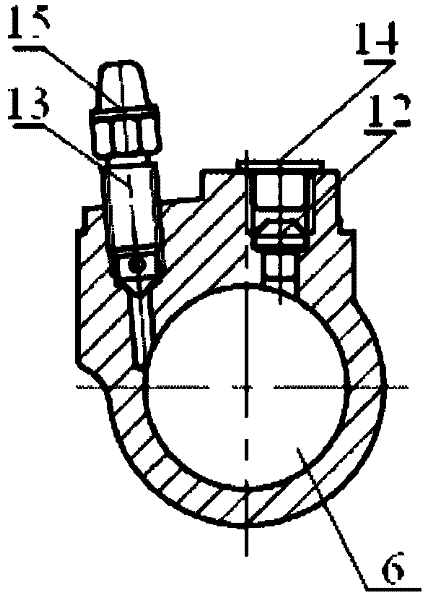

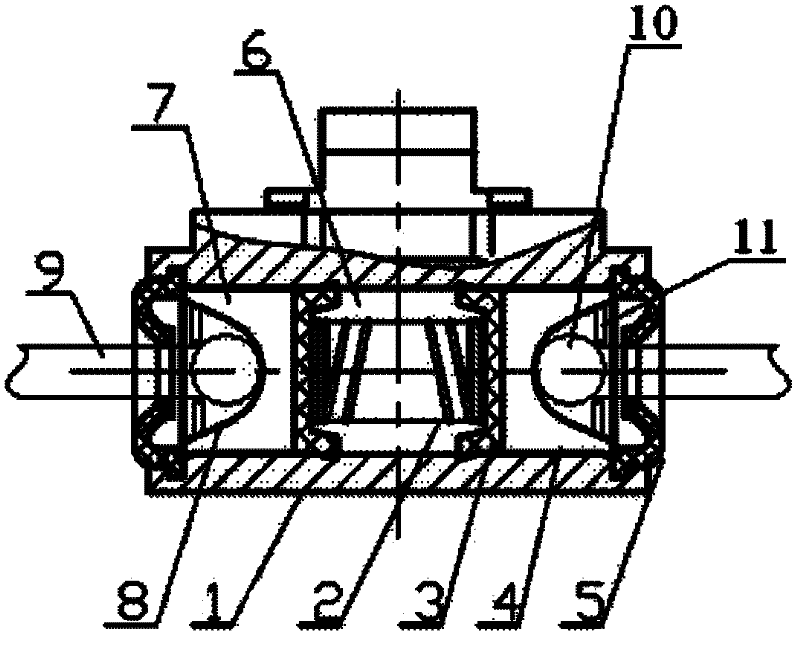

[0012] see figure 1 , 2 , a two-way brake wheel cylinder assembly, including a cylinder 1, the cylinder 1 is provided with a radial through hole 6, the radial through hole 6 is provided with left and right pistons 7, 4, left and right movable 7 , 4 plugs are slidingly matched with the hole wall of the radial through hole 6, a spring 2 is connected between the inner surfaces of the left and right pistons 7, 4, and the outer sides of the left and right pistons 7, 4 are respectively provided with a cavity 8, which is located in the diameter A dust cover 5 is respectively installed on the cylinder block 1 at both ends of the through hole 6, and the middle part of the dust cover 5 is provided with a through hole; including a push rod 9, the end of the push rod 9 has a spherical head 10, and the spherical head 10 is connected with the cavity The inner wall of 8 rotates and fits and is limited by retaining ring 11. The front end of push rod 9 passes through the through hole in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com