Integrated floating calipers

A floating caliper, integrated technology, applied in the field of calipers, can solve the problems of reducing the versatility of calipers, increasing the difficulty of distinguishing, etc., to achieve the effects of improving energy utilization efficiency, reducing machining processes, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

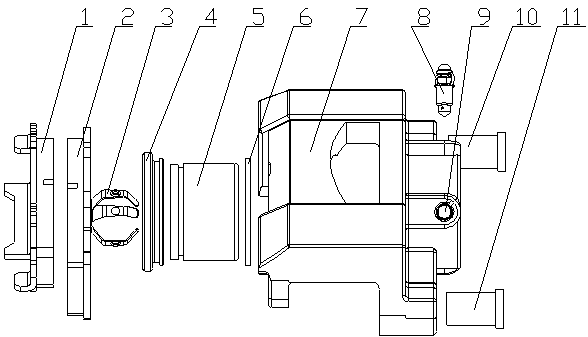

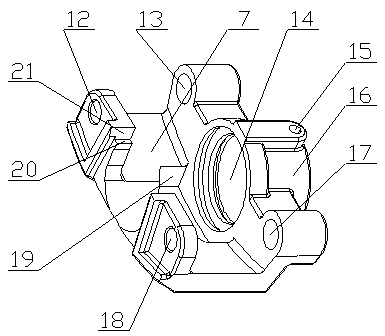

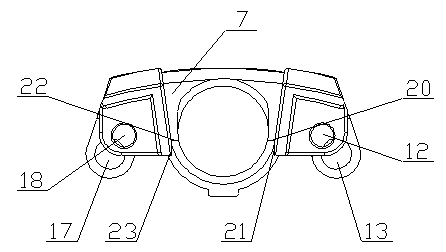

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the present invention includes an outer friction block 1, an inner friction block 2 and a pliers body 7; wherein:

[0026] 1) Pliers body 7: It is a hollow shell with a bump 16 at the center of one side in the width direction of the shell. The center of the bump 16 is opened with a piston cylinder hole 14 that is closed to the inside. The piston cylinder hole 14 is equipped with a piston 5. There are vent screw holes 25, 26 arranged symmetrically with the piston cylinder hole on both sides above the bump 16, and vent screws 8, 9 are respectively housed in the two vent screw holes 25, 26, and the bottom of the bump 16 has an inlet. The oil hole 15, the casing on the same side as the bump 16 is provided with a caliper guide hole 13 and a caliper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com