Lubricating and cooling system for vibrating roller

A vibratory roller, lubricating and cooling technology, applied in the direction of engine lubrication, engine components, lubricating parts, etc., can solve the problems of increased loss, large heat generation, bearing bearing damage, etc., to reduce heat and energy loss, and reduce deformation degree, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

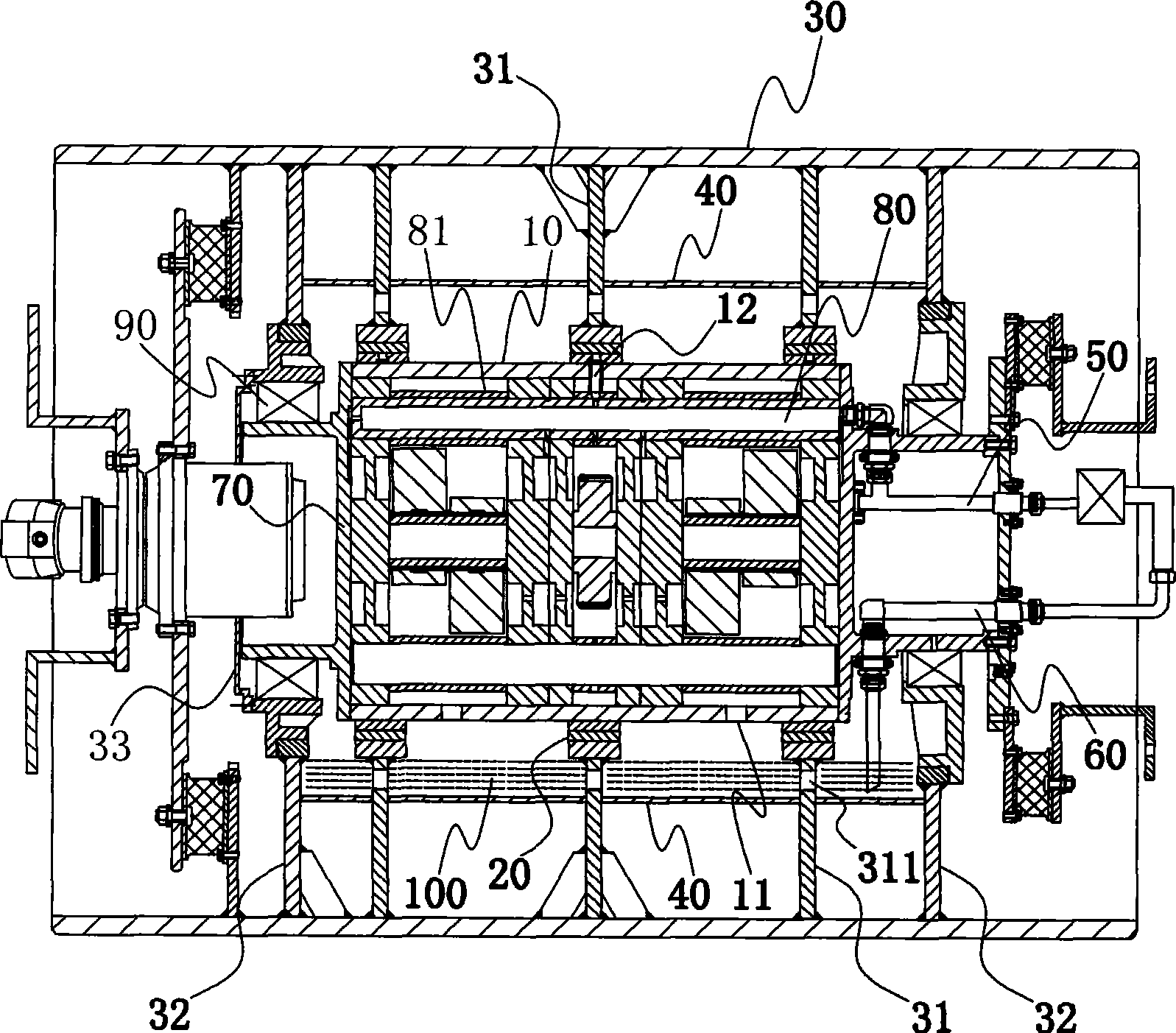

[0009] Such as figure 1 As shown, a lubricating and cooling system for a vibratory roller includes an oil pump assembly fixed on the body of the roller. The vibration exciter shell 10 and the roller body 30 are formed by bearings for rolling fit. The inside of the exciter is fixed with a vibration The fixed shaft 80 positioned by each bearing seat of the wheel assembly, the pressure lubricating oil is transported to the oil chamber inside the fixed shaft 80 through the oil supply pipe 50 of the oil pump assembly, and enters the lubricating oil of each bearing through the opening on the wall of the fixed shaft 80 Road, and then flow through each lubricating oil channel to the opening 11 on the bottom of the exciter housing 10, and converge to the bottom end surface of the roller body 30 to form an oil pool 100, the lubricating oil in the oil pool 100 passes through the oil suction pipe 60 is drawn back to the oil pump to form a complete circulating lubrication path.

[0010] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com