Online cold-pressing assembling device for oil suction pipes of compressors

An assembly device and oil suction pipe technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that there is no automatic press-fitting equipment, so as to improve assembly quality and production efficiency, improve assembly accuracy, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

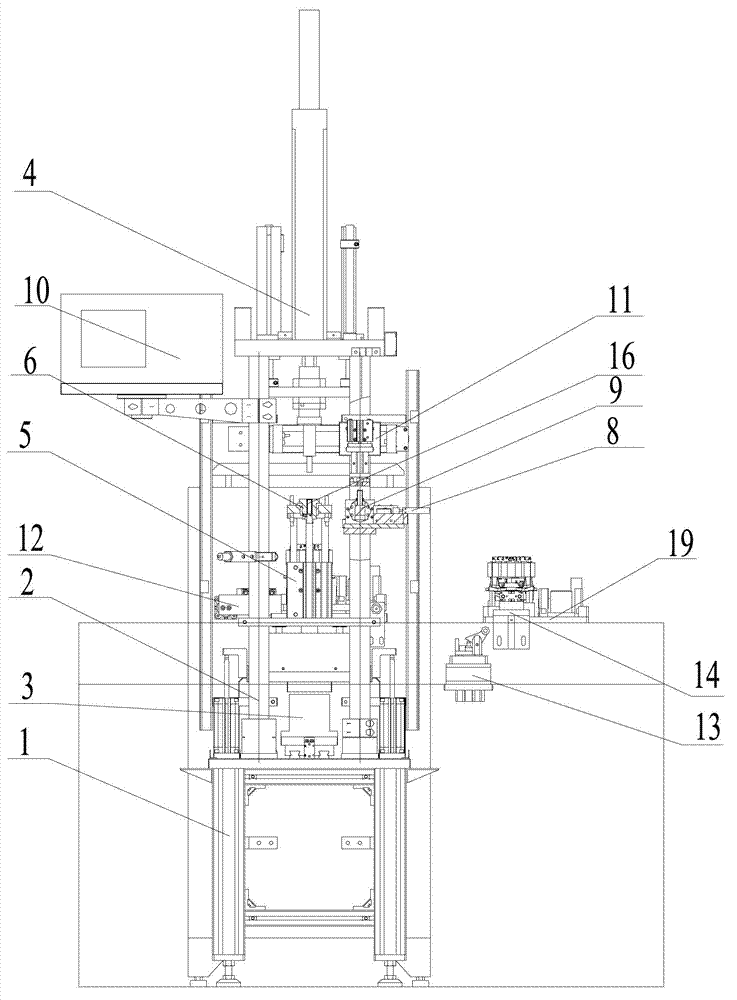

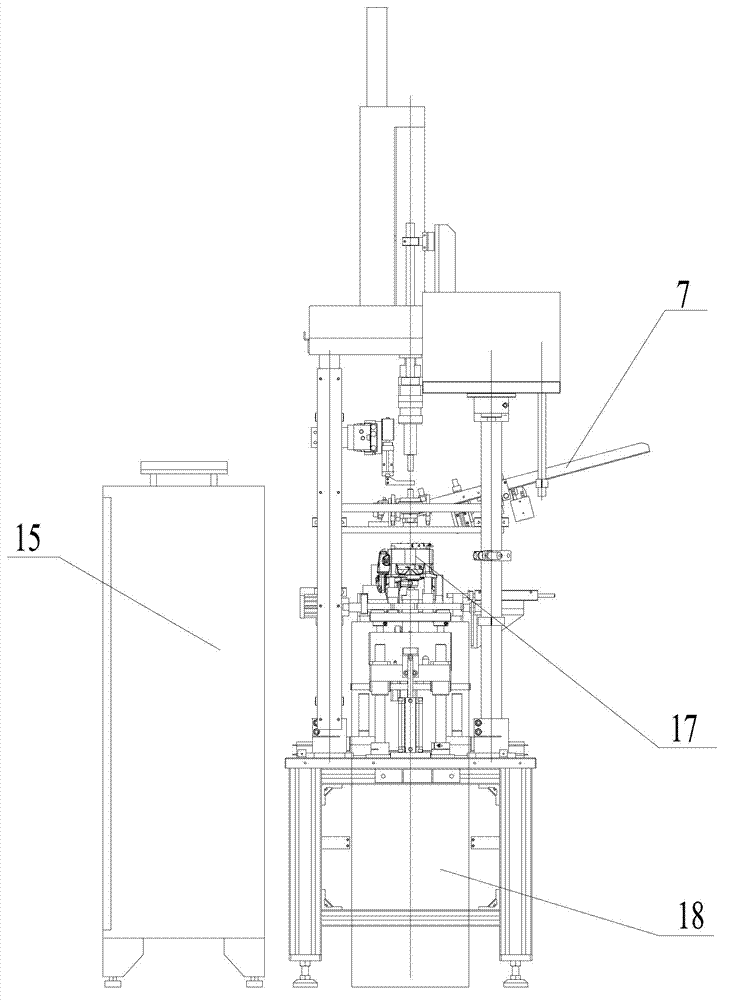

[0015] like Figure 1-2 As shown, a compressor online oil suction pipe cold press assembly device described in the embodiment of the present invention includes a frame 1 and a line body 18 matched with the frame 1, and a crankshaft positioning blocking mechanism 13 is installed on the line body 18 and the crankshaft positioning mechanism 14, the crankshaft positioning mechanism 14 is placed with a tooling plate 19, and the frequency conversion compressor 17 is carried on the tooling plate 19; the rear side of the frame 1 is provided with a cabinet 15, and the middle part of the frame 1 is fixed with four One optical axis 2 and the jacking positioning mechanism 3 located in the middle of the four optical axes 2, the top of the four optical axes 2 is equipped with a gas-hydraulic booster cylinder pressing mechanism 4, and the middle and lower parts of the four optical axes 2 are installed with Press the centering mechanism 5, the top of the pressing and centering mechanism 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com