Oil spilling collecting device and method

A collection device and oil spill technology, which is applied in general water supply conservation, water conservancy projects, and open water surface cleaning, etc., can solve the problems of good marine oil spill collection effect, poor oil spill collection effect, etc., and achieves good scraping effect, Complete collection and good collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

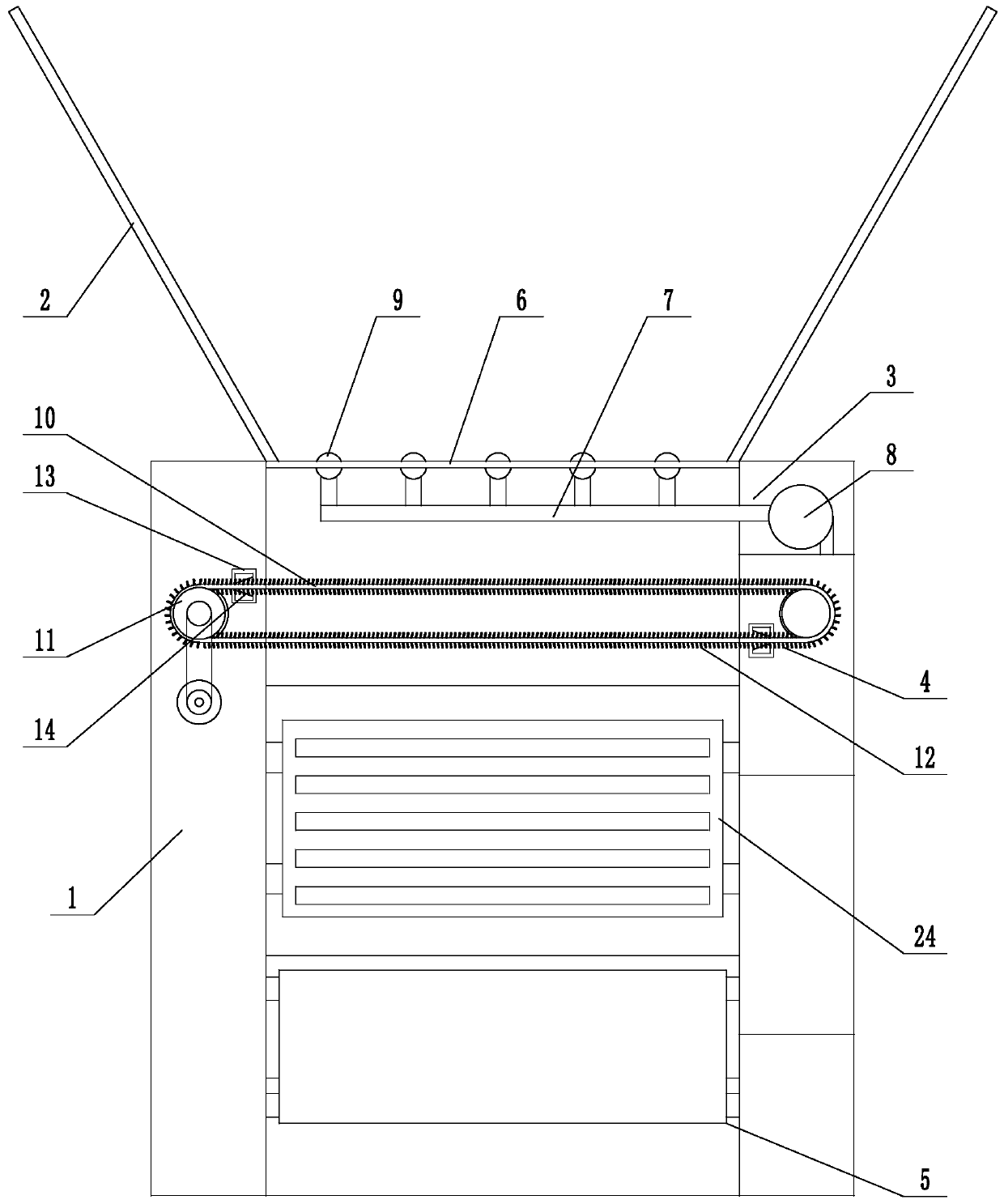

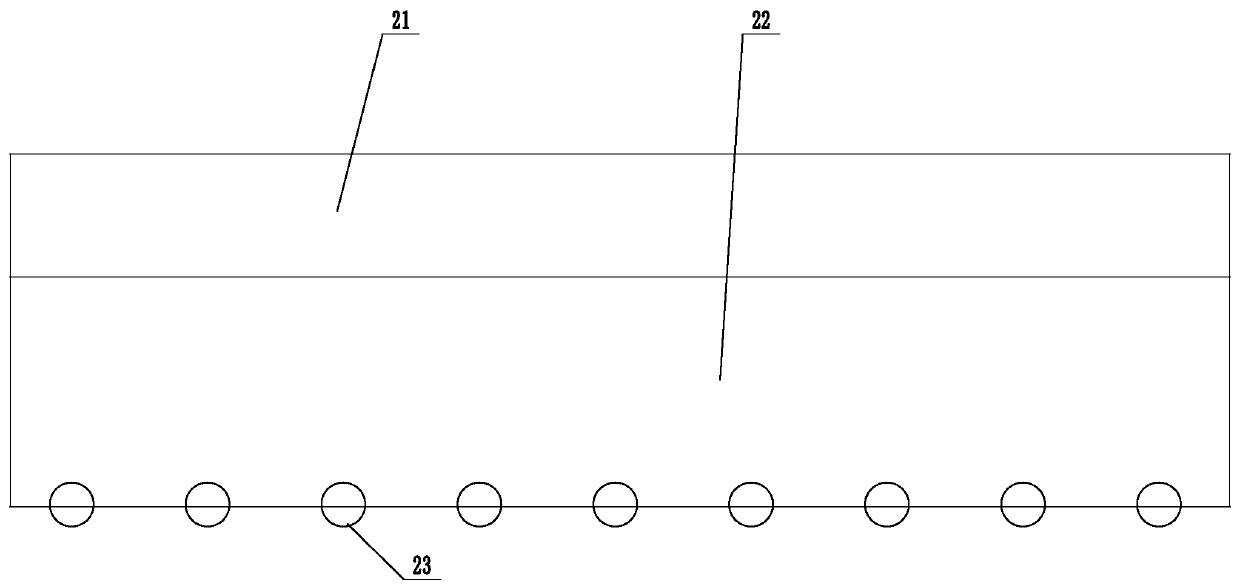

[0023] Example 1: An oil spill collection device (see attached figure 1 Attached image 3 ), including two oppositely arranged floating bodies 1, an oil guide float rod connected to the front end of the floating body 2, an oil suction mechanism 3, a front stage collection mechanism 4, a rear stage collection mechanism 5, and an oil suction mechanism installed between the two floating bodies from front to back. It includes a floating beam 6, an oil suction pipe 7, and an oil suction pump 8, which are placed between the two floating bodies. A row of suction heads 9 are installed on the floating beam. The suction heads are all connected to the oil suction pipe, and the oil suction pipe is connected to the suction pump; the front-stage collection mechanism includes a collection rope 10. Two guide wheels 11, the collection rope drive is connected between the two guide wheels, the collection rope is placed on the water, one guide wheel is connected to the output shaft of the front-stag...

Embodiment 2

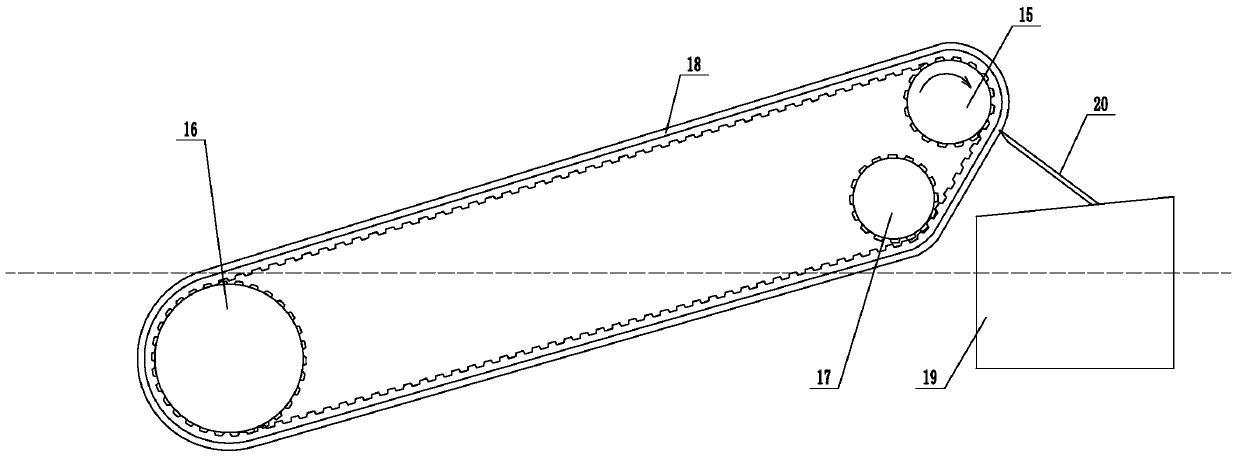

[0026] Example 2: An oil spill collection device (see attached figure 1 Attached Figure 4 ), its structure is similar to embodiment 1, the main difference is that the three-dimensional collection mechanism 24 is installed between the front-stage collection mechanism and the rear-stage collection mechanism in this embodiment. The three-dimensional collection mechanism includes an upper wheel 25, a lower wheel 26, and a driving wheel 27. , The upper wheel, the lower wheel, and the driving wheel are connected with a transmission belt 28 for transmission. The driving wheel is connected to the output shaft of the driving motor. The upper wheel and the driving wheel are placed above the water surface, the lower wheel is placed in the water, and the lower wheel is placed in front of the upper wheel. Below, the outer surface of the transmission belt is connected with a number of oil-bearing plates 29 at intervals. The oil-bearing plates are densely covered with a number of fine filteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com