Method for removing excess maceration extract from honeycomb support catalyst and its equipment

A technology of honeycomb carrier and excessive impregnation, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of large liquid loss and troublesome collection, and achieve the effect of convenient operation and simple process

Inactive Publication Date: 2003-07-09

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the process is simple and easy, there are still many inconveniences. One of the most prominent drawbacks is the trouble of collecting and the loss of more liquid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

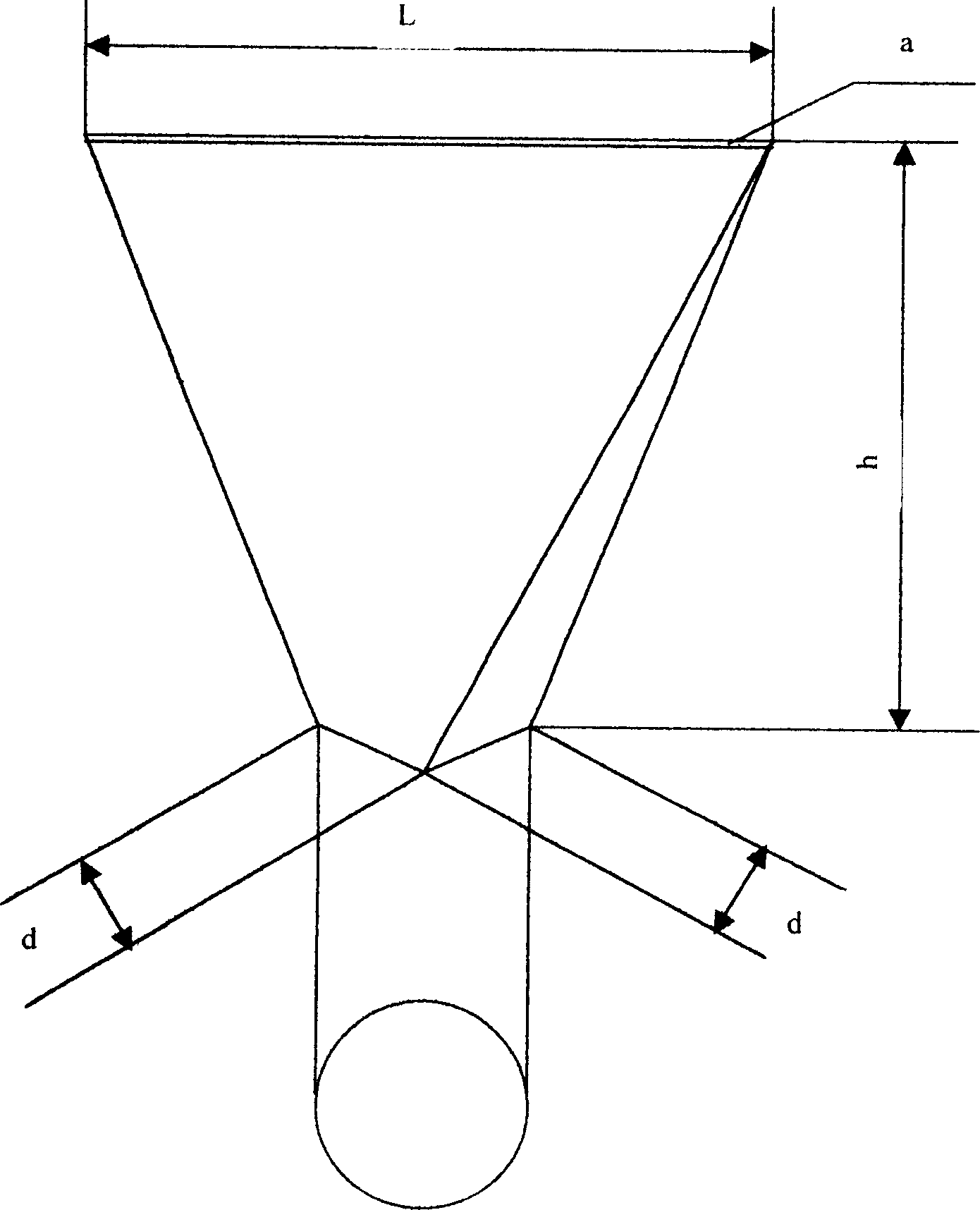

[0034] φ100mm×100mm 400 holes / inch 2 Honeycomb ceramics 3 catalyst glue viscosity 2800 centipoise d = 1.1

[0035] Honeycomb Ceramics

Embodiment 2

[0037] φ100mm×100mm 400 holes / inch 2 Honeycomb ceramics 3 catalyst glue viscosity 2800 centipoise d = 1.1

[0038] Honeycomb Ceramics

Embodiment 3

[0040] φ100mm×100mm 400 holes / inch 2 Honeycomb ceramics 3 catalyst glue viscosity 2800 centipoise d = 1.1

[0041] Honeycomb Ceramics

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

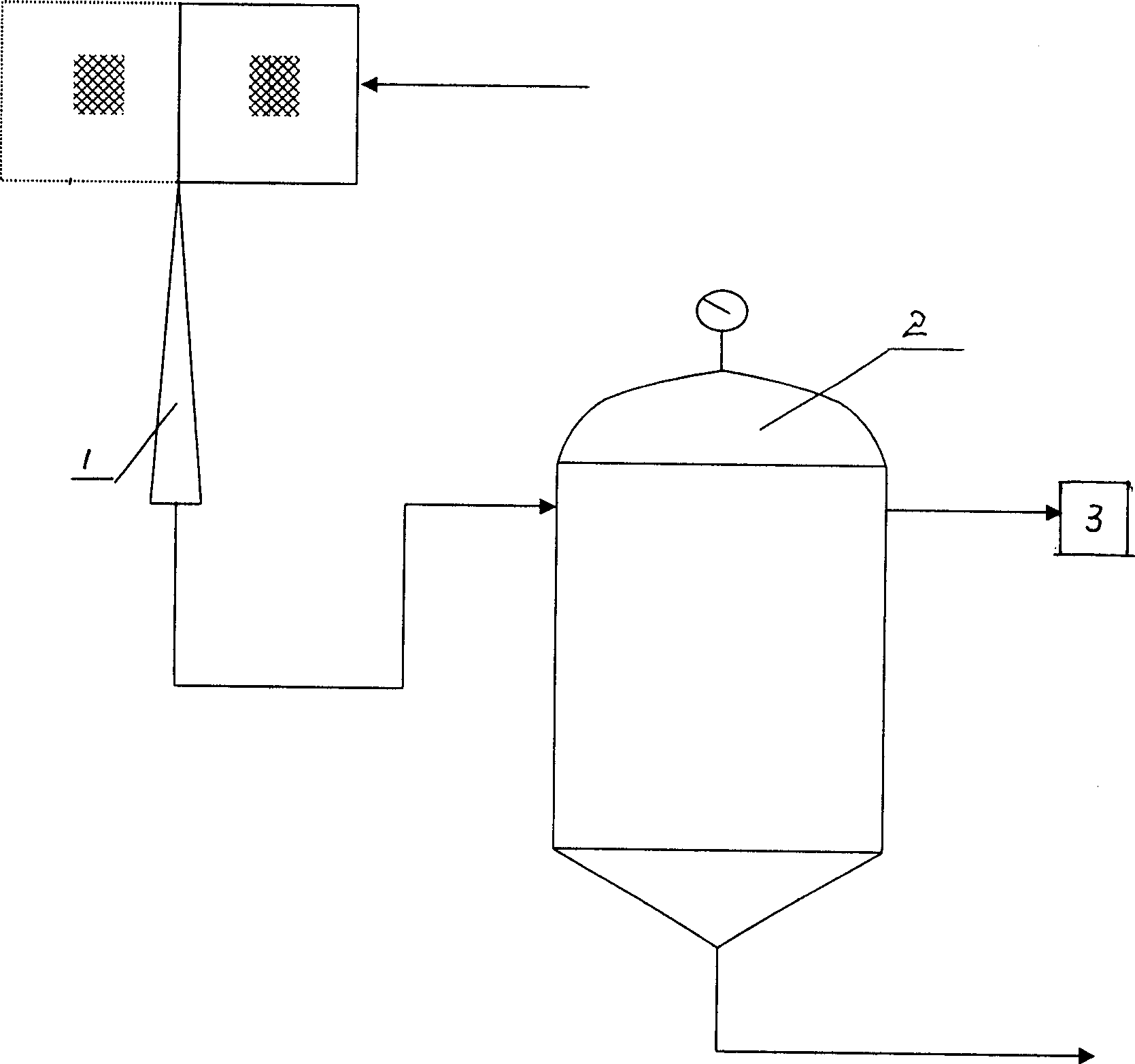

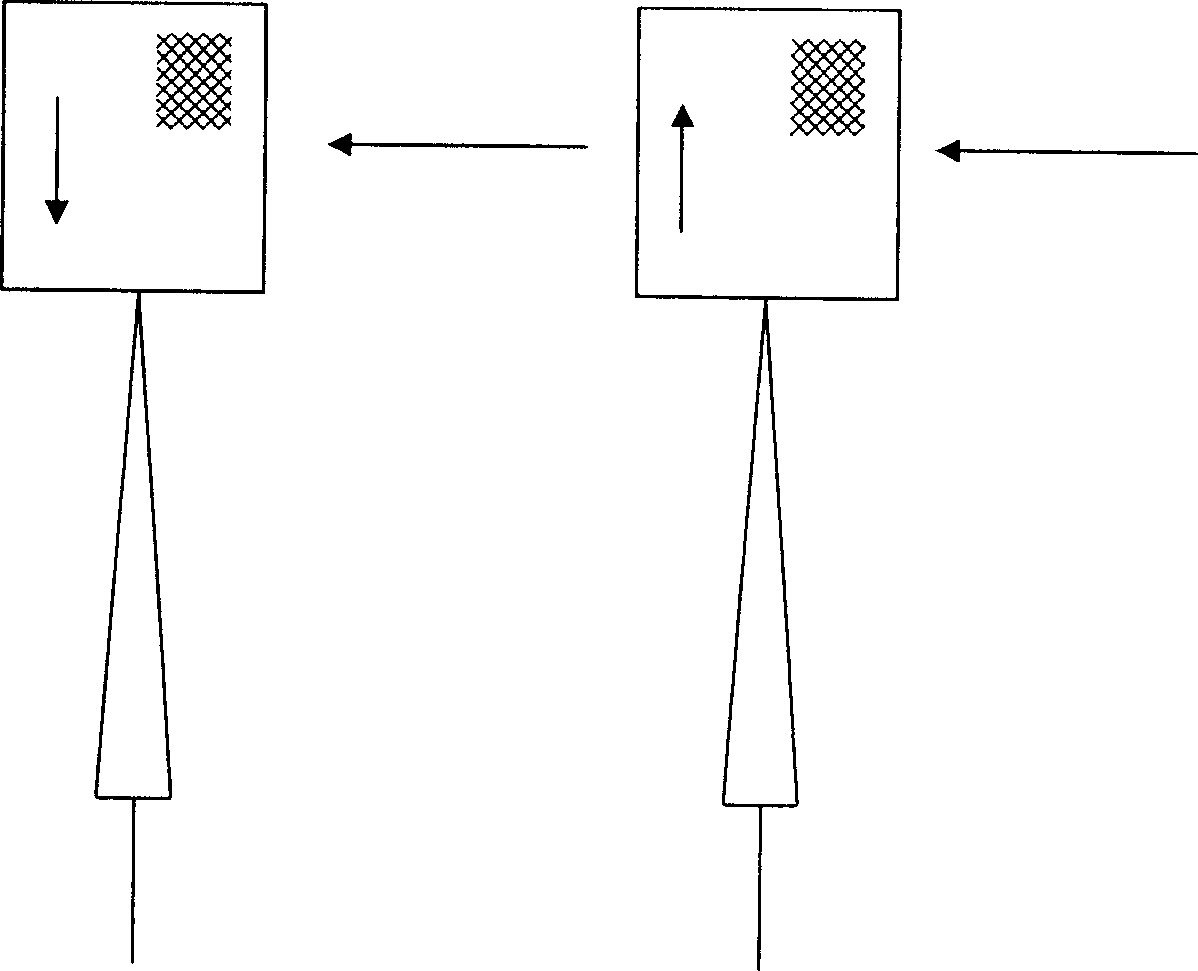

The present invention relates to a method for removing excess impregnation liquor of honeycomb carrier catalyst and its equipment. It adopts a vacuum negative-pressure mode to remove colloidal liquor or liquid, and is characterized by that it makes the linear suction nozzles equidistantly and uniformly scan and pass through one surface of the impregnated honeycomb carrier, then the above-mentioned operation is repeated on the opposite surface of said honeycomb carrier. Said method can effectively and completely remove the excess colloidal liquor or solution, and can completely collect it, so that it can make prepared catalyst have uniform coating layer, and is suitable for continuous production of noble metal catalyst.

Description

Technical field: [0001] The invention relates to catalyst preparation technology, and in particular provides a method for removing excess impregnation liquid of honeycomb carrier catalyst. Background technique: [0002] The preparation of monolithic honeycomb carrier catalyst usually adopts the method of excessive impregnation. The coating of the catalyst carrier alumina membrane and the coating of the active components are mostly done by impregnation. Such as US Patent 4,208,454; Chinese Patents CN87106740A, CN1054412A, CN1160599A. Taking honeycomb ceramics as an example, during the impregnation process of excess liquid, due to the pipe wall effect of the honeycomb ceramic pores, some liquid cannot flow out naturally, and must be forced out by pumps, compressed air or centrifugal methods, and finally compressed air Purge clean. Although the process is simple and easy, there are still many inconveniences. One of the most prominent drawbacks is troublesome collection and m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J35/04B01J37/02

Inventor 李恒强王树东陈光文夏元有

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com