Fluidized bed drying equipment

A fluidized bed drying and equipment technology, applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc., can solve the problems of inability to separate, mass transfer, and insufficient heat transfer effect, and achieve complete functions and thermal energy High utilization rate and effect of dust reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

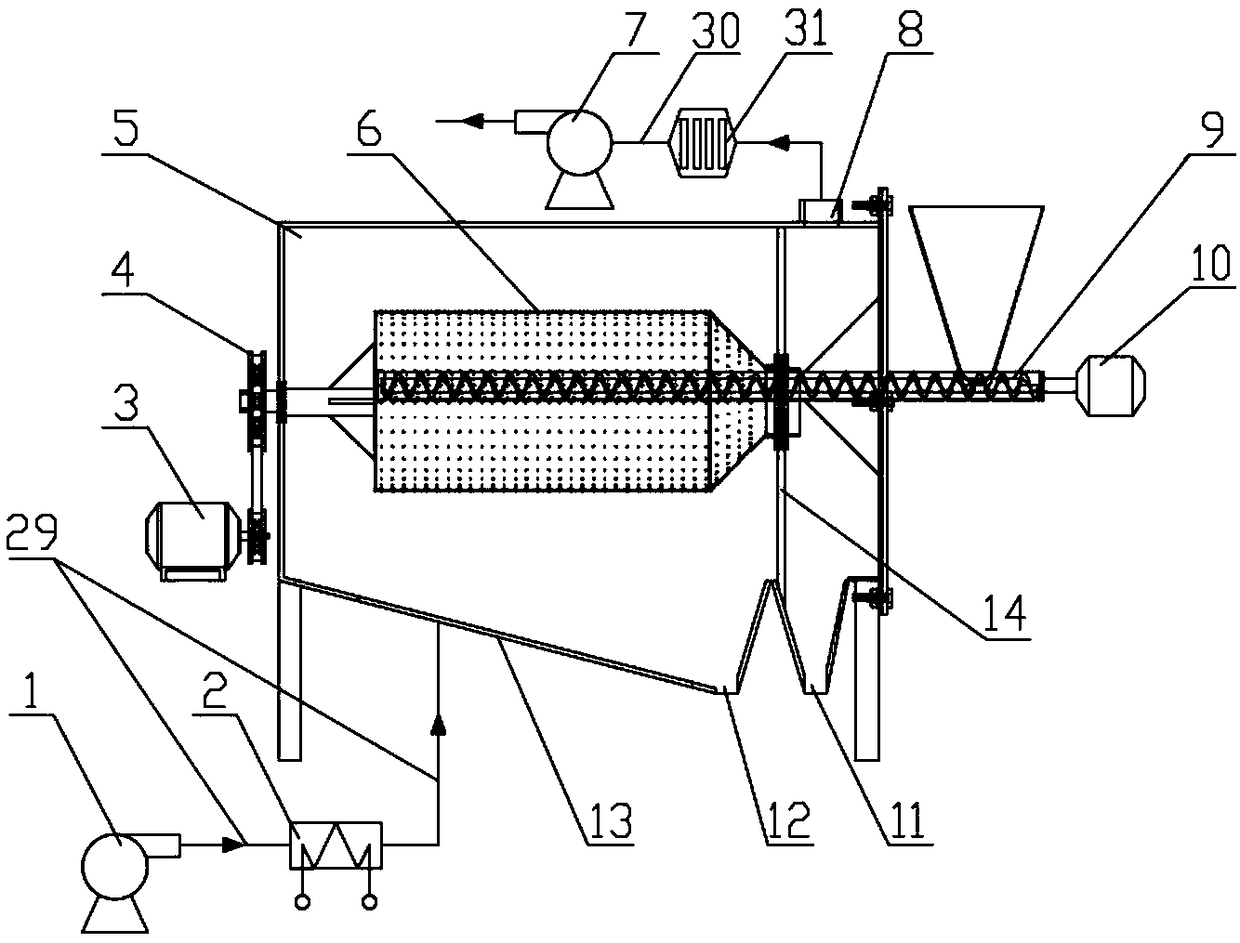

[0031] This embodiment is a fluidized bed drying equipment.

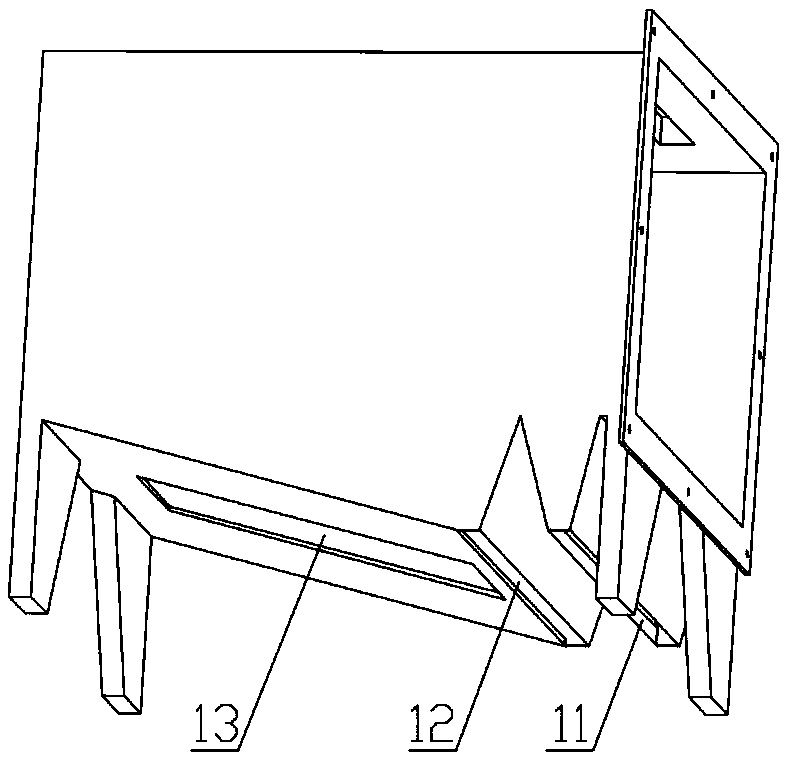

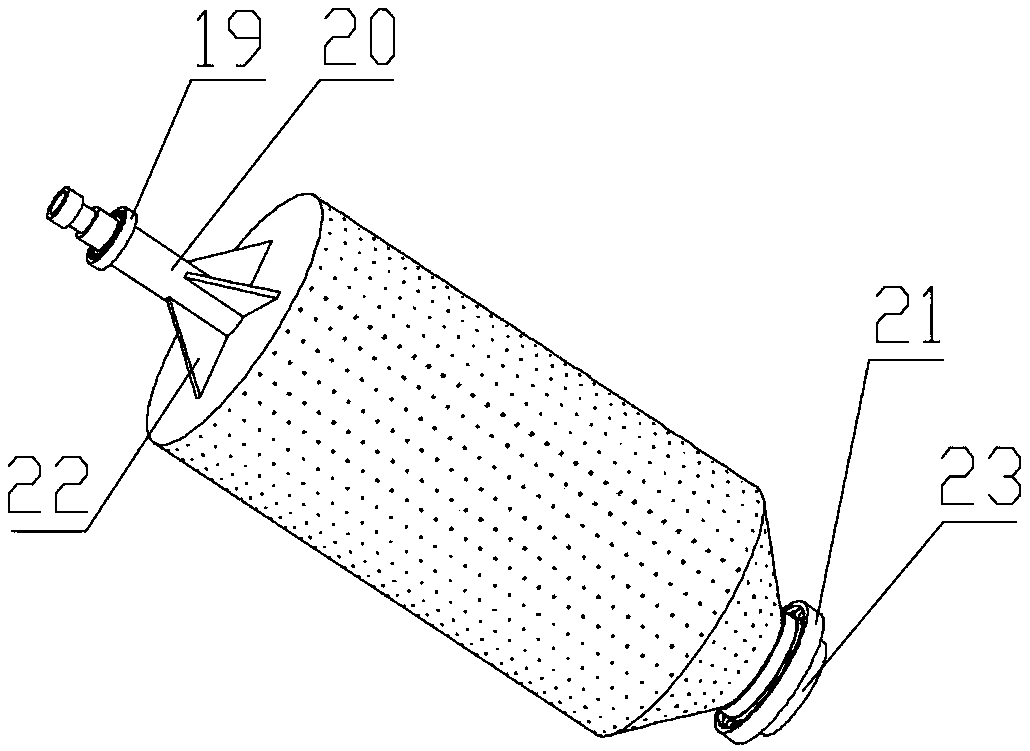

[0032] refer to Figure 1 to Figure 7 , The fluidized bed drying equipment of this embodiment is composed of an air compressor 1, an electric heating device 2, a first motor 3, a transmission device 4, an induced draft fan 7, a dust removal device 31, a PLC controller 27, a temperature sensor 28, and a support plate 14 , an end cover 17, a baffle plate 25, a box body 5, a drying separation device and a screw feeding mechanism 9; wherein, the box body 5 is a cavity cuboid structure, one end is a closed end, and the middle part of the closed end has a shaft hole for installation The drum shaft 20, the other end is an open end and is fixedly connected with the end cover 17; the bottom plate of the box body is provided with a slope along the axial direction, and the angle between the bottom plate of the box body and the horizontal plane is θ=15°~20°, which is used to make the dried The material flow is delivered to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com