Electric-cooling liquid mixed fuel heating system

A heating system and coolant technology, applied in the direction of charging system, fuel heat treatment device, combustion air/combustion-air treatment, etc., can solve the problems of low-temperature cold start of commercial diesel vehicles, reduce the use cost, improve low-temperature cooling The effect of starting performance and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

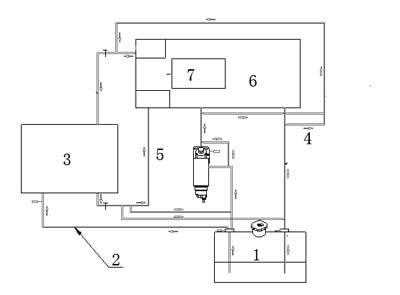

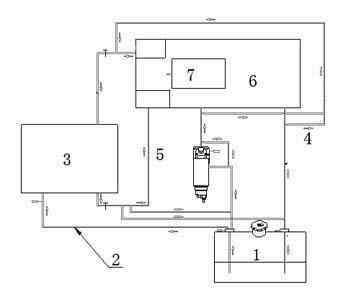

[0009] The present invention will be further described below in conjunction with the accompanying drawings: figure 1 As shown, the electric and coolant mixed fuel heating system is characterized by: electric heating is provided on the oil suction pipe and the oil return pipe on the fuel tank assembly 1, the heater oil pipe 2, the coarse filter 5, and the fine filter 7 on the engine 6. One end of the heater oil pipe 2 is connected to the heater 3, and the other end is connected to the oil suction pipe; a heating sleeve 4 is provided between the oil return pipe and the engine; a heating sleeve is provided between the coarse filter 5, the engine 6 and the oil suction pipe 4; The specific heating method is as follows: first use electricity to heat the oil tank suction pipe and return pipe, and use the electric heater to heat the oil delivery pipe 2. After the heater 3 works, the engine coolant is heated, and part of the engine coolant after heating (the ratio is 70%) It is allocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com