Novel water surface spilled oil collecting containment boom based on negative pressure principle

An oil boom and oil spill technology, which is used in general water supply conservation, open water surface cleaning, water conservancy projects, etc., can solve the problem of low processing rate, inability to deal with oil spills in a timely manner, and increased uncertainty in the area of oil spills Factors and other issues, to achieve high application value, solve the problem of oil spill pollution and spread, and the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

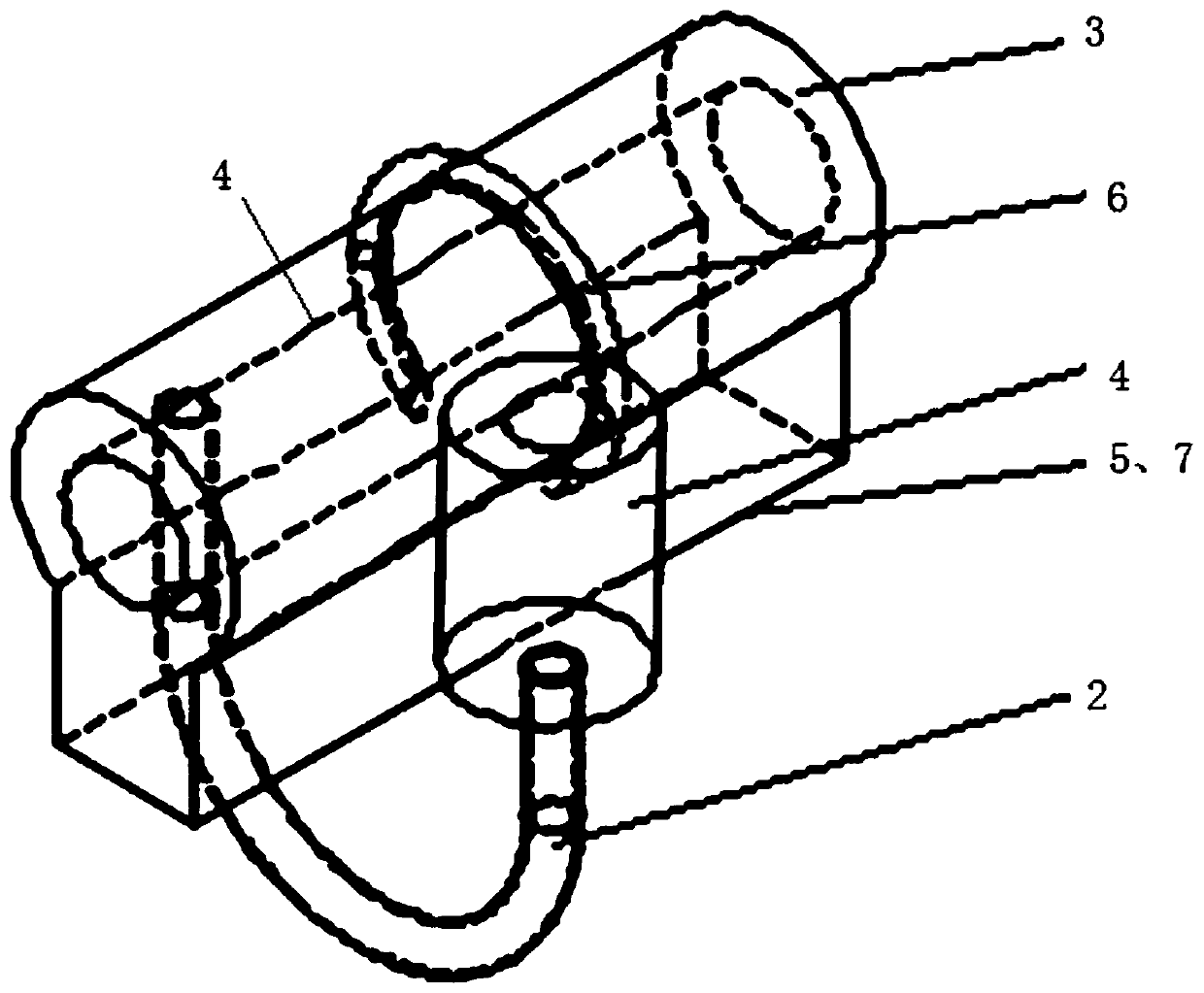

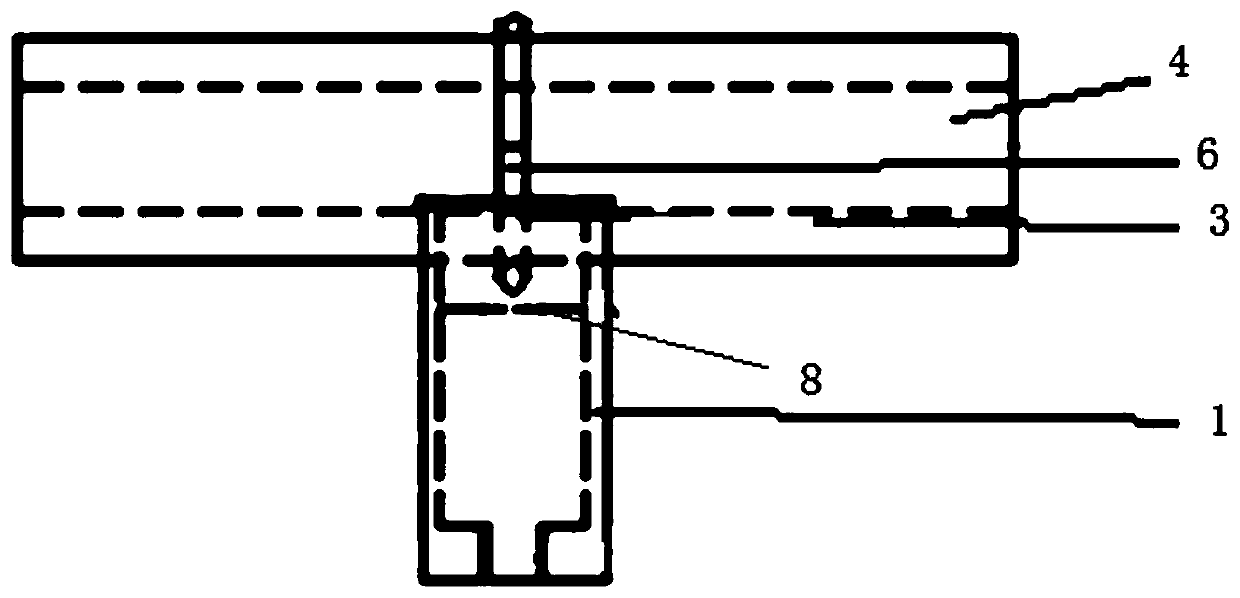

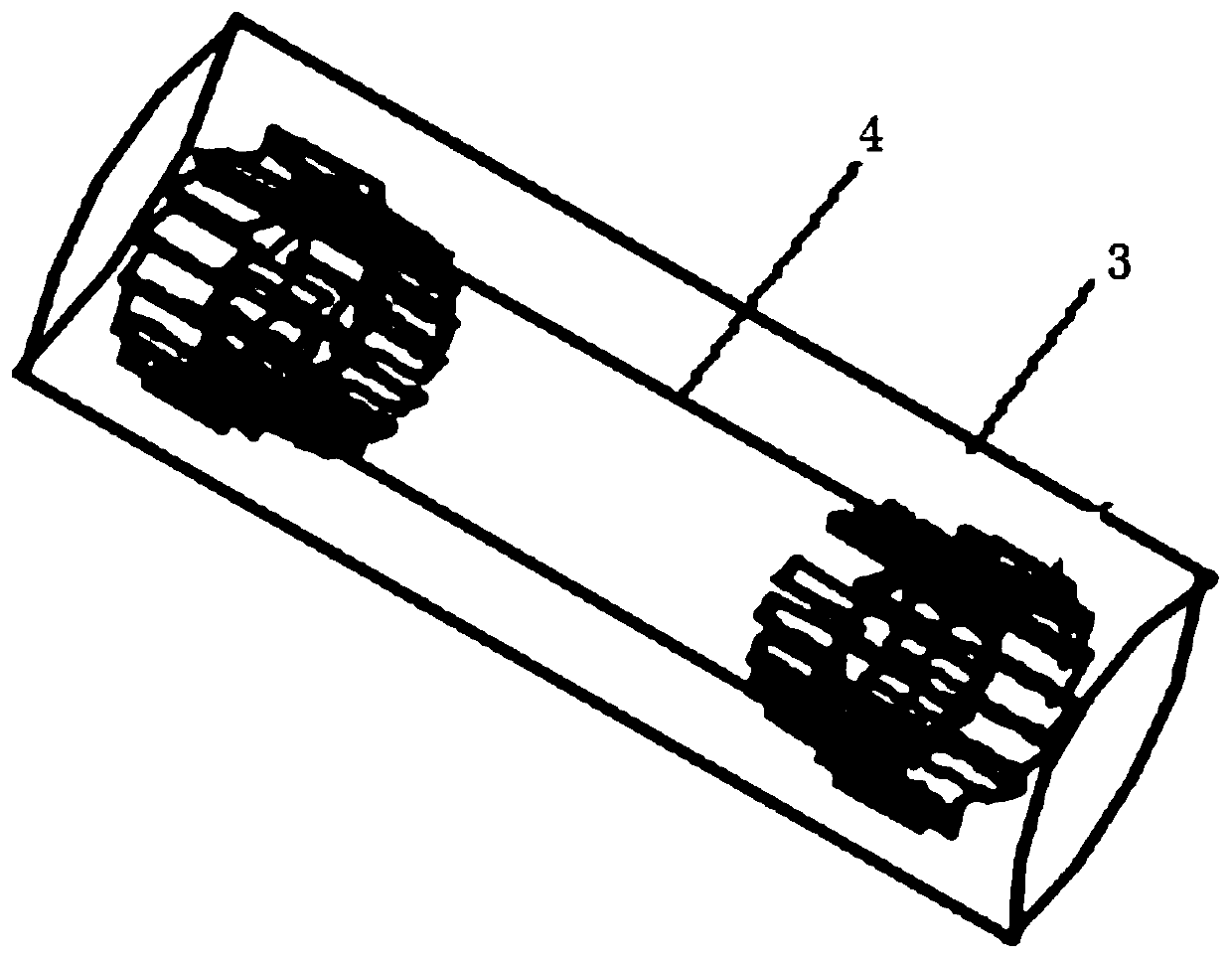

[0023] Such as Figure 1 to Figure 3 , Image 6 Shown is a novel water surface oil spill collection oil boom based on the principle of negative pressure, comprising a water surface oil spill collector, an oil containment boom, a negative pressure pump 11 and a ship rapid oil-water separation device 12, the water surface oil spill collector Including a barrel body 1 and an oil suction pipe 2, the top of the barrel body 1 is provided with an oil inlet, the bottom of the barrel body 1 is provided with a round hole, the round hole is connected with the oil suction pipe 2, and the oil inlet at the top of the barrel body 1 is provided with a There is a height regulator, which will rise or fall with the change of oil volume or buoyancy, so that the oil inlet is always above the water surface and below the oil surface. The oil containment boom include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com