Oil pump driving system for diesel engine

A diesel engine and transmission system technology, applied in the direction of pressure lubrication of machines/engines, mechanical equipment, lubricating pumps, etc., can solve the problem of reducing the oil pumping capacity of the oil pump, increasing the difficulty of designing and processing the gear chamber, gear chamber cover, and the exterior of the diesel engine The problem of narrow space and other problems can be achieved by reducing the difficulty of design and manufacturing, eliminating flow resistance, and improving the pumping capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

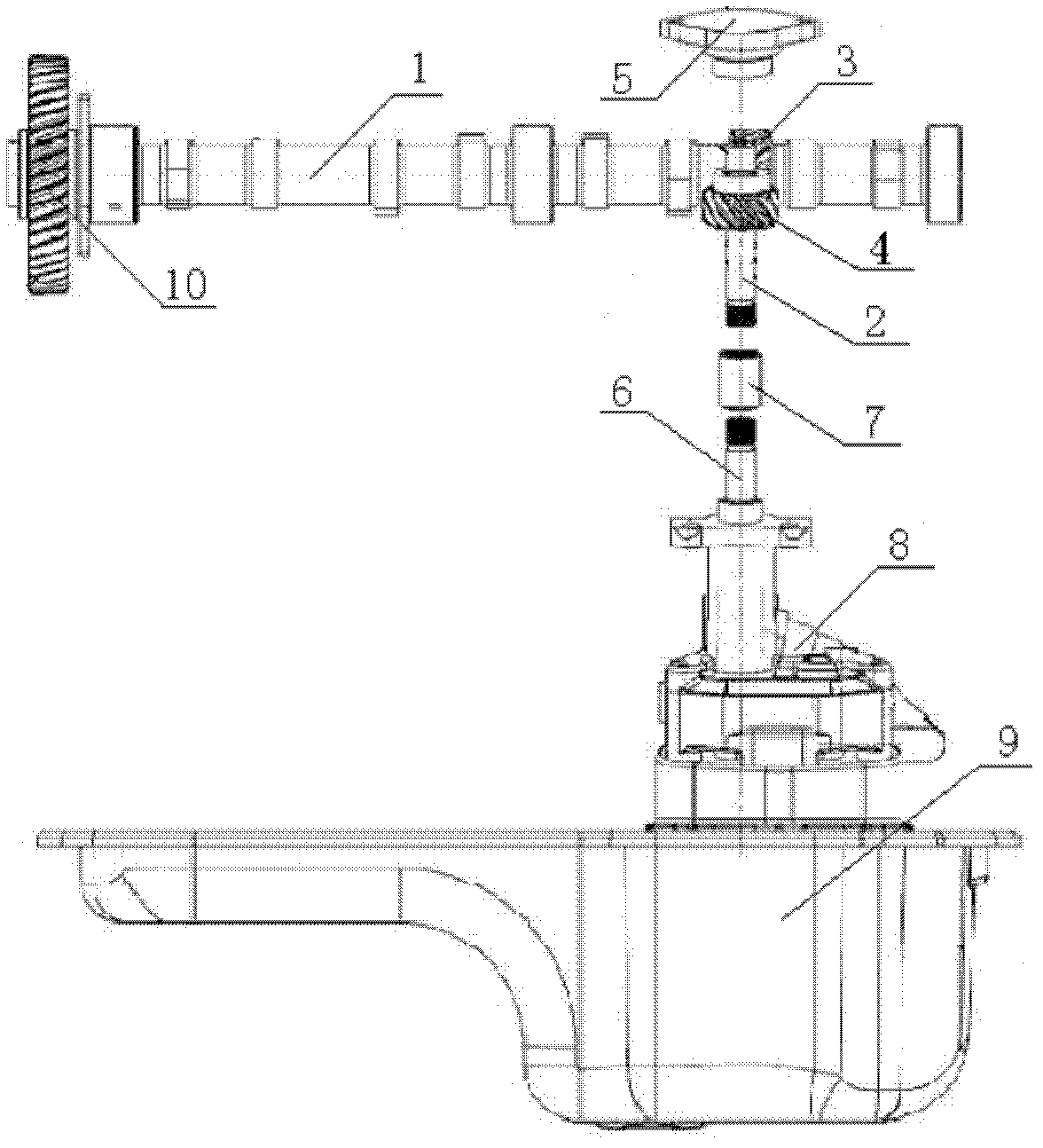

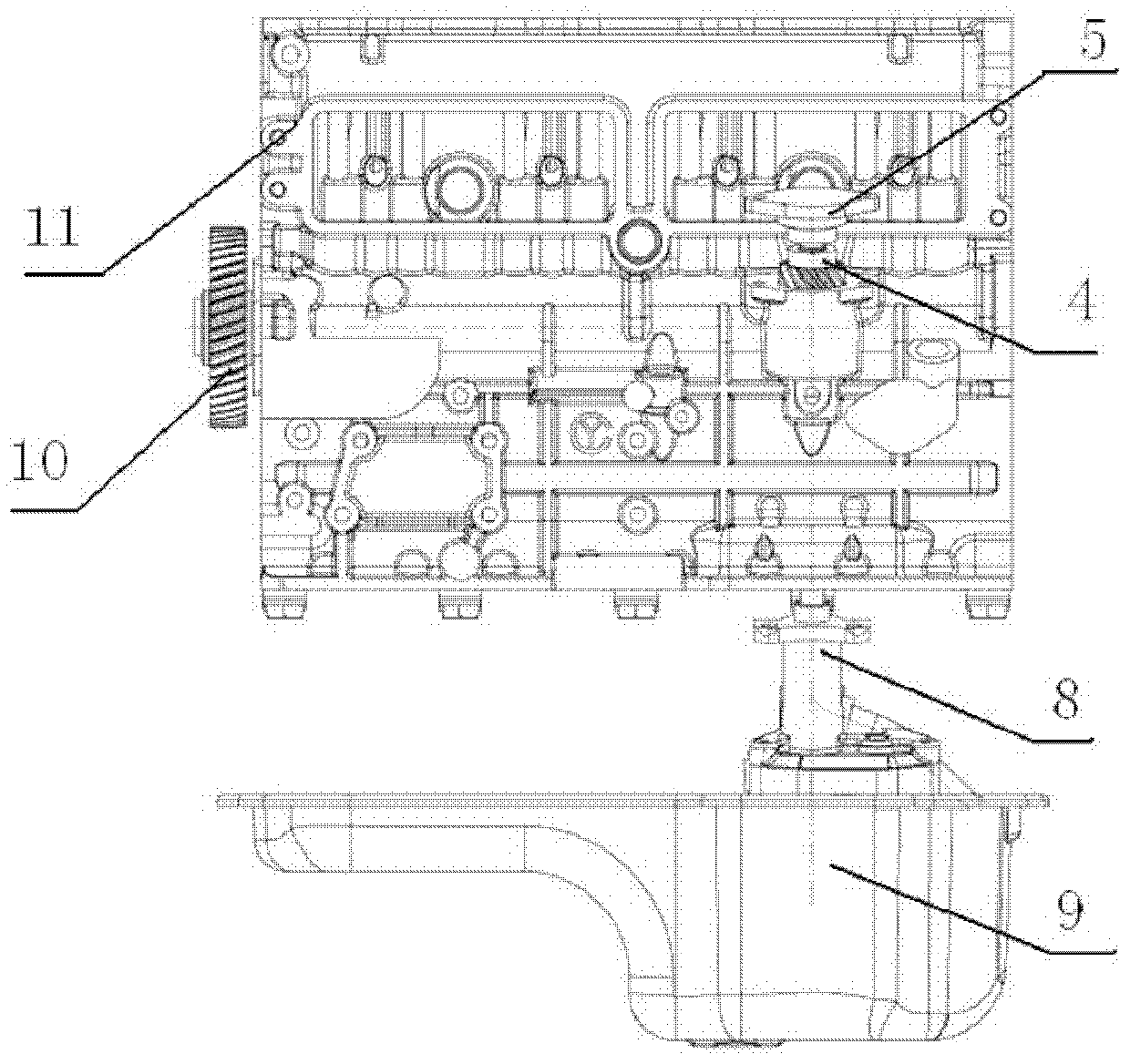

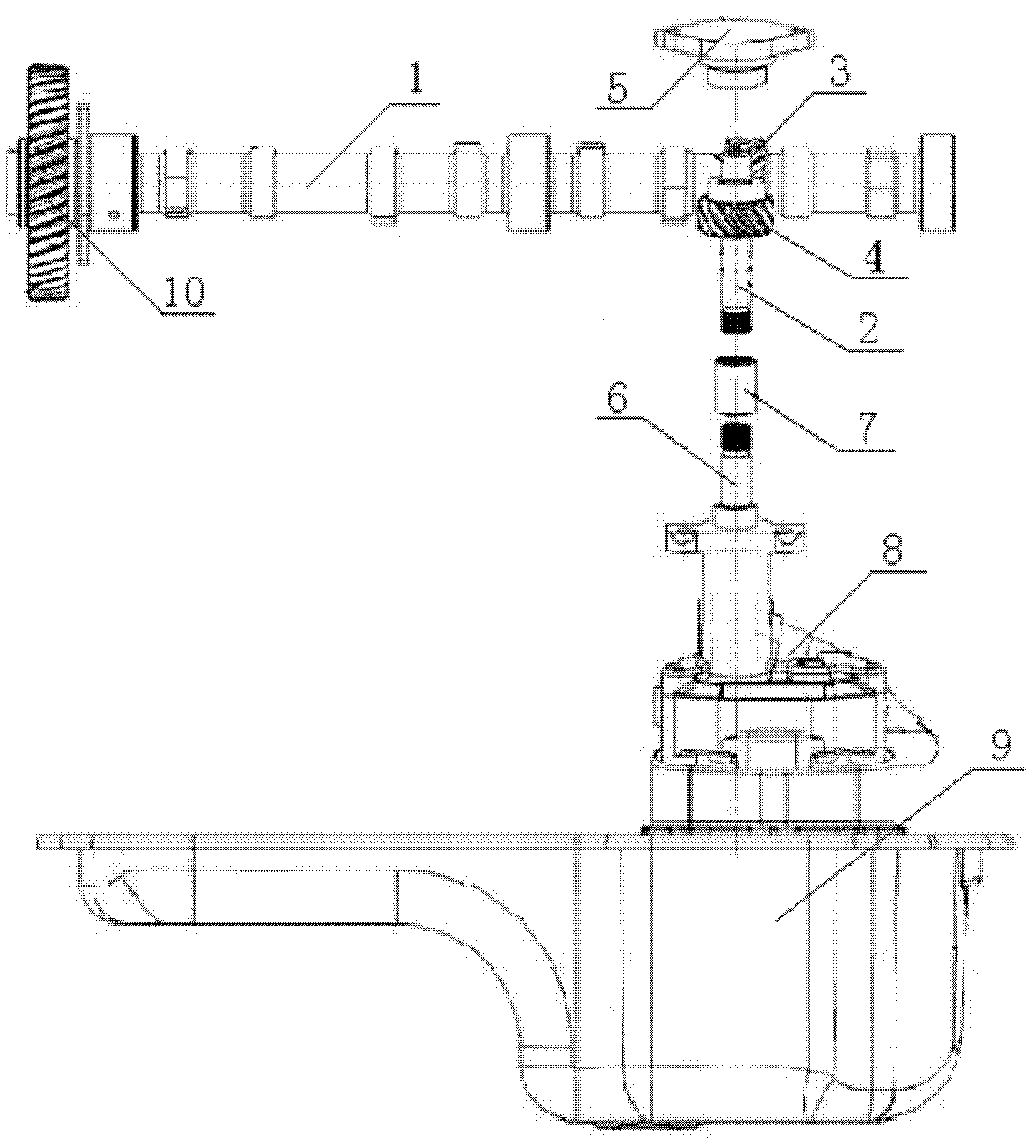

[0009] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments. The diesel engine oil pump transmission system has the following structural features: the camshaft 1 is connected to the oil pump transmission shaft 2 through a pair of intermeshing helical gears, the horizontal side helical gear 3 is connected to the camshaft; the vertical side helical gear 4 is connected to the oil pump transmission shaft . One end of the transmission shaft of the oil pump is an optical shaft, and the optical shaft is inserted into the transmission shaft cover 5; The oil pump 8 is placed in the oil pan 9 . The crankshaft gear of the diesel engine drives the camshaft gear 10 to rotate, and the camshaft operates according to the valve timing. The transmission shaft cover 5 is provided with an oil passage near the side of the vertical side helical gear 4, and relies on the oil splash carried by the helical gear body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com