Multi-path valve for wheel excavator

A technology for excavators and multi-way valves, which is applied to earth movers/shovels, construction, etc., and can solve problems such as excessively fast rotating motor speed, poor operating comfort, and long strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

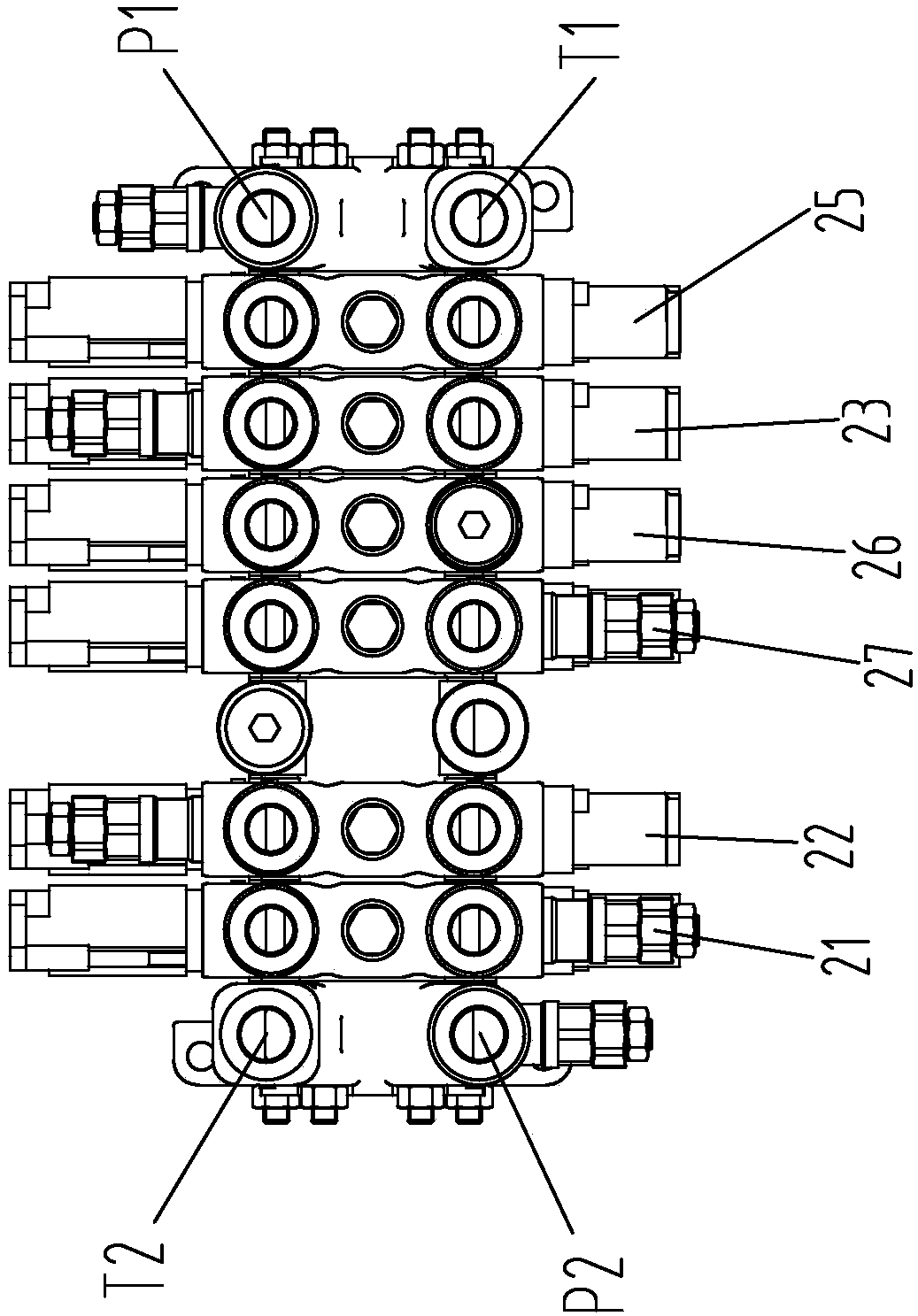

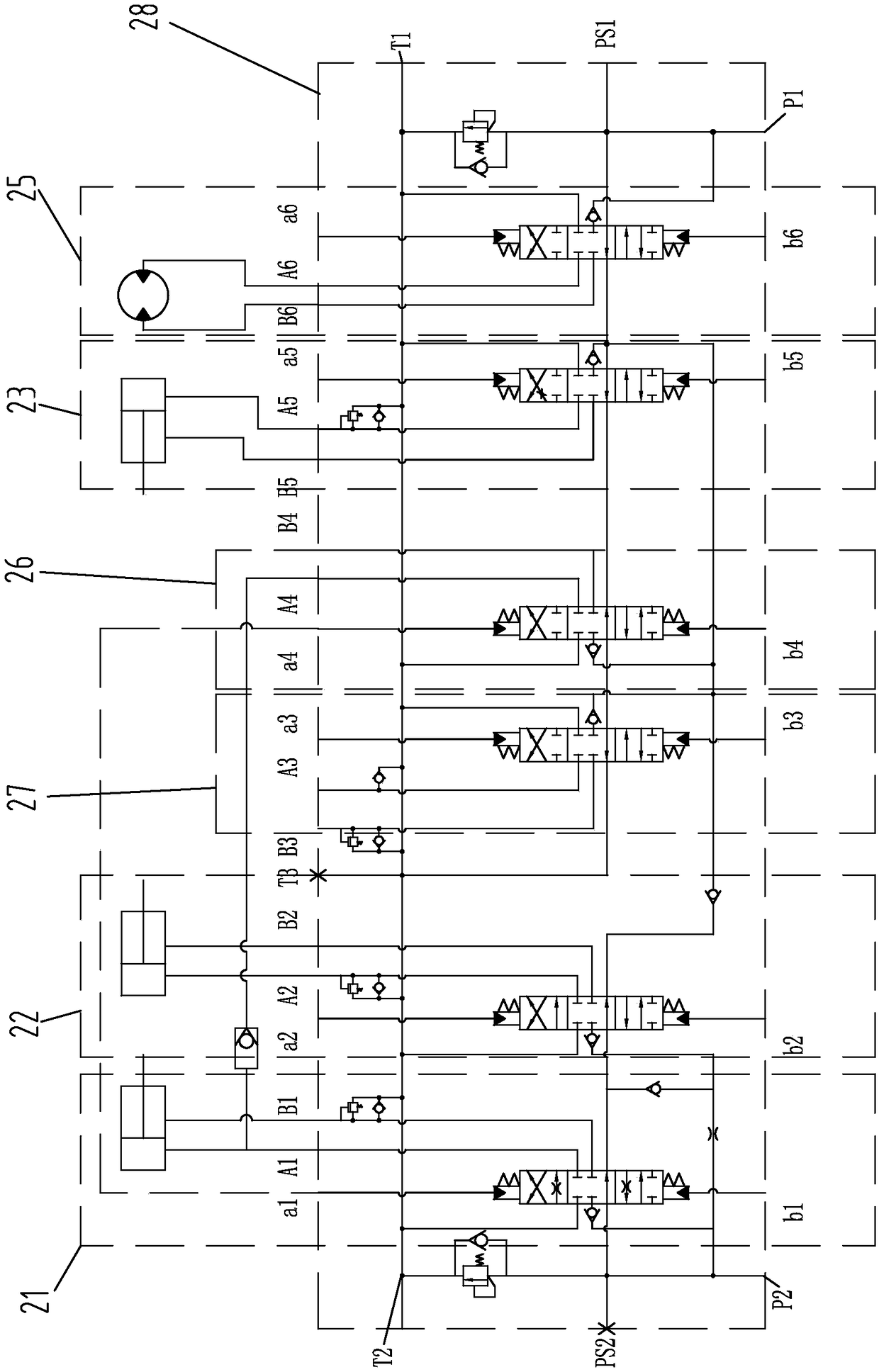

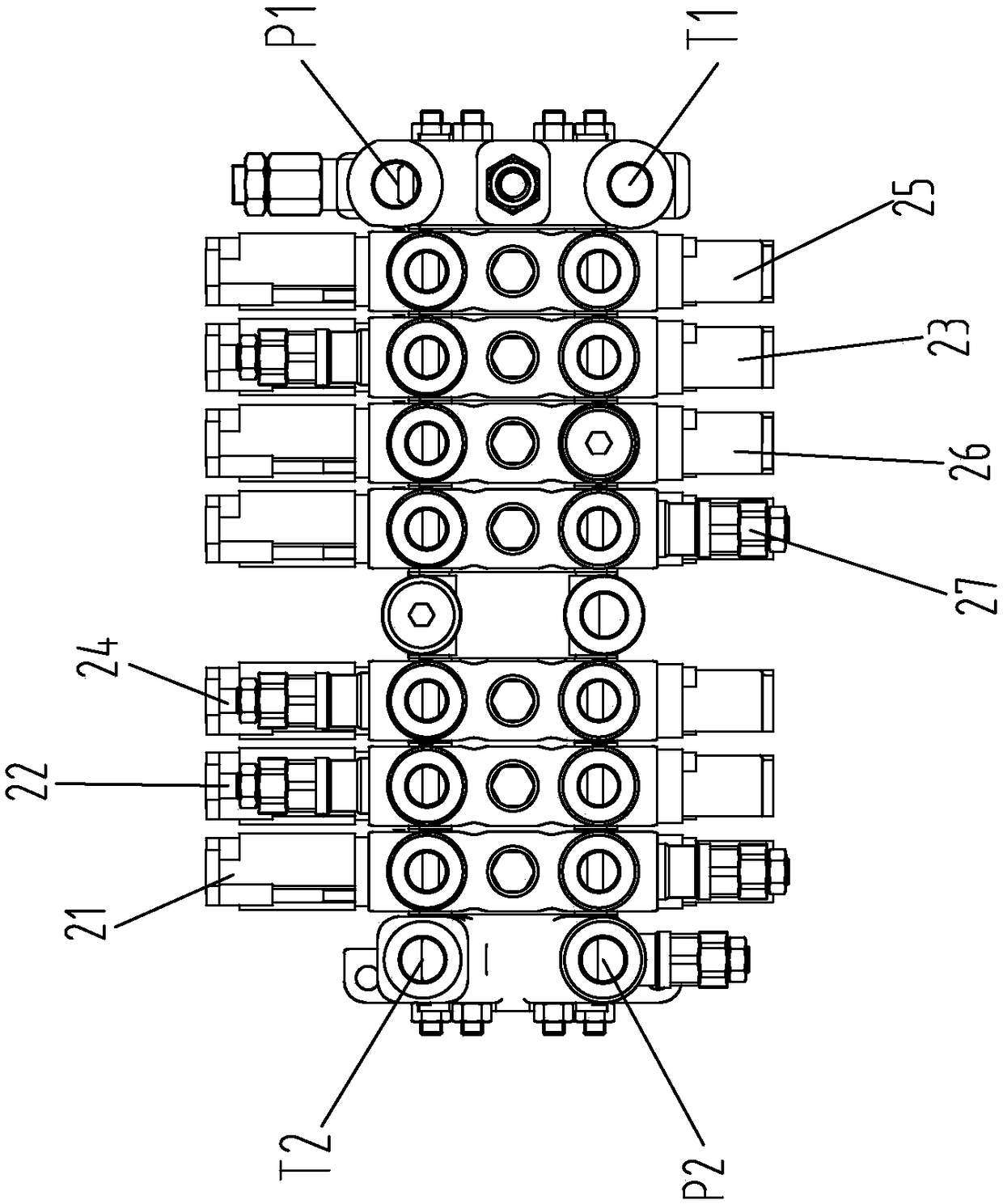

[0043] Such as Figure 1-7As shown, a multi-way valve for a wheeled excavator includes the first oil inlet P1 and the second oil inlet P2 connected to different hydraulic pumps, and the oil return port T connected to the oil return of the hydraulic system. The oil return port T includes the first oil return port T1 and the second oil return port T2, which are used to control the boom oil circuit 21 for swinging the boom, and the bucket oil circuit 22 for controlling the bucket excavation. The arm connecting oil passage 23 for controlling the swing of the arm and the pilot oil circuit 28 for controlling the inlet of the pilot oil, each oil passage is connected in series in turn and communicated with the second oil inlet P2 and the oil return port T to form a circuit , the first oil return port T1 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com