Carburetor provided with rotary valve and capable of being started rapidly

A rotary valve and carburetor technology, which is applied to carburetors, engine components, machines/engines, etc., can solve the problems of complex movement process and inconvenient use, and achieves simple process, increased oil intake, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

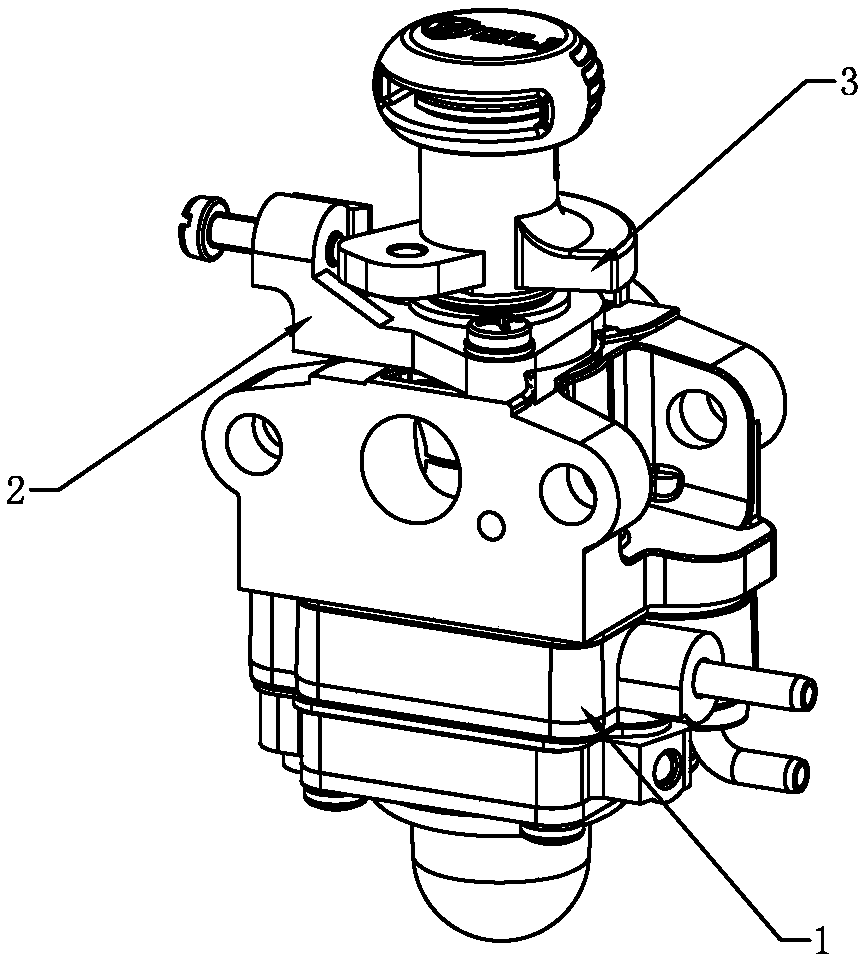

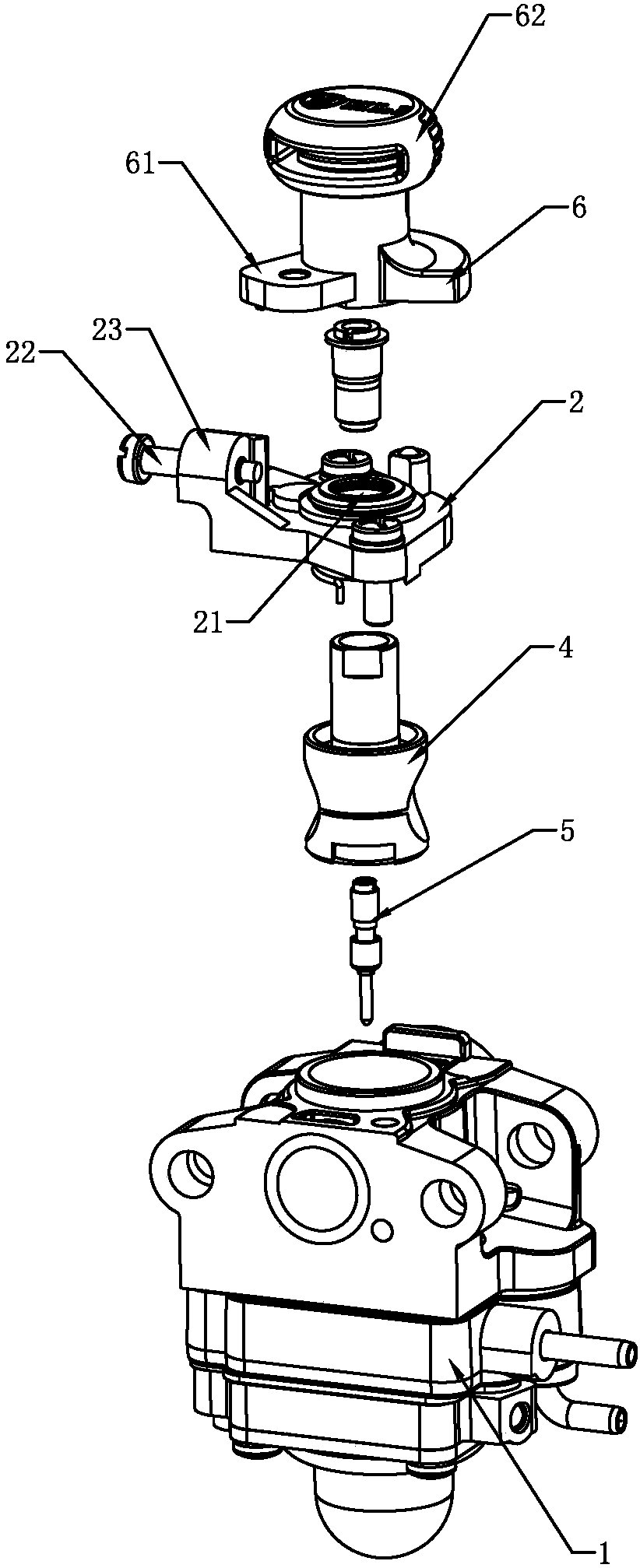

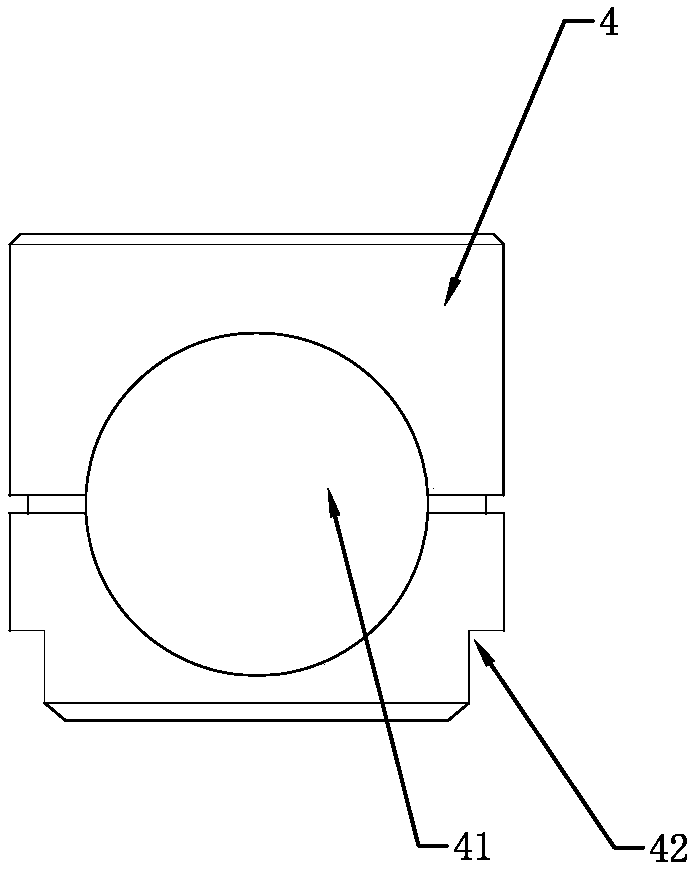

[0017] refer to Figure 1 to Figure 4 , a rotary valve carburetor that can be quickly started according to the present invention includes a carburetor body 1, a fixing frame 2, and a starting device 3. The fixing frame 2 is detachably arranged on the carburetor body 1, and the starting The device 3 includes a rotary valve 4 that can be rotated around the longitudinal axis to open or close the mixing channel. A cylindrical cavity 41 is provided on the rotary valve 4. On the outer wall perpendicular to the cylindrical cavity 41 on the rotary valve 4, there is also a There is a vent hole 42, the rotary valve 4 is provided with an oil needle 5 concentric with the rotary valve 4, the upper part of the rotary valve 4 is connected with a rocker arm 6 that can drive it to lift, and the rotary valve 4 and the rocker arm 6 pass through the fixing frame 2. The through hole 21 in the middle part is connected, and a return spring (not shown in the figure) is arranged between the rotary val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com