Ignition device and ignition method for combustor

An ignition device and burner technology, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of insufficient oil mist combustion, waste of energy, and generation of toxic substances, so as to improve energy utilization rate, improve combustion sufficiency, The effect of increasing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

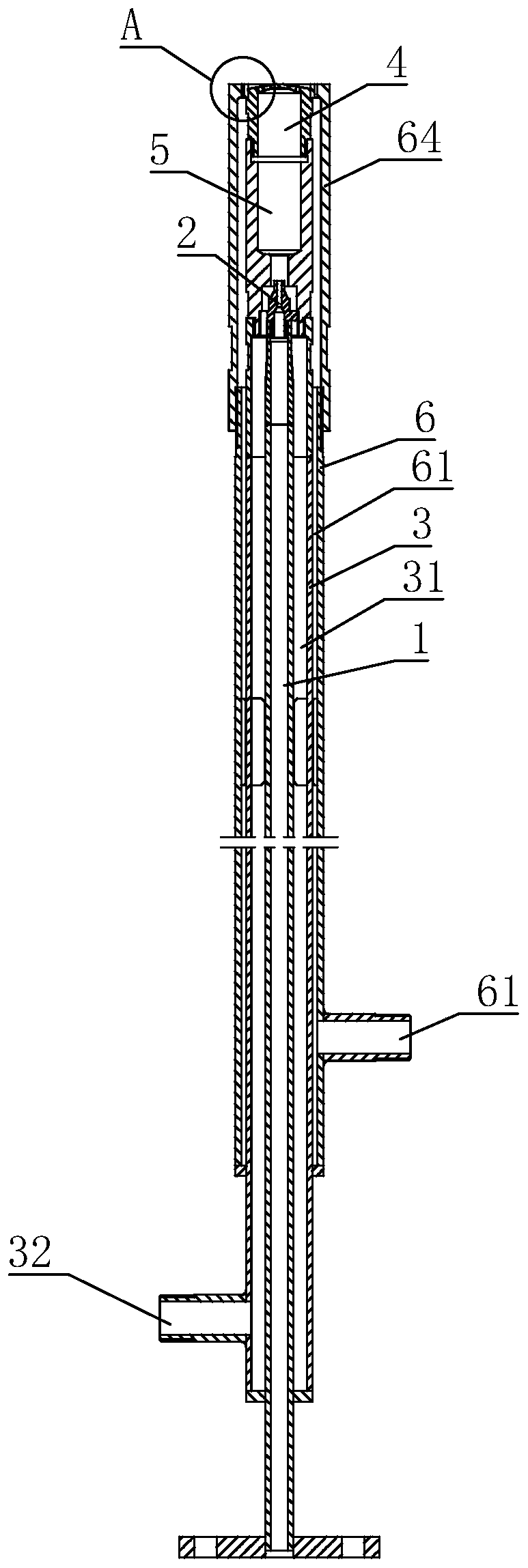

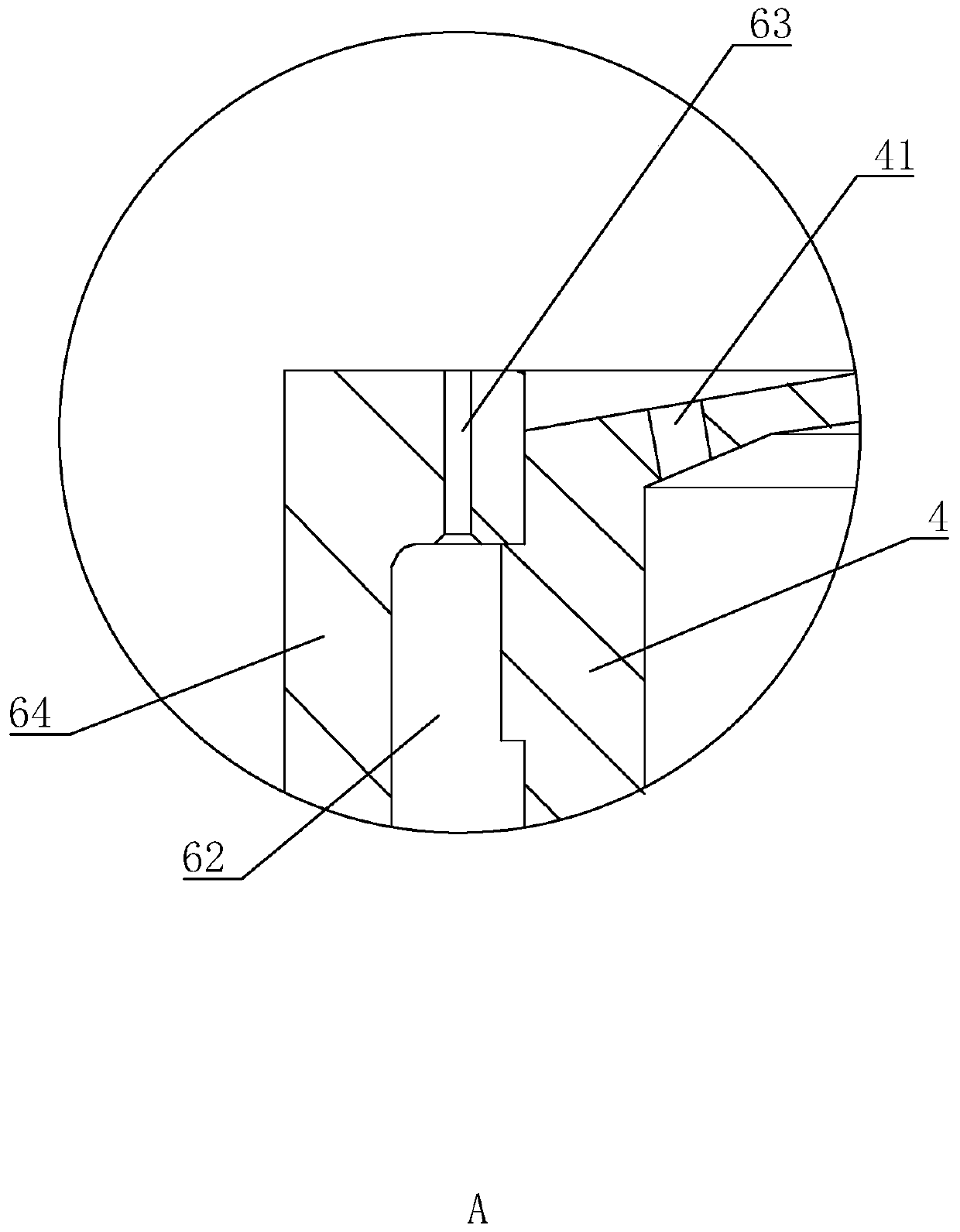

[0031] Embodiment: a kind of ignition device of burner, as figure 1 , including a round tubular oil pipe 1 and an inner air pipe 3 coaxially sleeved outside the oil pipe 1. At this time, an inner air cavity 31 is formed between the inner air pipe 3 and the oil pipe 1. One end of the oil pipe 1 is connected with a nozzle 2, and the inner air The end of the pipe 3 facing the oil nozzle 2 is set as the air outlet end, and the wall of the inner air pipe 3 away from the oil nozzle 2 is provided with a first air inlet 32 . The oil pipe 1 is filled with oil, and when the oil passes through the oil nozzle 2, it is dispersed into oil mist. At this time, the operator feeds air into the first air inlet 32, and the air passes through the inner air cavity 31 and flows out from the air outlet end of the inner air pipe 3. At this time, this part of the air is mixed with the oil mist, which increases the oxygen content around the oil mist.

[0032] Such as figure 1 The end of the inner ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com