Large gas cooking stove for cooking

A technology for large cookers and gas stoves, which is applied in household stoves, household stoves/stoves, applications, etc. It can solve the problems of poor utilization of flue gas waste heat, insufficient combustion of gas, and poor heating uniformity of large gas cookers to achieve uniform heating The effect of promoting and enhancing the fullness of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

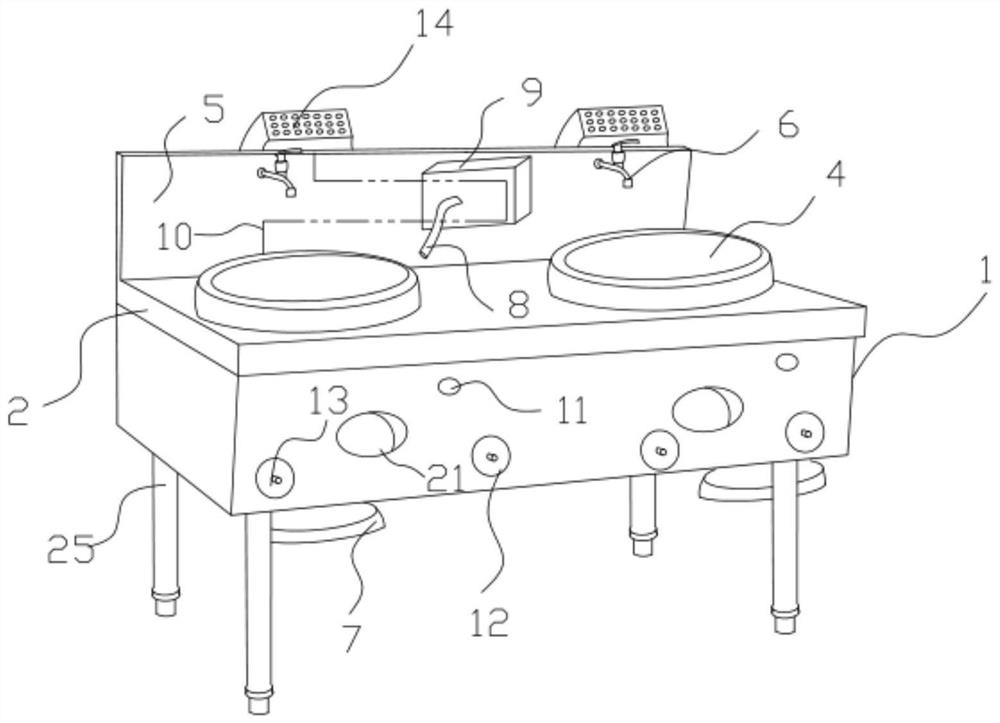

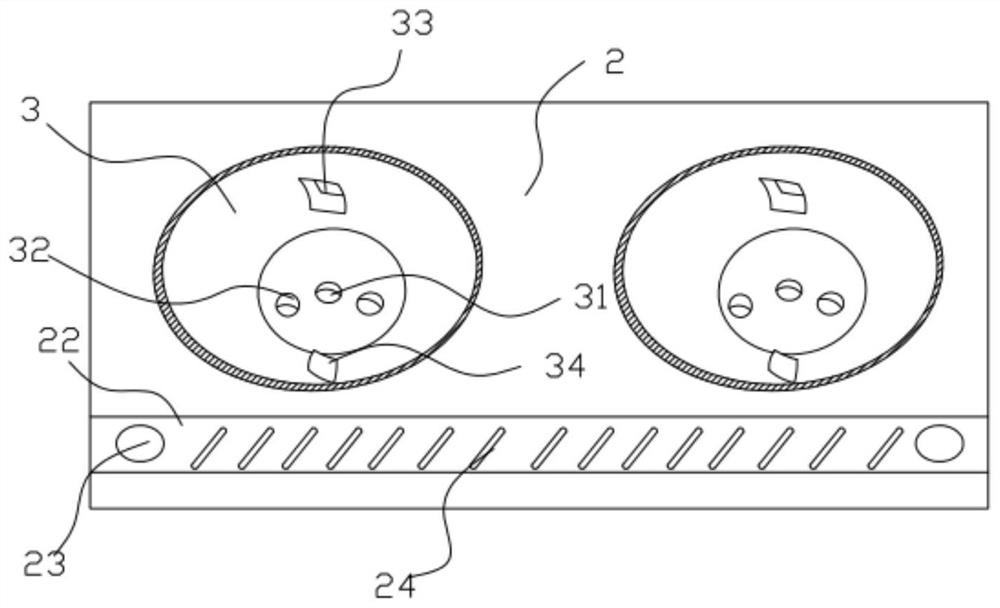

[0024] Such as Figure 1~3 As shown, this embodiment provides a large gas cooker for cooking. The gas cooker for cooking is centered on solving gas combustion sufficiency and improving the efficiency of heat and waste heat utilization, and is used to solve the problem of the existing large gas cooker. Existing problems.

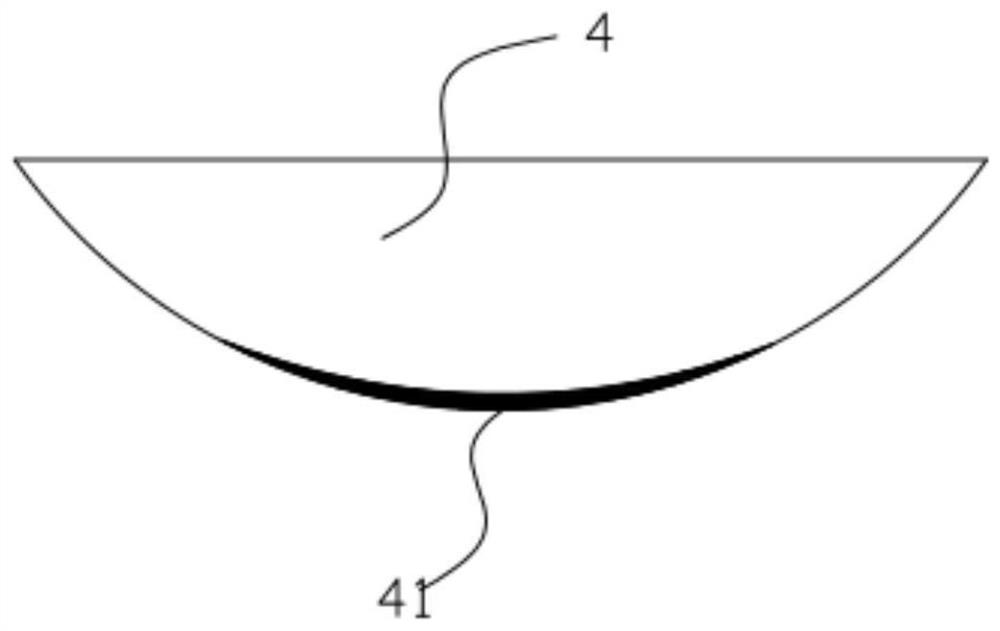

[0025] In this embodiment, the large gas cooker for cooking includes the main body of the large gas cooker. The main body of the large gas cooker is made of stainless steel and includes a workbench. There are two stove holes, each of which corresponds to a hearth, and the pot is set on the hearth, and the bottom of the hearth is the burner, and the burner is connected to the gas connector on the main body of the large gas boiler through the gas pipeline, and the gas connector is connected to the gas source; working There is a vertical board on the rear side of the table, also known as a windshield board. The vertical board is integrated with the main body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com